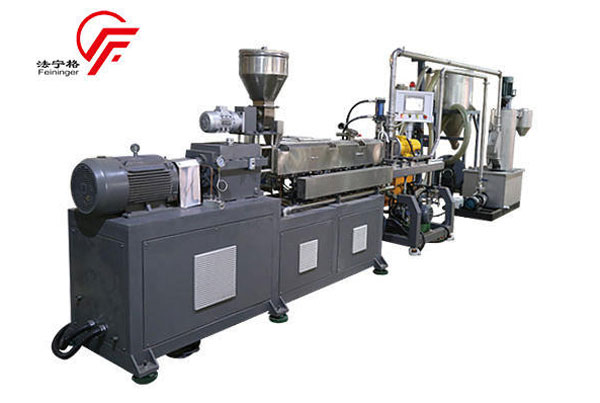

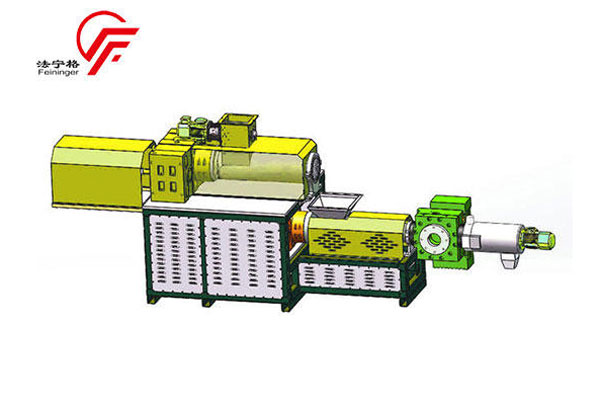

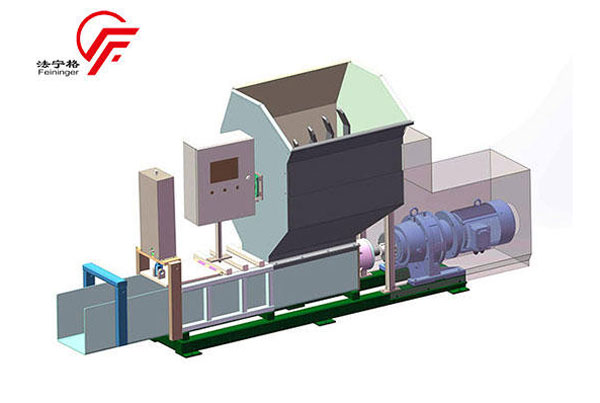

Feininger under water pelletizing system, design science, stable pressure, the temperature control precision, the unique template design ensures the ideal thermal insulation, effectively solves the temperature and water temperature difference is too large for template plastic particles caused by condensation and empty, and prevent the melt in the export of die hole "setting", and because hardly fluctuate process of granulation, the process is very reliable, more effective in reducing heat loss by 95%.

