Physical Foam Sheet&Core Production Line

12

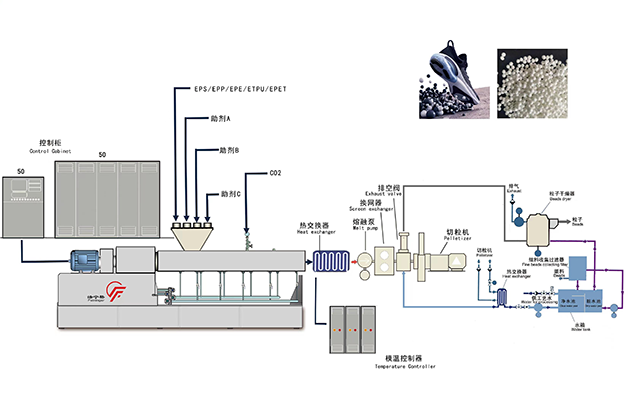

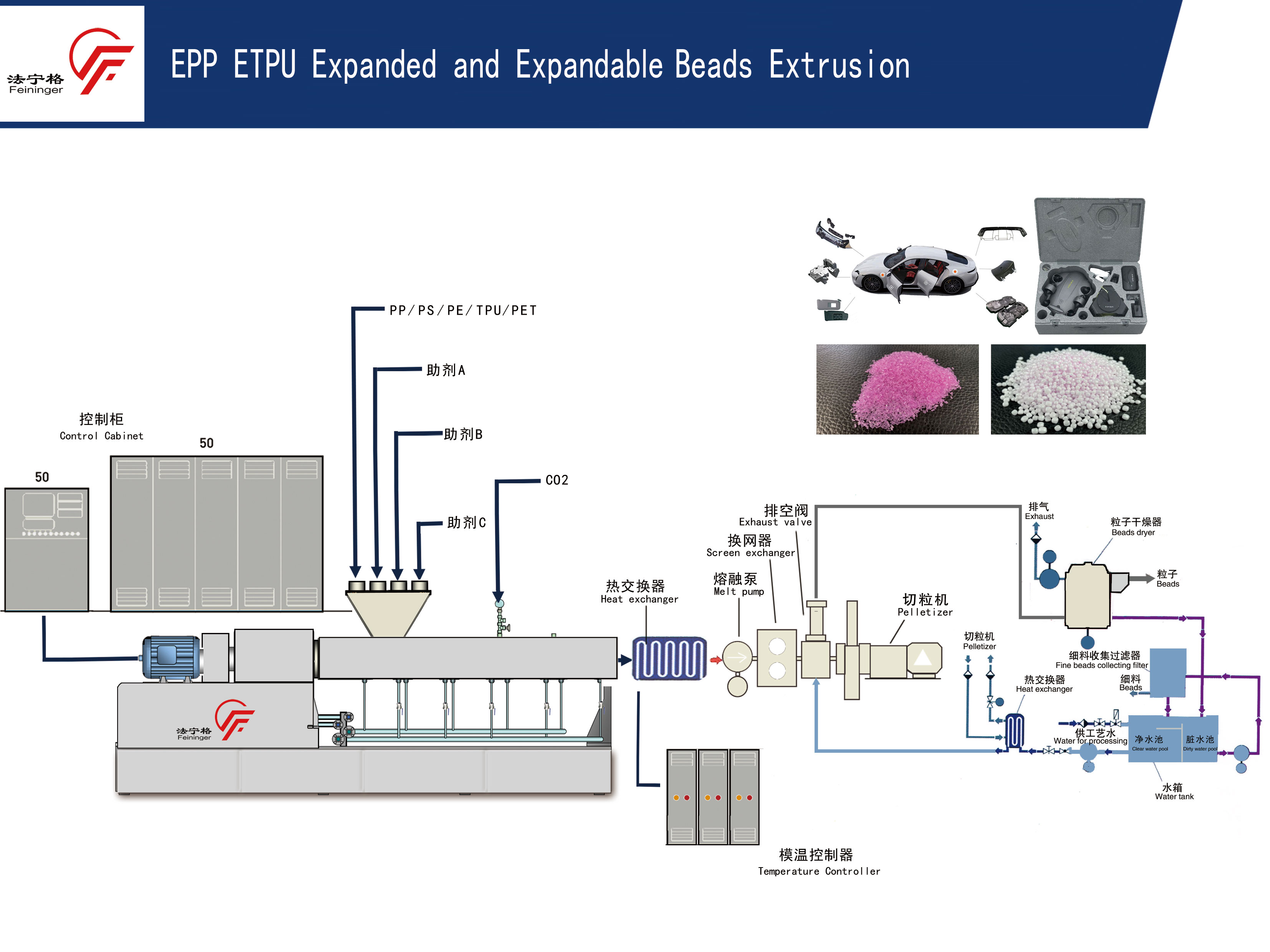

Jul . 2023Feininger has been committed to the research of supercritical CO2 foaming equipment, using CO2 in supercritical state as a physical foaming agent applied to foam extrusion process, can produce microporous plastics with small and dense pores and improved mechanical properties, while achieving energy saving and consumption reduction. Feininger supercritical CO2 extrusion foam ETPU has the advantages of high rate and high resilience.

Advantages of feininger ETPU foamed particles:

