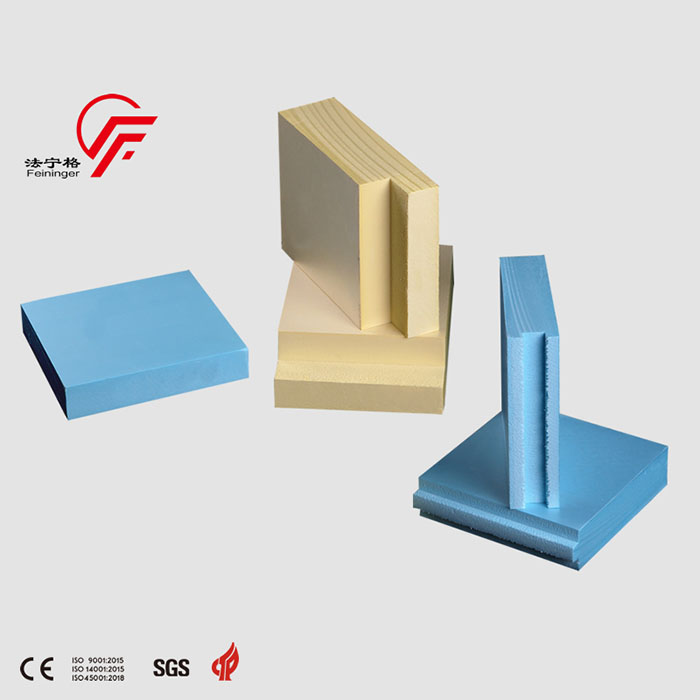

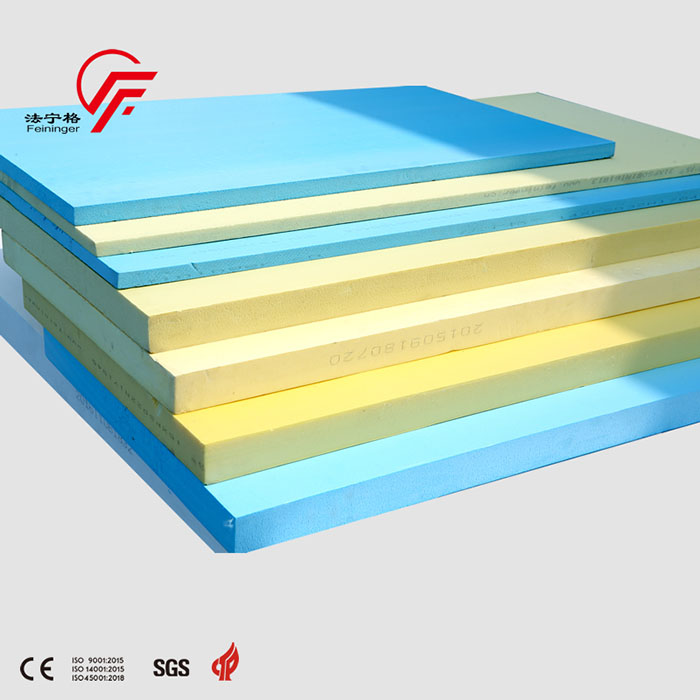

- Extruded Polystyrene Foam starts as solid pellets of polystyrene resin.

- We first feed the plastic pellets into an extruder where they are melted and mixed with critical additives to form a viscous liquid.

- Then we inject a blowing agent to expand the plastic product.

- Under well-controlled heat and pressure, the plastic mixture is forced through a mould to form the desired shape.

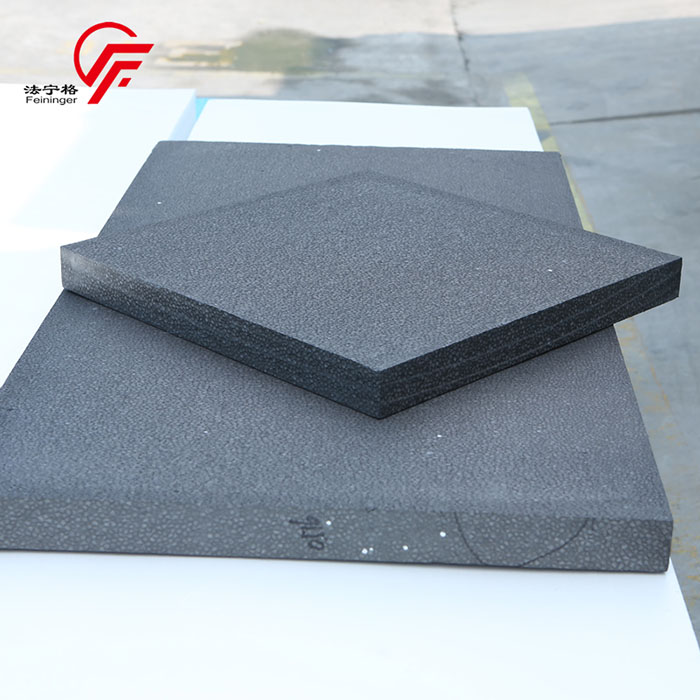

- Finally, the rigid foam is trimmed to a custom size and this is the final XPS foam board.

