Technology

08

Jul . 2024In the competitive landscape of the plastics industry, adopting advanced production technologies can significantly enhance operational efficiency and product quality. One such innovation is the PET foam sheet production line, which offers numerous benefits for businesses. Here, we delve into the top five advantages of incorporating a PET foam sheet production line, particularly highlighting the Feininger PET sheet extrusion line, renowned for its high performance, low energy consumption, and durability.

The Feininger PET sheet extrusion line is engineered for high performance, ensuring that businesses can achieve optimal output levels. These production lines are designed to handle large volumes of raw materials efficiently, converting them into high-quality PET foam sheets. This increased productivity allows businesses to meet high demand without compromising on quality.

One of the standout features of Feininger's production lines is their modular design. This flexibility allows companies to customize every detail according to their specific needs, ensuring that the production line is perfectly suited to their operational requirements. This customization leads to improved production efficiency and product consistency.

Feininger's PET sheet extrusion lines are built with energy efficiency in mind. The advanced technology used in these machines ensures that energy consumption is minimized without affecting performance. This energy efficiency translates into lower operational costs, making the production process more sustainable and cost-effective in the long run.

By reducing energy consumption, businesses can significantly lower their production costs. This cost efficiency is crucial in maintaining competitive pricing and improving profit margins. Feininger’s focus on energy-efficient design helps businesses achieve these savings while maintaining high production standards.

Feininger’s PET sheet extrusion lines are known for their durability. Constructed with high-quality materials and advanced engineering techniques, these machines are built to last. This robustness ensures that businesses can rely on their production lines for long-term, stable performance, reducing the need for frequent repairs or replacements.

Durability is complemented by the stable performance of Feininger’s production lines. With continuous improvements and rigorous testing, these machines offer reliable operation over extended periods. This stability is essential for maintaining consistent production quality and meeting delivery schedules.

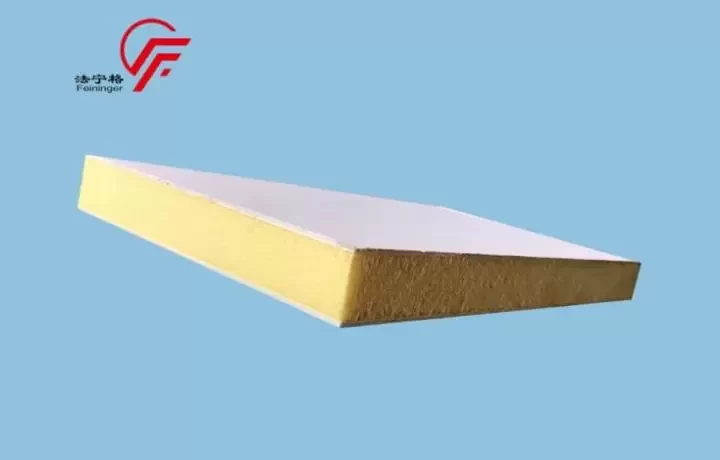

PET foam sheets have a wide range of applications, from automotive and construction to packaging and insulation. Feininger’s PET sheet extrusion lines are designed to produce foam sheets that meet diverse industry requirements. This versatility allows businesses to explore multiple market opportunities and expand their product offerings.

The ability to customize the production line means that businesses can produce PET foam sheets with varying specifications, catering to specific customer needs. This adaptability is crucial for businesses looking to differentiate themselves in the market by offering unique and tailored products.

Feininger is committed to continuous research and development, integrating the latest technological advancements into their PET sheet extrusion lines. This innovation ensures that businesses using Feininger’s production lines remain at the forefront of the industry, benefiting from the most advanced and efficient production techniques available.

With Feininger’s ongoing improvements in performance levels, businesses can achieve higher productivity while reducing costs. The integration of cutting-edge technology and innovative solutions helps streamline the production process, making it more efficient and cost-effective.

Incorporating a PET foam sheet production line into your business offers numerous benefits, from enhanced productivity and energy efficiency to durability and versatility. The Feininger PET sheet extrusion line exemplifies these advantages, providing high performance, customizable solutions tailored to the needs of the plastics industry. With its focus on innovation and continuous improvement, Feininger ensures that businesses can achieve long-term success and maintain a competitive edge in the market. Investing in a Feininger PET sheet extrusion line is a strategic decision that can drive growth, efficiency, and profitability for your business.

>Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

07 Feb 2025

07 Feb 2025 Top 5 Reasons to Choose XPS with PVC Sandwich Board for Your Construction Projects

When it comes to modern construction materials, the XPS with PVC sandwich panel has emerged as a top choice for builders and contractors alike. This composite material, which consists of two PVC layers with XPS (extruded polystyrene) foam in between, offers exceptional benefits that make it ideal for a wide range of construction projects.

28 May 2024

28 May 2024 China Feininger to Participate in IndoBuildTech Expo 2024

China Feininger is excited to announce its participation in the upcoming IndoBuildTech Expo 2024, the largest building material, architecture, and interior exhibition in Indonesia.

18 Sep 2024

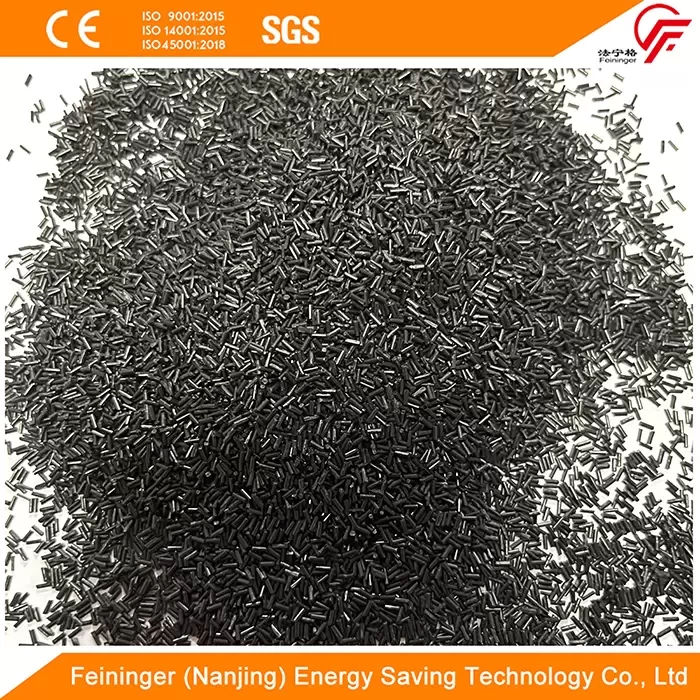

18 Sep 2024 Maximizing Thermal Performance with EPS Graphite Particle Technology

In today's fast-paced world, effective thermal management is crucial for a wide range of applications, from construction to electronics. One of the most innovative solutions making waves in the industry is the use of EPS (Expanded Polystyrene) Graphite Particle technology.