History

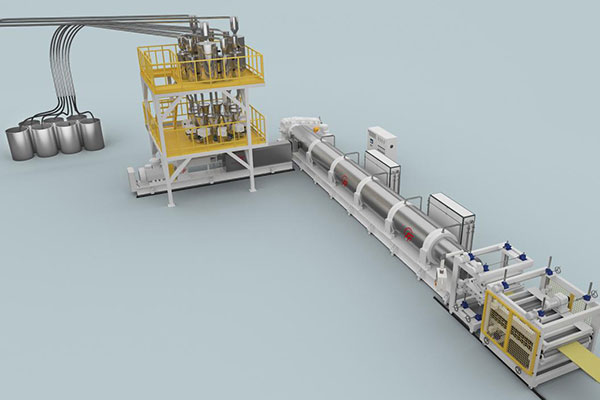

In 2023, EPP/EPS micro-granulation and granulation production line will be successfully put into operation.

Successfully developed an ETP∪ / EPP one-step extrusion production line for foamed beads/sheets.

Successfully developed and put into operation GPl cold storage board production line.

In 2022, Feininger has developed a new supercritical CO2 foaming/new HFOs foaming XPS extrusion board production line.

In 2022, Feininger successfully developed and put into use a PET single-machine flat-double production line, and successfully developed a physical foaming co-extrusion production technology.

In 2021, Feininger successfully developed graphite EPS helmet material, EPO packaging material, EPP material production line.

In 2020, Feininger developed and manufactured a dual-station PET welding machine with a production capacity of 400-500kg/h, a PET low-temperature friction granulator.

In 2019, Feininger successfully delivered a two-stage PET foam sheet production line using CO2 foaming agent 95/250.

In 2018, Feininger was approved as Jiangsu Provincial Polymer Physical Foaming Engineering Technology Center. On the 30th anniversary of China Plastics, Feininger was awarded the Outstanding Contribution Unit of China's Plastics Industry.

In 2017, we successfully researched the extrusion method to produce ETPU using CO2+N2 foaming agent.