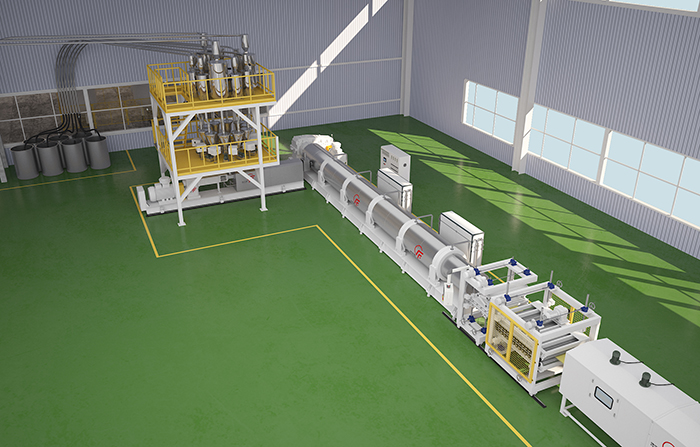

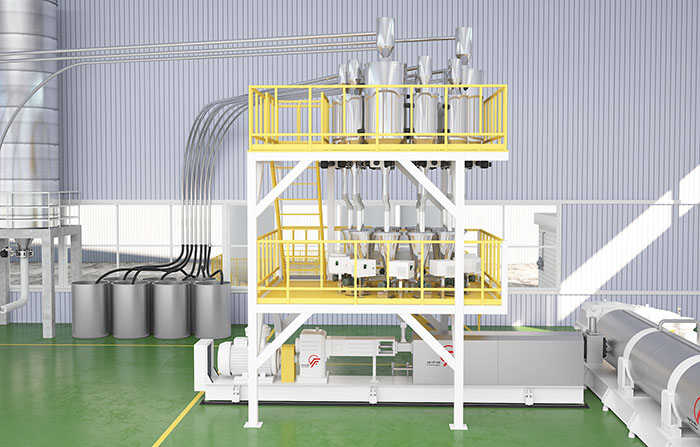

- Feininger XPS foam board production line with the characteristics of high output, low energy consumption, high efficiency.

- Free technical guidance, our advanced production technology and rich experience to bring you wealth!

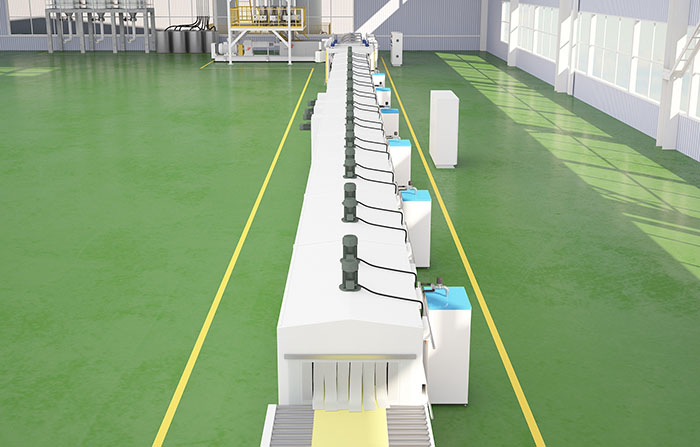

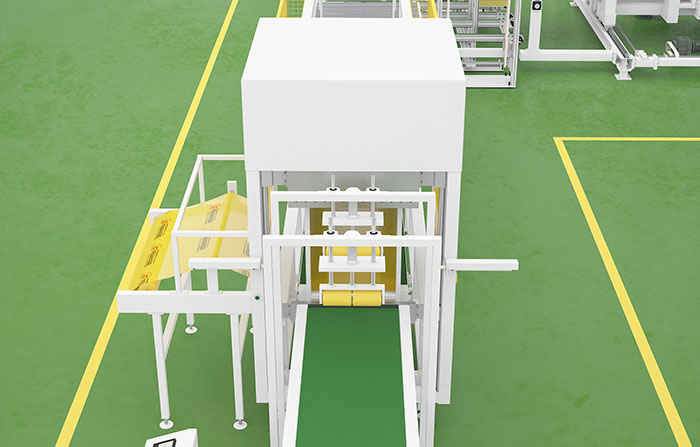

- Spiral structure and production line transmission of scientific design, automatic feeding system, makes the workshop clean.High torque gear transmission, low power consumption.