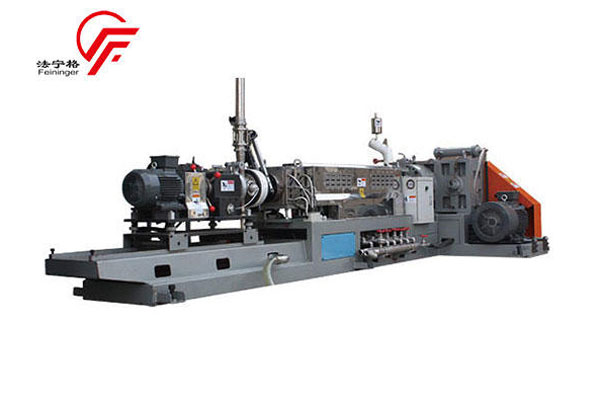

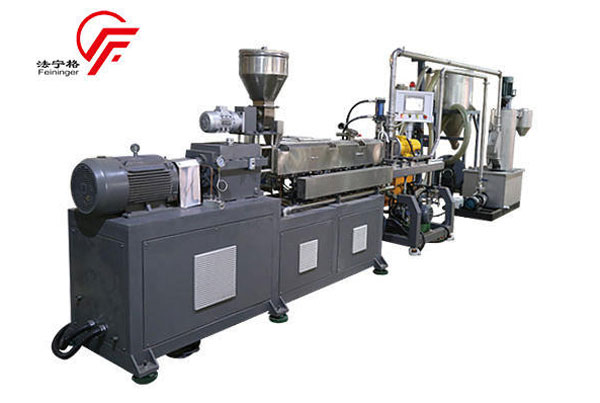

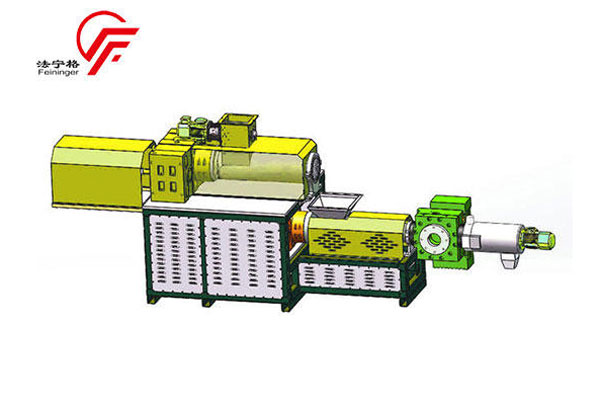

Feininger is rather low density, XPS extrusion moulding, whereas our production line has high compressive strength and reliable quality! Gear box and the scientific design of low power motor! Low energy consumption. As method NingGe in extruded profile production experience, we can provide our clients with free training and technical guidance, avoid detours!

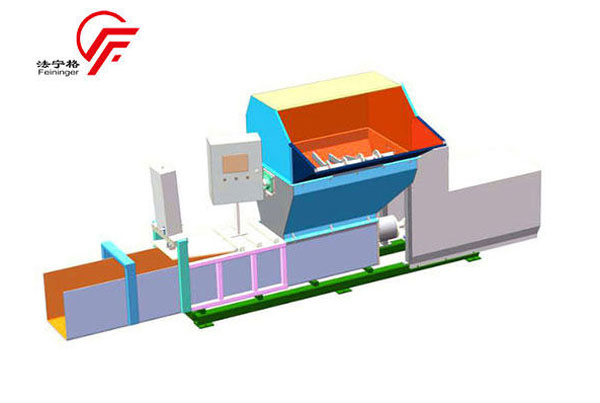

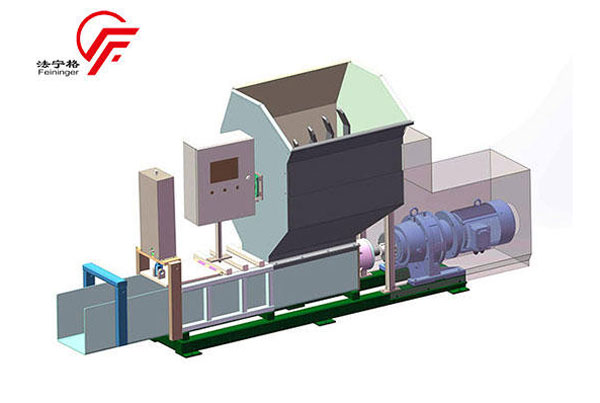

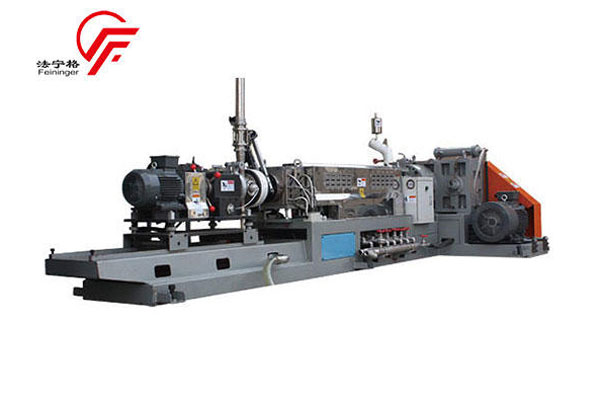

This kind of products is plastic products, its mature processing technology and superior product performance, determines that the market price of products is much lower than the market of various wood materials. Moreover, its installation is simple, convenient, which can greatly reduce the installation of labor costs. The XPS/cornice production line and XPS pipe production line are a better alternative of the same products manufacturing equipment in the existing market.

Recommended Products

Inquiry

For the purchase, use, repair and maintenance of the product, you can contact us here

Solve parts, after-sales and service related problemsgo and have a look~

Send email to Feininger customer service centermarket@feininger.cn

08:30-17:00 from Monday to Saturday