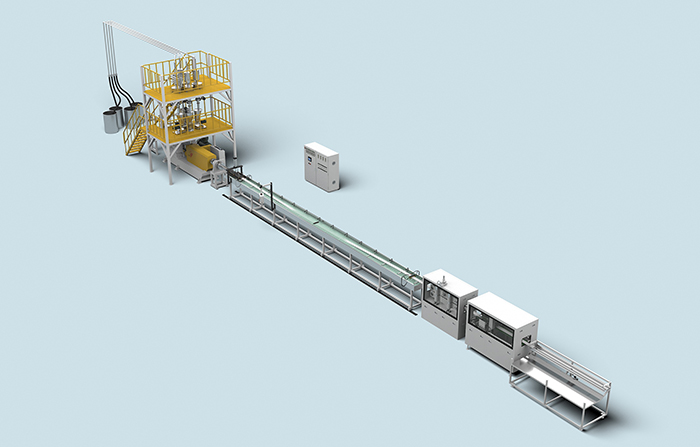

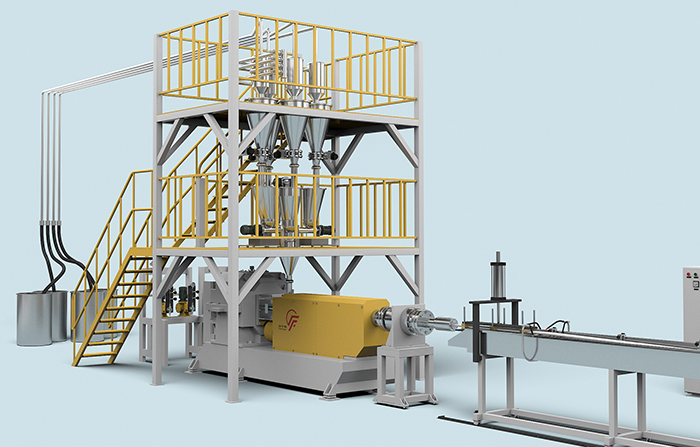

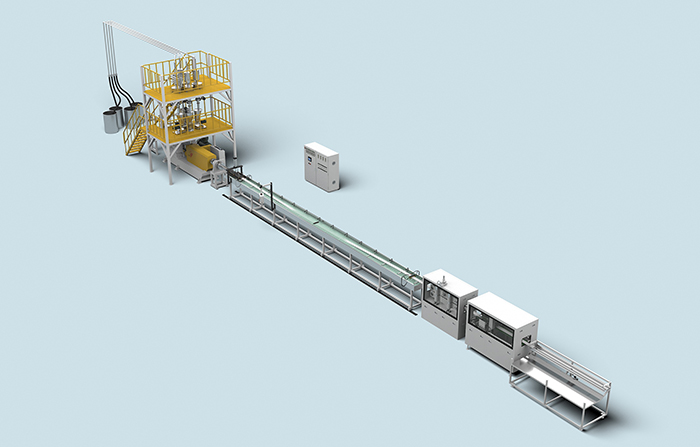

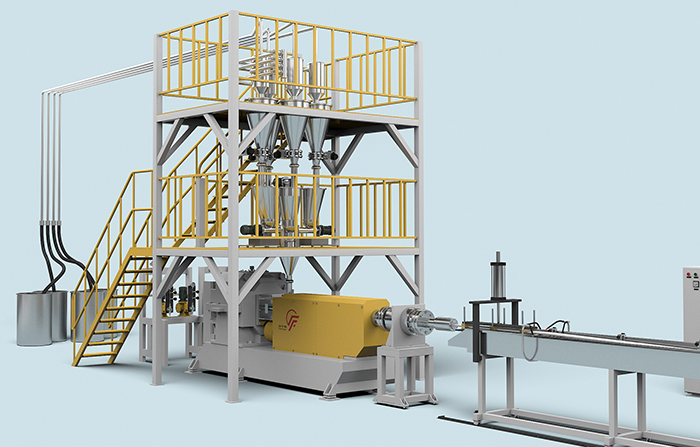

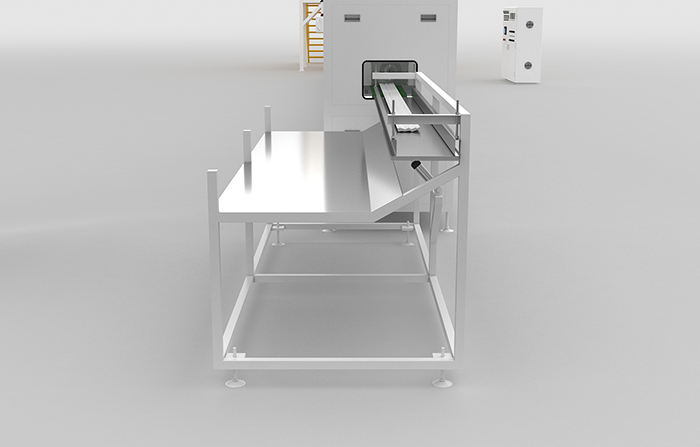

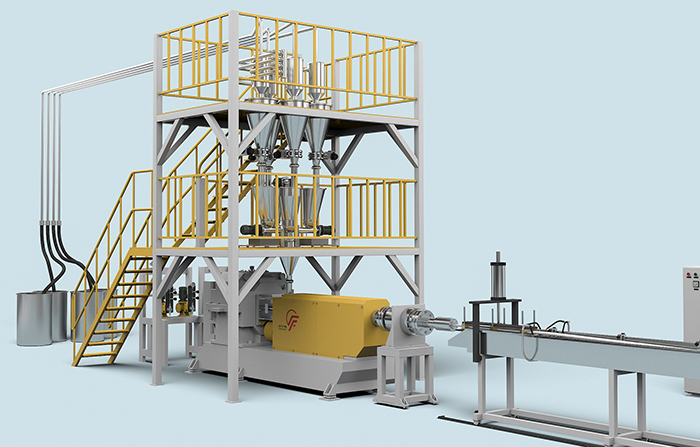

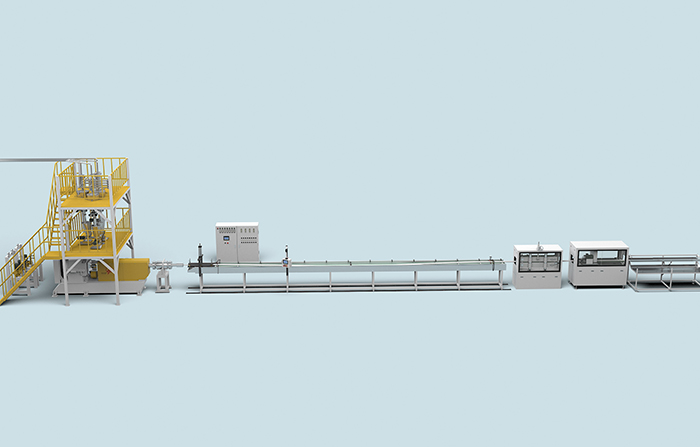

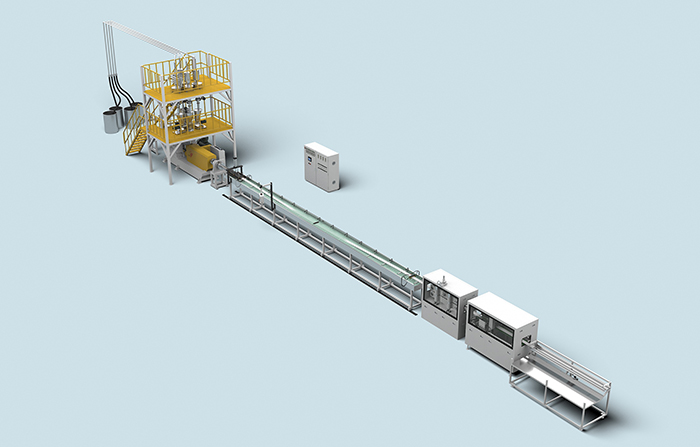

- Feininger XPS cornice production line, the feed system of scientific configuration, the temperature control of the foaming agent injection systems and heat exchanger, 100% co2 foam!

- Feininger is rather low density, XPS extrusion moulding, whereas our production line has high compressive strength and reliable quality!

- Gear box and the scientific design of low power motor! Low energy consumption. As method NingGe in extruded profile production experience, we can provide our clients with free training and technical guidance, avoid detours!

Feininger is rather low density, XPS extrusion moulding, whereas our production line has high compressive strength and reliable quality! Gear box and the scientific design of low power motor! Low energy consumption. As method NingGe in extruded profile production experience, we can provide our clients with free training and technical guidance, avoid detours!

It is suitable for woodworking nailing, spray painting, home decoration and other pneumatic operations

1100W

125mm

1/8pcs

Model | Extruder Type | Length/ Diameter | Foam output (kg/hr) | Blowing Agent (Gas) | Thickness of Profile (mm) | Width of Profile (mm) |

CS-75T | TE75 | 22-26 | 20-80 | 100% CO2 | 5-15mm | 25-150mm |

CS-85T | TE85 | 22-24 | 40-150 | 8-20mm | 40-220mm | |

CS-95T | TE95 | 22-24 | 60-250 | 8-20mm | 65-300mm |

Recommended Products

Inquiry

For the purchase, use, repair and maintenance of the product, you can contact us here

Solve parts, after-sales and service related problemsgo and have a look~

Send email to Feininger customer service centermarket@feininger.cn

08:30-17:00 from Monday to Saturday