Technology

05

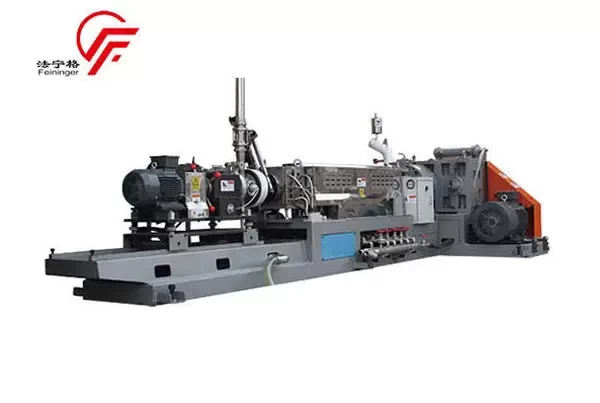

Nov . 2024In the world of material science and manufacturing, innovation is driven by advanced research and testing technologies. One such technological marvel is the Beads Foam Experiment Machine, particularly designed for testing thermoplastic materials like PBAT, PA, and PET. This machine has proven to be a pivotal tool for universities, research institutions, and enterprises, bridging the gap between laboratory research and industrial application.

The Beads Foam Experiment Machine is equipped with a range of features that enhance its versatility and efficiency:

Weightless Scale Loading System: This innovative system allows for precise measurements of materials, ensuring accurate experimentation and consistent results.

Foaming Agent Filling System: The machine includes a dedicated system for filling foaming agents, enabling the creation of various foam densities and structures tailored to specific applications.

Screw Extruder: Comprising both first and second stages, the screw extruder plays a critical role in mixing and processing thermoplastics, ensuring a uniform blend before foaming.

Melt Pump/Static Mixer: This component ensures that the molten polymer is processed evenly, facilitating a smooth transition from the extruder to the mold.

Mold Capabilities: The machine can produce sheets and various foam shapes, allowing researchers to experiment with different designs and applications.

Traction Cutting: This feature allows for precise cutting of the foamed material, ensuring that samples meet required dimensions for further testing or application.

The Beads Foam Experiment Machine is not only crucial for academic research but also plays a significant role in various industrial applications:

Researchers utilize this machine to develop new foam materials that meet specific performance criteria. The ability to test different formulations of PBAT, PA, and PET helps in creating materials with desirable properties, such as improved strength, flexibility, or thermal resistance.

Before full-scale production, companies can use the Beads Foam Experiment Machine to conduct pilot tests. This allows them to evaluate the feasibility of their foam formulations and make necessary adjustments without the high costs associated with large-scale manufacturing.

In manufacturing environments, maintaining consistent quality is essential. The Beads Foam Experiment Machine allows for ongoing testing of foam products, ensuring that they meet industry standards and customer expectations.

Different industries, from automotive to packaging, have unique requirements for foam materials. The flexibility of the Beads Foam Experiment Machine enables manufacturers to create customized foams tailored to specific applications, whether for cushioning, insulation, or structural purposes.

Academic institutions leverage this machine to conduct fundamental research into foam properties and behaviors. This research not only contributes to academic knowledge but also fuels innovation in the industry, leading to new products and technologies.

The Beads Foam Experiment Machine stands at the forefront of material science, providing the tools necessary for transitioning from lab experiments to industrial applications. With its advanced features and versatility, it enhances the development and testing of thermoplastic materials, ultimately driving innovation across various industries. As companies continue to seek ways to improve their products and processes, the importance of such laboratory equipment cannot be overstated.

For manufacturers and researchers alike, investing in a Beads Foam Experiment Machine could mean the difference between stagnation and success in the ever-evolving world of material technology.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

24 Jul 2024

24 Jul 2024 Choosing the Right TPU Underwater Pelletizer: Key Considerations and Tips

Thermoplastic polyurethane (TPU) underwater pelletizers are essential in the polymer processing industry, especially for producing high-quality TPU pellets.

10 Nov 2023

10 Nov 2023 Advantages of carbon dioxide foam extrusion board production line

Because of its excellent thermal insulation, high compressive resistance, low water absorption, lightweight and other characteristics, it is widely used in building external wall insulation, cold storage, water conservancy engineering, central air conditioning pipeline, cold highway, airport runway, high-speed railway subgrade and so on.

28 May 2024

28 May 2024 China Feininger to Participate in IndoBuildTech Expo 2024

China Feininger is excited to announce its participation in the upcoming IndoBuildTech Expo 2024, the largest building material, architecture, and interior exhibition in Indonesia.