Extruded plastic panels are increasingly used in daily life, and it is very common. Extruded plastic board has good performance and is very popular with consumers. Extruded panels are a very common thermal insulation material in the construction industry, with the advantages of saving energy and thermal insulation. It is often used in exterior walls, roofing, roads, railways, refrigerators, refrigerated cars and other fields.

Extruded panel roofing

Extruded panels have a dense surface layer and an inner layer of a closed-cell structure. Its thermal conductivity is much lower than that of foamed polystyrene of the same thickness, so its thermal insulation performance is better than that of foamed polystyrene. In the case of the external wall of the same building, its thickness may be smaller than that of other types of thermal insulation materials. For the thermal insulation of buildings with refrigeration and other special requirements, it can also be used for the characteristics of brick or stone buildings of exterior wall finishing materials, and in high temperature environments, it can still maintain good thermal insulation performance.

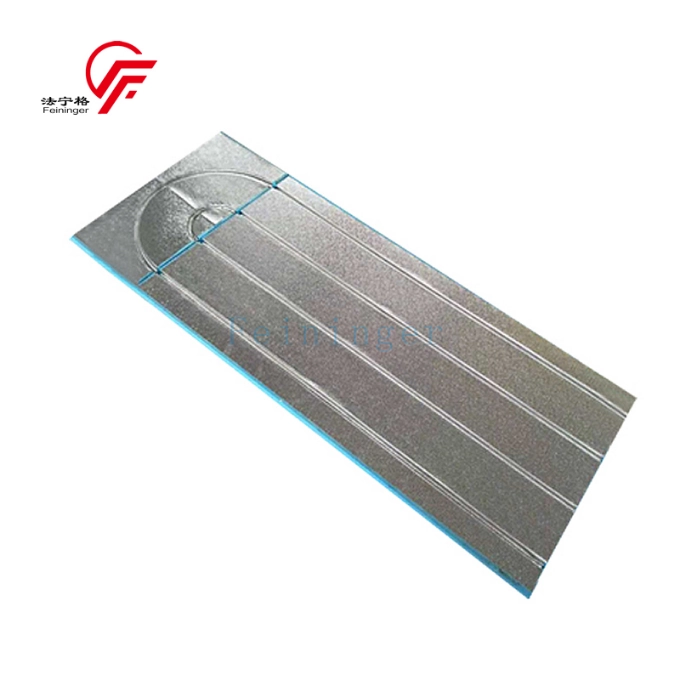

Extruded plastic panels for floor heating

The early floor used EPS foam board, foam pad, glass fiber board, due to the nature of the board itself, its strength is not high, the bearing capacity is low, and the surface brick needs to be strengthened. The factory has to go through a period of maturity and needs to be placed for a period of time before use. If the maintenance time is not enough, the quality of the plate cannot be guaranteed, and the plate shrinks after construction, causing the system to crack.

Extruded plastic panels for steel structures

Due to the large number of fire sources, the traditional steel structure material must use B1 extruded plastic panels. Due to the impact of the fire, it has not yet been applied to steel structures.

Extruded plastic panels for cold storage of refrigerated trucks

XPS has a big advantage in terms of price and performance compared to plutonium.

Extruded sheets for ducts

The 1200 wide extruded plastic board for the duct may replace the traditional duct due to its low price, but its main disadvantage is poor fire resistance.

Nowadays, the performance of extruded plastic board has been very excellent, years of practice has proved that it has been widely used in the construction industry and other industries of thermal insulation, insulation materials.

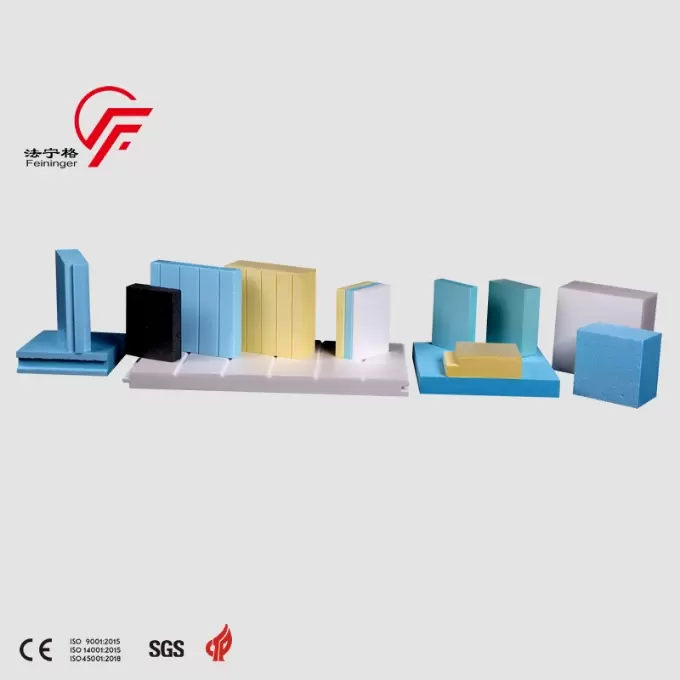

Advantages of Feininger extruded panels

1. Long-term heat preservation

The cold storage runs for a long time and at low temperature, and the temperature difference between the inside and outside of the cold storage is large. Extruded polyethylene foam (XPS) is superior in thermal insulation due to its low thermal conductivity. It has excellent moisture resistance and can maintain good thermal insulation in humid environments.

2. Dimensional stability

Extruded polyethylene foam (XPS) can maintain dimensional stability due to its closed cell rate as high as 99% under severe temperature changes or long-term low temperature, and can ensure that the board is not deformed for a long time.

3. Good compressive performance

Extruded polyethylene foam (XPS) is light in material, high in strength, and its compression resistance can reach 150~700kpa. Whether it is cold storage, road surface, roof, etc., extruded polyethylene foam (XPS) can adapt to long-term environmental loads.

4. Durability

The thermal insulation performance of extruded polyethylene foam (XPS) changes little with time, and it can still have good thermal insulation performance after long-term use, without deformation due to thawing, corrosion and aging, and can ensure long-term stability.

5. Environmental friendly

Extruded polyethylene foam (XPS) has stable chemical properties and will not volatilize harmful substances during use.

Feininger stands as the premier choice for discerning customers seeking high-quality Extruded plastic panels in the Chinese market. As a trusted Extruded plastic panels supplier, our commitment to excellence is evident in every aspect of our business.

We take immense pride in delivering Extruded plastic panels of unparalleled quality, with a keen focus on precision manufacturing and innovative design. Our extrusion process ensures that our panels meet the highest standards, offering durability, exceptional performance, and versatility for various applications.

Our extensive selection of Extruded plastic panels caters to a wide range of industry needs. Whether you require panels for architectural projects, interior decor, industrial applications, or any other purpose, we have the perfect solution for you. With Feininger, you can count on a supplier dedicated to meeting your requirements and exceeding your expectations.

Our team of experts is always ready to assist you in selecting the ideal Extruded plastic panels to suit your specific project. At Feininger, we understand the importance of top-notch customer service and timely delivery, ensuring a seamless experience for our valued clients.

Choose Feininger as your Extruded plastic panels supplier, and experience the difference of high-quality, precision-crafted panels that are built to last. We are committed to elevating your projects with our superior products and unwavering dedication to excellence.

Online Mssage