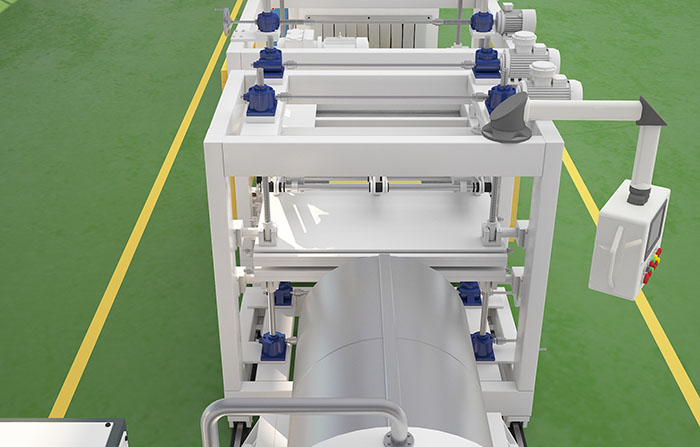

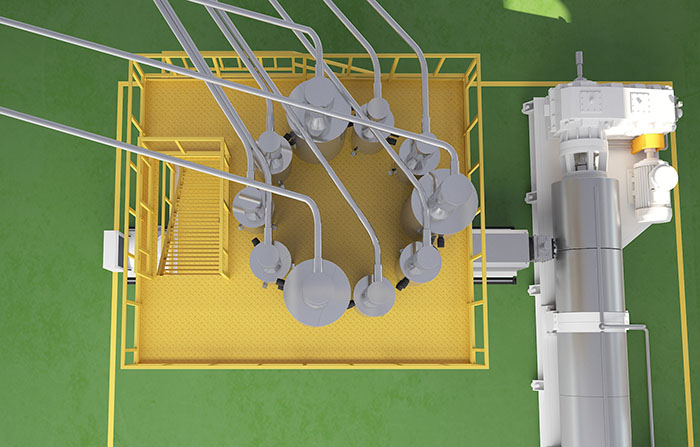

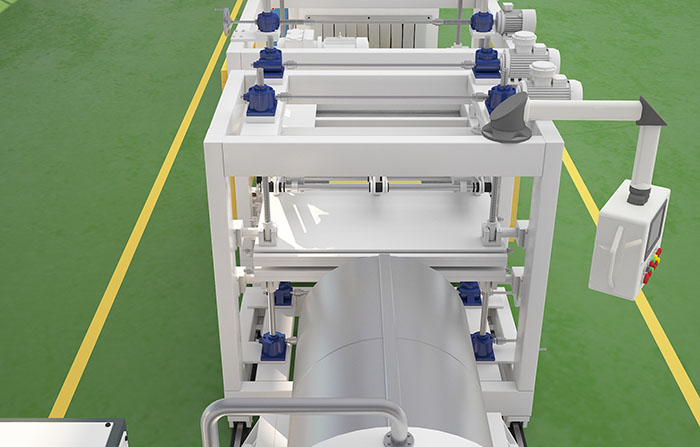

- Screw structure effectively, make the raw materials mixing, no dead Angle. The cooling of the professional process design, realized the full uniform cooling, high efficiency.

Feininger XPS foam board production line with the characteristics of high output, low energy consumption, high efficiency. Free technical guidance, our advanced production technology and rich experience to bring you wealth!

Spiral structure and production line transmission of scientific design, automatic feeding system, makes the workshop clean. High torque gear transmission, low power consumption.

Screw structure effectively, make the raw materials mixing, no dead Angle. The cooling of the professional process design, realized the full uniform cooling, high efficiency.