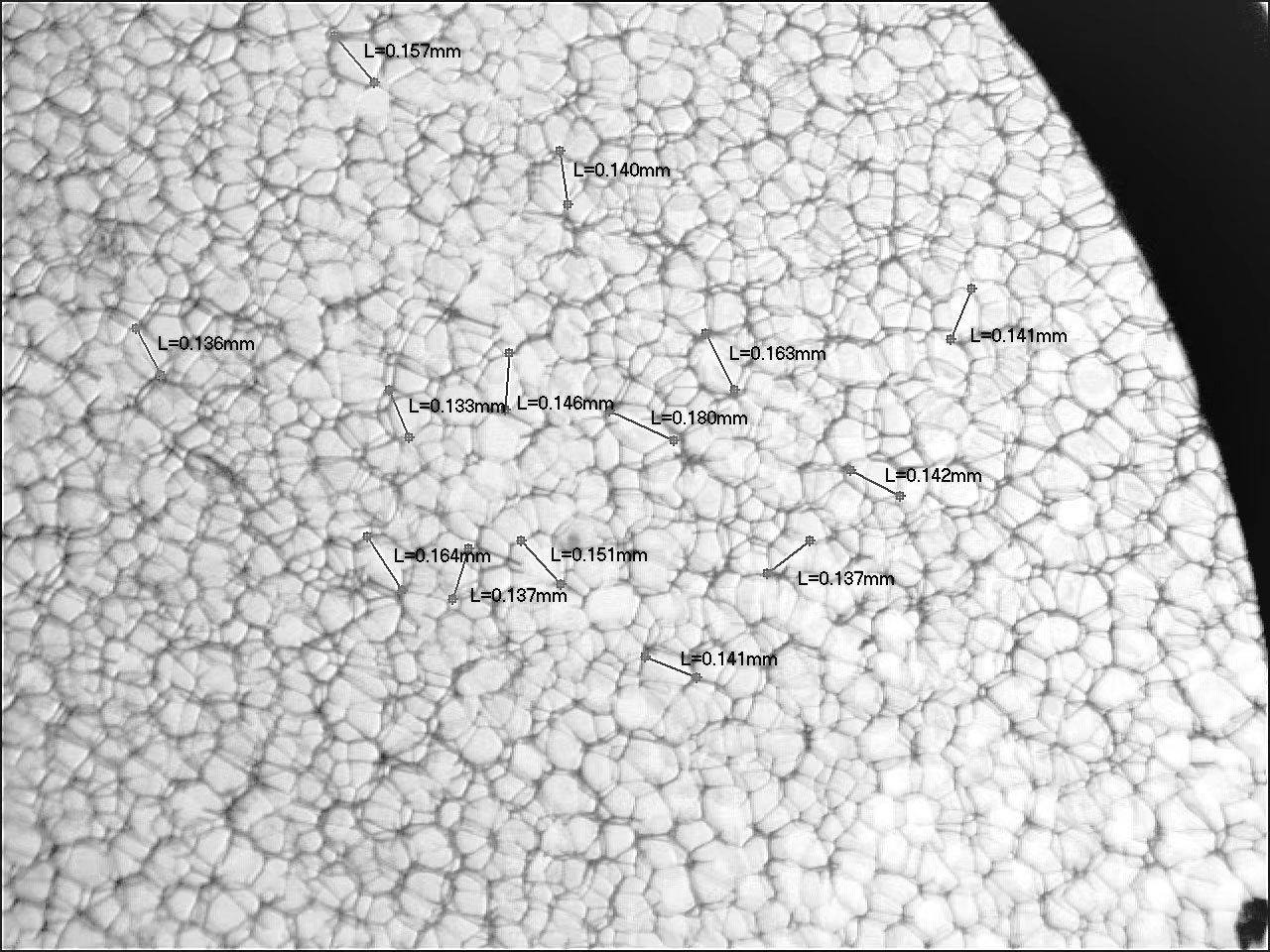

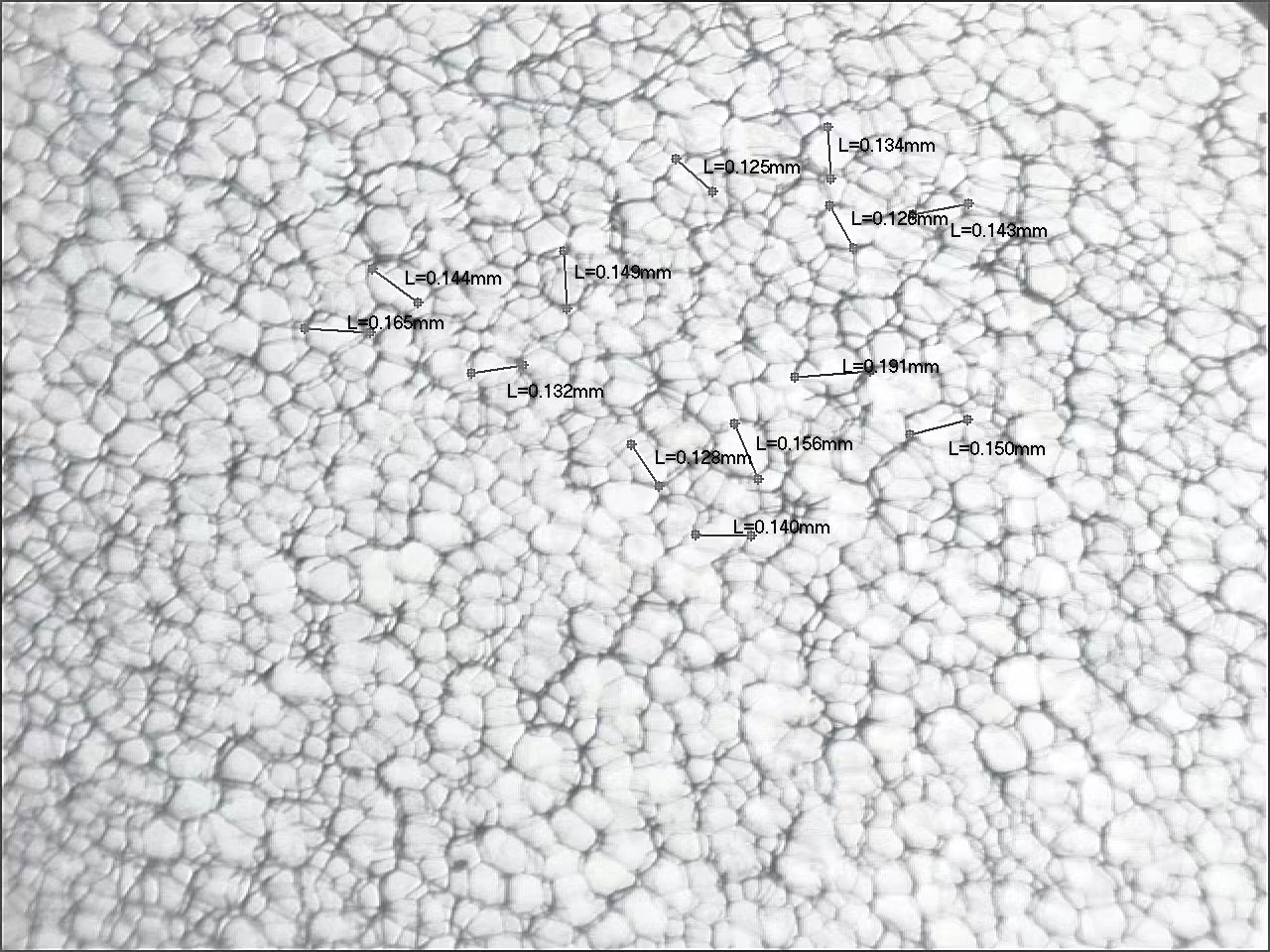

1. feininger ETPU has high foaming rate, bulk density of 100kg/M3, high resilience, resilience of up to 60%, these excellent performance characteristics are determined by the production equipment and production process, so that the cell structure is uniform, and small, and the size of the cell tested under the microscope is less than 200um.

2. In order to make high-quality ETPU, we must first have a precise CO2 foaming agent injection system, a scientific extrusion foaming design concept, and a stable and durable underwater pelleting system to ensure high-quality product quality.

