Technology

16

Apr . 2025In the world of foam production, precision and consistency are key to achieving high-quality products. Whether it's for packaging, insulation, or construction applications, Expanded Polystyrene (EPS) foam plays a crucial role in numerous industries. As demand for EPS foam grows, manufacturers are seeking ways to streamline production while maintaining product quality and reducing energy consumption. Feininger has answered this need with its advanced EPS Beads Foam Extrusion Line, a cutting-edge solution designed to optimize production efficiency and deliver exceptional results.

Feininger's Advanced Graphite EPS Production Line: Innovation at Its Best

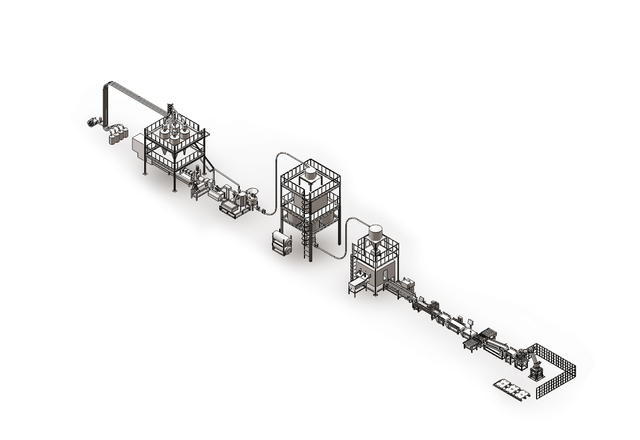

Feininger's Graphite EPS production line is built on years of research and development, introducing a scientific approach to extrusion equipment design. The company's innovative parallel twin-screw design ensures that the production process runs smoothly, reducing the chances of blockages and improving the overall quality of the finished products. The extruder design has been meticulously crafted to optimize the extrusion process, providing uniform temperature control throughout the entire system.

The heat exchanger in Feininger's EPS production line plays a critical role in ensuring uniform temperature across the system. By maintaining an even temperature, the process prevents the extrusion holes from becoming blocked, which can otherwise disrupt production and lead to inferior product quality. As a result, manufacturers benefit from higher productivity and more consistent foam beads, enhancing the overall quality of their products.

High Performance, Low Energy Consumption, and Durability

Feininger's EPS Beads Foam Extrusion Line is designed for maximum performance, low energy consumption, and durability. This advanced extrusion system ensures that production lines are not only efficient but also long-lasting, making it an ideal choice for companies in the plastics and foam industry. Each line is modular, allowing for complete customization according to the specific needs of the manufacturer.

The versatility of Feininger's extruders makes them suitable for a wide range of applications, including the production of graphite EPS foam, which offers improved thermal insulation properties. The system's energy-efficient design reduces operational costs, providing manufacturers with a cost-effective solution to meet increasing demand for high-quality foam products.

Precision Temperature and Water Pressure Control for Superior Foam Quality

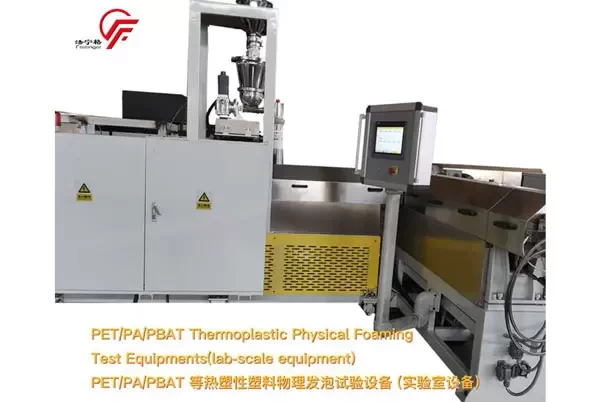

One of the standout features of Feininger's EPS Beads Foam Extrusion Line is its ability to precisely control water temperature and water pressure during the extrusion process. This is crucial in the production of thermoplastic foam particles, which are molded through a water-based extrusion process that requires high water pressure for optimal results.

Feininger’s system ensures that water pressure is maintained at the ideal level, preventing blockages in the discharge holes and avoiding foam buildup in the early stages of production. This level of control guarantees that foam particles are produced to the highest quality, with uniform size and shape. The centrifugal drying and vibration cooling beads are also designed for efficiency, with a bottom-up vibration system that ensures effective cooling and drying of the foam beads.

A Cost-Effective and Efficient Solution for Manufacturers

Feininger's Graphite EPS production line is not just about advanced technology; it’s also about practicality and cost-effectiveness. By utilizing high-quality materials and a scientific approach to equipment design, Feininger has created an extrusion line that minimizes downtime, reduces maintenance costs, and improves overall productivity.

The system's modular nature means that each line can be tailored to meet the specific needs of the customer. Whether a manufacturer is looking to produce graphite EPS for enhanced insulation or traditional EPS foam for packaging, Feininger provides a solution that ensures maximum output and top-notch product quality.

Furthermore, Feininger offers free technical training for customers, ensuring that they can get the most out of their equipment without the need for expensive troubleshooting or external support. This added service helps clients optimize their production processes and avoid unnecessary delays.

The Benefits of Choosing Feininger's EPS Beads Foam Extrusion Line

High-Quality Foam Production: Feininger's advanced design ensures uniform foam beads with consistent size and shape.

Energy Efficiency: The extruder's low energy consumption design reduces operational costs while maintaining high production efficiency.

Durability and Reliability: The use of high-quality materials and innovative design guarantees long-lasting performance with minimal maintenance.

Modular Design: Feininger's extrusion lines are customizable, allowing manufacturers to tailor the system to their specific needs.

Efficient Cooling and Drying: The vibration cooling beads system and centrifugal drying provide effective cooling and faster production cycles.

Reduced Downtime: The uniform temperature and pressure control help avoid production delays and ensure continuous operation.

Technical Support: Feininger offers free technical training to help customers maximize their equipment's performance.

Conclusion

Feininger's EPS Beads Foam Extrusion Line represents the perfect fusion of innovation, efficiency, and high-quality output. By adopting a scientific approach to extruder design and offering customizable options, Feininger has developed an extrusion system that maximizes productivity, reduces energy consumption, and ensures the highest quality foam products. With Feininger's years of experience in graphite EPS production and a focus on long-term performance, manufacturers can trust that their production lines will deliver consistent results, faster production times, and a significant return on investment.

For more information or to explore customization options for your foam production line, reach out to Feininger today and discover how our EPS Beads Foam Extrusion Line can streamline your production process and improve your bottom line.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

05 Jul 2024

05 Jul 2024 The Step-by-Step Process of PET Foam Sheet Production

The production of PET foam sheets is a sophisticated process that involves advanced technology and precision engineering. PET foam sheets, known for their lightweight, durable, and versatile nature, are used in various industries, including automotive, construction, and packaging.

08 Dec 2023

08 Dec 2023 How to choose extruded board manufacturers?

There are a variety of thermal insulation products in the building thermal insulation material market, and extruded plastic boards are favored by consumers because of their health and environmental protection and excellent physical and chemical properties.

21 Aug 2024

21 Aug 2024 Innovative Features to Look for in a Foam Sheet Laboratory Machine

In the world of materials science and product development, foam sheet laboratory machines play a critical role in research, testing, and small-scale production.