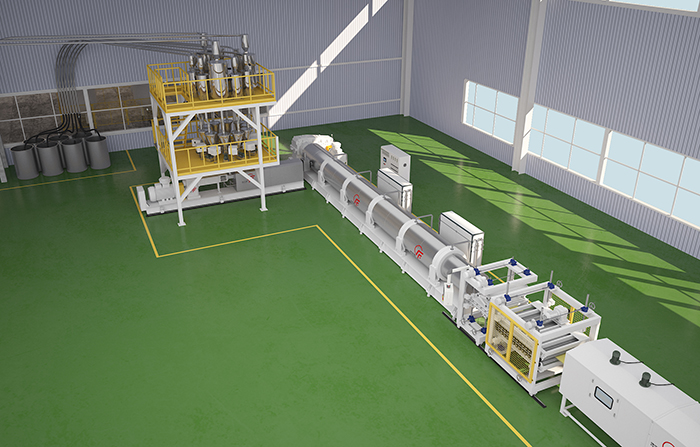

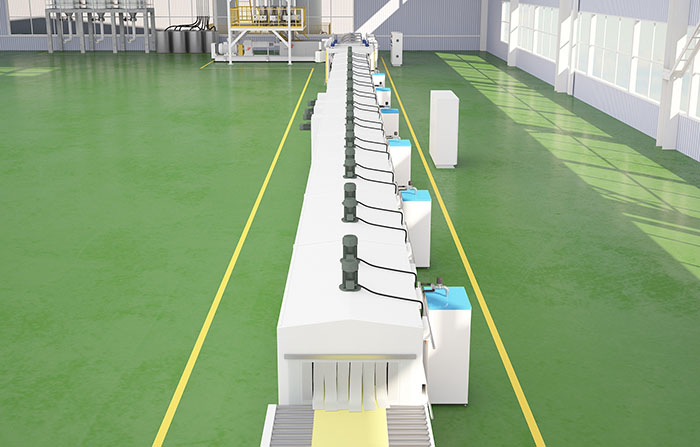

The XPS foam board production line is mainly used for the production of the xps foam insulation board. XPS material has the advantages of good elasticity, good cushioning, softness, non-toxicity, compression resistance, heat insulation, sound insulation, and moisture resistance.

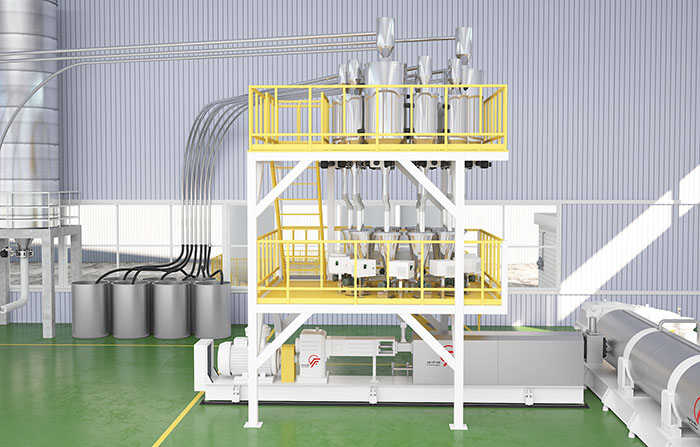

XPS foam board extrusion line is made of polystyrene, and the foaming agent is injected into the XPS machine. The finished xps foam insulation board is made through processes. The xps insulation board has a closed-cell structure, with the characteristics of lightweight, good strength, good airtightness, and anti-aging characteristics.