3. Jiangsu Polymer Physics Foaming Engineering Technology Center has a pilot extrusion foaming production line. After countless practices, the raw material formulation process conditions are optimized and the performance of the foaming ETPU material is optimized. In this way, the ETPU with smaller bubble structure can be achieved and the evenly distributed ETPU can achieve the goal of high quality, high rate and high rebound.

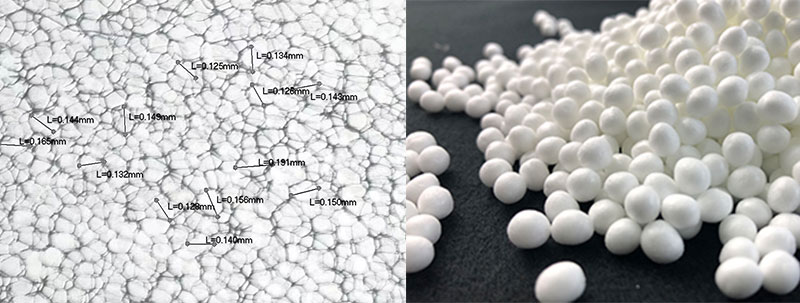

The "ETPU foamed particles produced by supercritical CO2 foaming equipment have ultra-light density, ultra-high resilience, and its production process is green and environmentally friendly without any environmental pollution, and the products are harmless. This material is safe and has no chemical residue. The insole produced by ETPU is non-slip, wear-resistant, cushioned and weather-resistant.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

12 Jul 2023

12 Jul 2023 Feininger and Western University jointly developed a one-step method to produce ETPU "popcorn", which is a boon to the industry

ETPU, or foamed TPU, commonly known as "popcorn", is currently the most elastic foam particle on the market.

12 Jul 2023

12 Jul 2023 Feininger successfully developed a one-step process for the production of epp foam beads

Jiangsu Polymer Physics Foam Engineering Technology Center has successfully developed an innovative process that can economically and efficiently extrude polypropylene (EPP) foam beads using supercritical CO2.