Technology

27

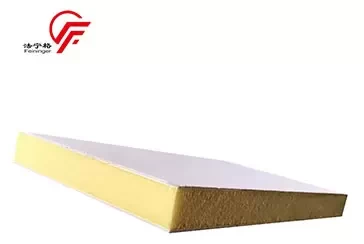

Nov . 2024In cold storage construction, the choice of insulation material is crucial. The performance and longevity of the storage facility depend on the insulation's ability to maintain excellent thermal resistance and withstand high humidity environments over the long term. China Feininger, a leader in advanced foam technology, offers XPS extruded boards as a top-tier solution for cold storage insulation. This blog explores the unique features and advantages of XPS extruded boards and why they are the ideal choice for cold storage facilities.

Cold storage facilities require materials with persistent thermal conductivity to maintain low temperatures efficiently. Feininger’s XPS extruded board is designed with ultra-low thermal conductivity, ensuring consistent insulation performance over its lifespan. This makes it highly energy-efficient, helping businesses reduce operational costs while maintaining the ideal storage environment.

The closed-cell structure of XPS boards enhances their insulating properties, ensuring that temperature fluctuations are minimized even in extreme conditions. This stability in thermal resistance makes them a standout choice for industries relying on precise temperature control, such as food storage, pharmaceuticals, and logistics.

High humidity levels, often exceeding 80% in cold storage environments, can severely impact the effectiveness of insulation materials. Feininger’s XPS boards boast exceptional moisture resistance, with very low water vapor permeability and water absorption rates.

This moisture resistance prevents internal condensation within walls, a common issue in high-humidity environments that can degrade insulation materials. XPS extruded boards maintain their thermal resistance and structural integrity, even under prolonged exposure to moisture, ensuring reliable performance throughout their lifecycle.

Durability is a critical factor in selecting insulation for cold storage. XPS extruded boards offer:

Feininger XPS extruded boards are easy to process and handle during installation. Their low temperature deformation coefficient ensures dimensional stability, allowing for precise cutting and secure fixing at the site. The ease of segmentation processing minimizes construction time and reduces installation costs.

Additionally, XPS boards are non-corrosive, non-rotting, and resistant to most chemicals, making them a low-maintenance option that ensures long-term reliability.

China Feininger has established itself as a trusted manufacturer of high-performance foam products, including XPS extruded boards. With a focus on innovation, durability, and customer satisfaction, Feininger provides free technical guidance and advanced production expertise to ensure that their XPS boards deliver unmatched value in cold storage applications.

Feininger XPS extruded boards are the ultimate choice for cold storage insulation, offering unparalleled thermal insulation, moisture resistance, and durability. Their ability to maintain performance in high-humidity environments makes them an indispensable material for cold storage facilities worldwide.

By choosing Feininger XPS extruded boards, businesses can ensure long-lasting insulation performance, reduced energy costs, and optimal storage conditions. For more information or to explore how Feininger can support your cold storage project, contact China Feininger today.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

11 Oct 2024

11 Oct 2024 Why ETPU Foam Particles Are the Go-To Solution for Shock Absorption

In the world of materials science, ETPU (Expanded Thermoplastic Polyurethane) foam particles have earned their reputation as "magic particles." Recognized for their exceptional shock absorption properties, ETPU foam particles are transforming various industries, including sporting goods, leisure and fitness, and furniture.

24 Jan 2024

24 Jan 2024 Streamline Your Cornice Production with the XPS Cornice Production Line

Are you tired of the traditional and time-consuming methods of cornice production? Do you dream of streamlining your process, increasing efficiency, and boosting productivity? Well, we have some exciting news for you!

20 Nov 2023

20 Nov 2023 The manufacturing process of extruded panels

Although the production process of XPS type foam board is not complicated, we must pay close attention to all links in the process to ensure that the extruded board produced meets national and industry standards