Weight(Tons)60

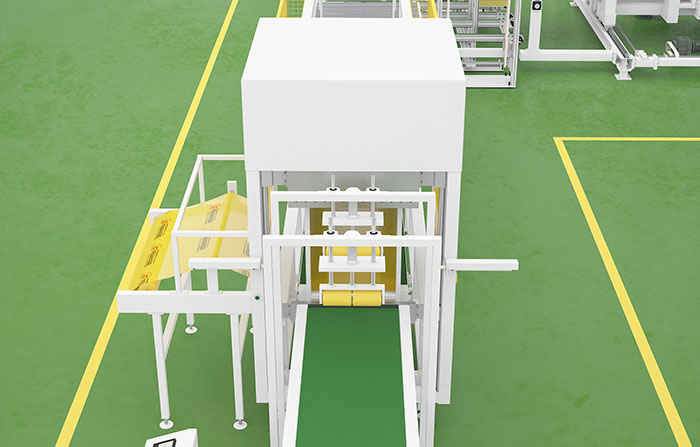

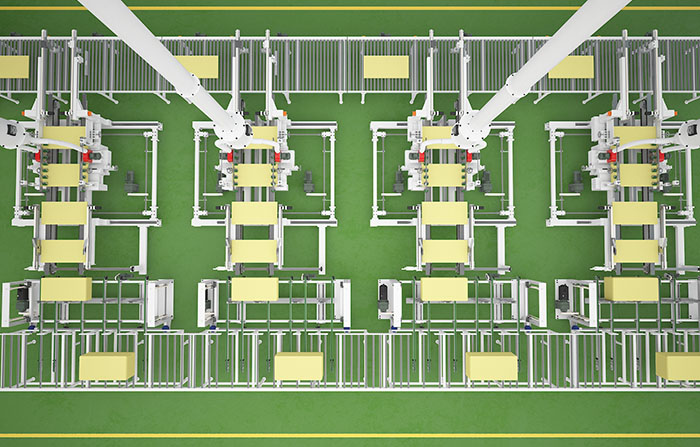

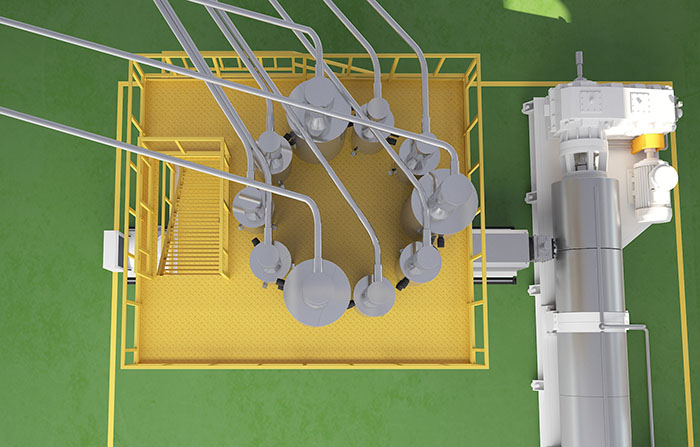

Continuous and even feeding is the first step to produce excellent products. All recipe changes can be done through a digital setting. Incorporated with DCS intelligent control system, it can manage production and contain cost more effectively.

Continuous and even feeding is the first step to produce excellent products. All recipe changes can be done through a digital setting. Incorporated with DCS intelligent control system, it can manage production and contain cost more effectively.

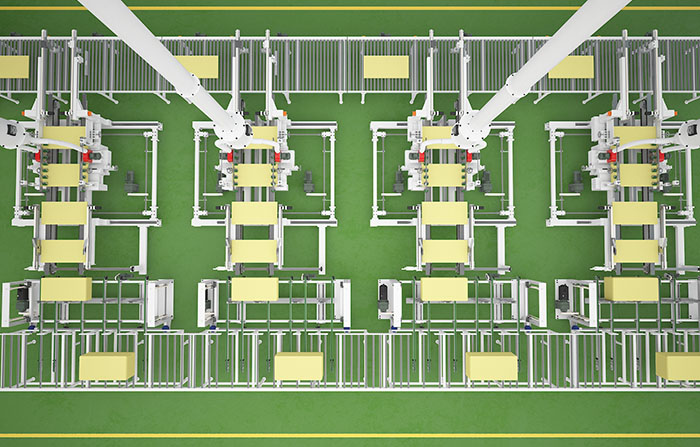

At China Feininger, we take pride in leading the industry with our XPS Foam Board Production Line, which incorporates the most advanced CO2 foaming technology available today. Our state-of-the-art production line is designed to meet the highest standards of efficiency and environmental sustainability. Utilizing carbon dioxide as a blowing agent, this technology enables the production of XPS foam boards that are not only eco-friendlier but also feature enhanced thermal insulation properties and superior mechanical strength.

The CO2 foaming process at China Feininger is meticulously controlled to optimize the cell structure of the foam, ensuring consistent quality and performance across all products. This method significantly reduces the emission of harmful substances and aligns with global environmental protection standards, reflecting our commitment to innovation and sustainability. As the first professional manufacturer in China specializing in both XPS foam production and the development of corresponding equipment, China Feininger continues to set industry benchmarks. Our advanced CO2 foaming technology represents a leap forward in making building materials safer, more effective, and more environmentally responsible.

Recommended Products

Inquiry

For the purchase, use, repair and maintenance of the product, you can contact us here

Solve parts, after-sales and service related problemsgo and have a look~

Send email to Feininger customer service centermarket@feininger.cn

08:30-17:00 from Monday to Saturday