Technology

15

Aug . 2024In the world of composite materials, the demand for lightweight, durable, and environmentally friendly solutions is growing rapidly. PET foam core production lines are at the forefront of this transformation, offering innovative and sustainable materials that meet the needs of various industries. Companies like Feininger are leading the way by providing advanced PET foam core production technologies that are revolutionizing how composite materials are manufactured and utilized.

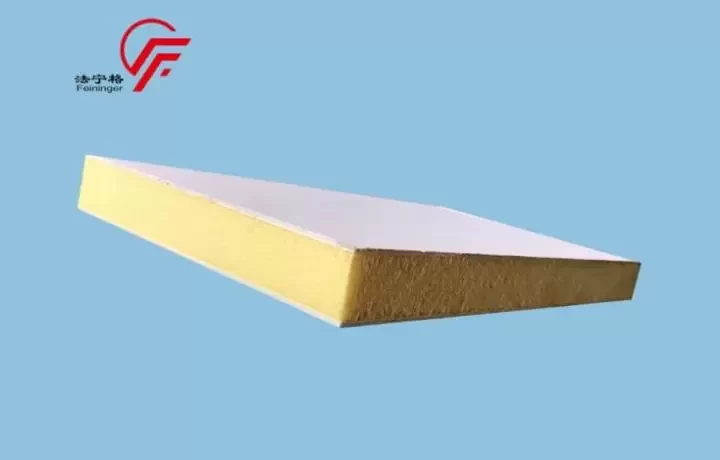

Polyethylene terephthalate (PET) foam cores are emerging as a preferred choice in composite material applications due to their excellent properties. PET foam is derived from polyester resin and is renowned for its mechanical strength, thermal insulation, and environmental benefits. The development of PET foam cores is driven by advanced foaming technology, which utilizes carbon dioxide as a foaming agent instead of traditional fluorine-based agents. This shift not only reduces production costs but also enhances the environmental profile of the material.

Environmental Sustainability

Eco-Friendly Production: By using CO2 as a foaming agent, PET foam production lines eliminate the emission of harmful greenhouse gases. This sustainable approach significantly reduces the environmental impact compared to traditional methods.

Recyclability: PET foam boards are fully recyclable, contributing to a circular economy. This recyclability makes them an attractive choice for industries seeking to minimize waste and reduce their carbon footprint.

Exceptional Mechanical Properties

Shear Resistance: PET foam cores provide excellent shear strength, making them suitable for demanding structural applications where stability and durability are critical.

Thermal Insulation: With superior thermal insulation properties, PET foam cores are ideal for use in building insulation and other applications requiring temperature regulation.

Heat Resistance: PET foam maintains its structural integrity at high temperatures, making it suitable for applications in harsh environments.

Versatility and Performance

Wide Range of Applications: PET foam cores are used in various fields, including building thermal insulation, sandwich structure core materials, sports equipment, fan blades, ships, and aerospace components.

Mechanical Strength: As a thermoplastic engineering material, PET offers excellent mechanical strength, electrical insulation, and resistance to chemicals, creep, fatigue, and friction.

Feininger is a leading provider of PET sheet extrusion lines, offering cutting-edge solutions that ensure high performance, low energy consumption, and long-term durability. Their production lines are modular and customizable, providing companies with the flexibility to adapt to specific production needs and enhance productivity.

High Performance: Designed to deliver consistent and high-quality output, ensuring that PET foam cores meet stringent industry standards.

Energy Efficiency: By minimizing energy consumption, Feininger production lines help reduce operational costs while supporting sustainable manufacturing practices.

Customization: The modular design of Feininger’s production lines allows for tailored solutions that address the unique requirements of different industries.

Stable Performance: Feininger’s machines are engineered for long-term reliability, providing stable performance and reducing maintenance needs.

The versatility and environmental benefits of PET foam cores make them an attractive option across various industries:

Construction: PET foam cores are widely used as insulation materials, enhancing energy efficiency in buildings and reducing overall energy consumption.

Transportation: In the automotive and aerospace sectors, PET foam cores contribute to weight reduction, improving fuel efficiency and performance.

Sports Equipment: PET foam is used in manufacturing lightweight and durable sports gear, offering enhanced performance and comfort.

Marine Applications: The resistance to moisture and chemicals makes PET foam cores ideal for use in boats and other marine structures.

As industries continue to prioritize sustainability and performance, PET foam core production lines are playing a pivotal role in shaping the future of composite materials. With their exceptional properties and environmental benefits, PET foam cores are poised to become a cornerstone of modern manufacturing.

Feininger, a leader in PET foam core technology, is at the forefront of this transformation, offering innovative solutions that drive efficiency and sustainability. By investing in advanced PET foam core production lines, companies can unlock new opportunities and stay ahead in a rapidly evolving market.

For more information on Feininger’s PET foam core production solutions, please visit our website or contact our team of experts.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

07 Feb 2025

07 Feb 2025 Top 5 Reasons to Choose XPS with PVC Sandwich Board for Your Construction Projects

When it comes to modern construction materials, the XPS with PVC sandwich panel has emerged as a top choice for builders and contractors alike. This composite material, which consists of two PVC layers with XPS (extruded polystyrene) foam in between, offers exceptional benefits that make it ideal for a wide range of construction projects.

21 Jun 2024

21 Jun 2024 The Future of Building Insulation: Trends and Innovations in XPS Foam Board with Aluminum Foil

As we move further into the 21st century, the demand for more efficient, sustainable building materials is on the rise. One of the standout products in this evolution is the XPS (Extruded Polystyrene) Foam Board with Aluminum Foil.

09 Nov 2023

09 Nov 2023 Feininger high-strength Cold Storage Extruded Plastic Panels

In addition to important factors such as thermal efficiency and moisture resistance, the insulation of extruded panels in refrigerated cold storage needs to have sufficient compressive strength characteristics.