Extruded Polystyrene Foam starts as solid pellets of polystyrene resin. We first feed the plastic pellets into an extruder where they are melted and mixed with critical additives to form a viscous liquid. Then we inject a blowing agent to expand the plastic product. Under well-controlled heat and pressure, the plastic mixture is forced through a mould to form the desired shape. Finally, the rigid foam is trimmed to a custom size and this is the final XPS foam board.

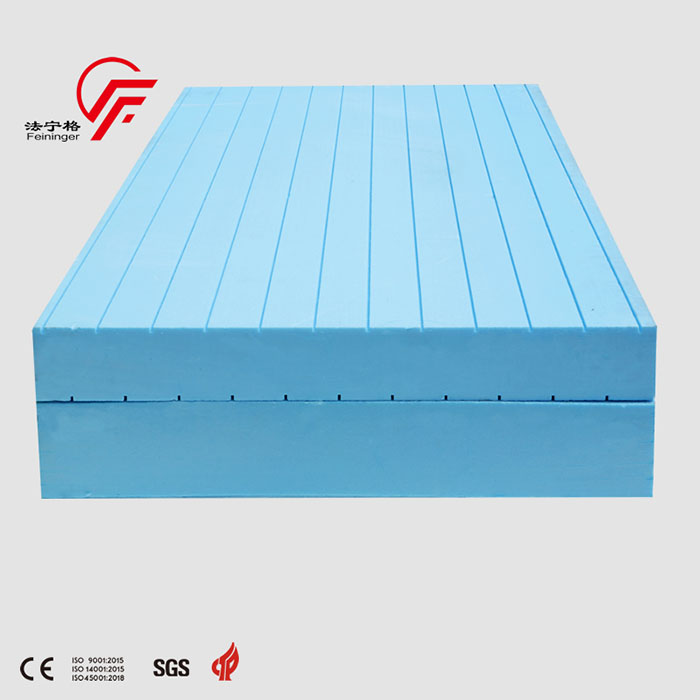

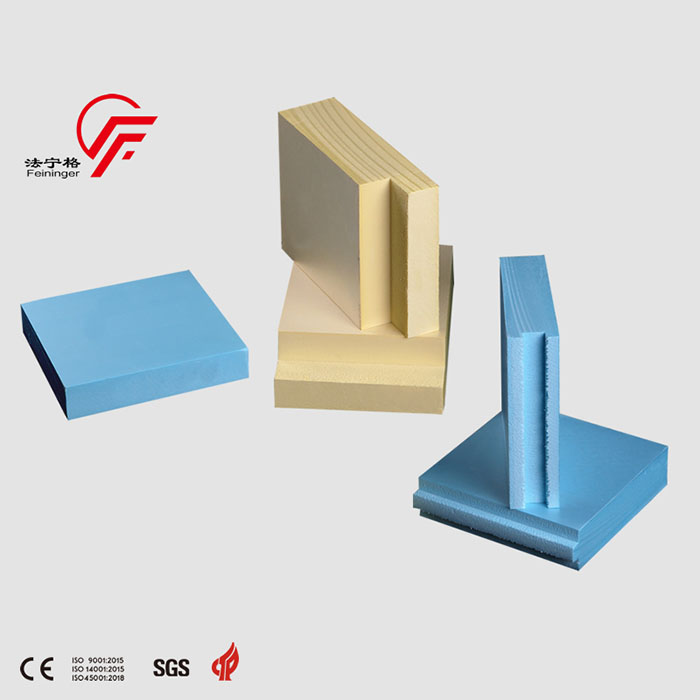

(1) Superior thermal Insulation

XPS insulation board has dense surface layer and closed-cell structure inner layer. Its thermal conductivity is much lower than EPS, so it has better thermal insulation performance than EPS. For the same exterior walls, its thickness can be less than other types of insulation materials.

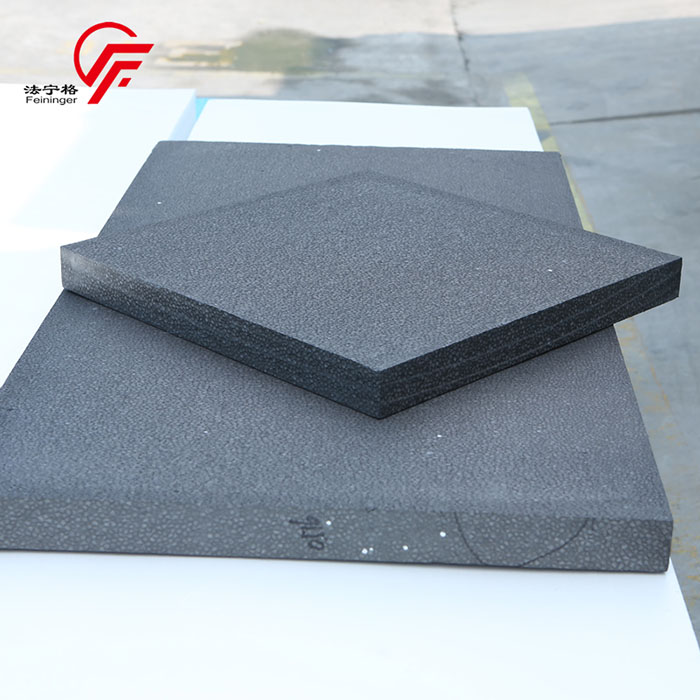

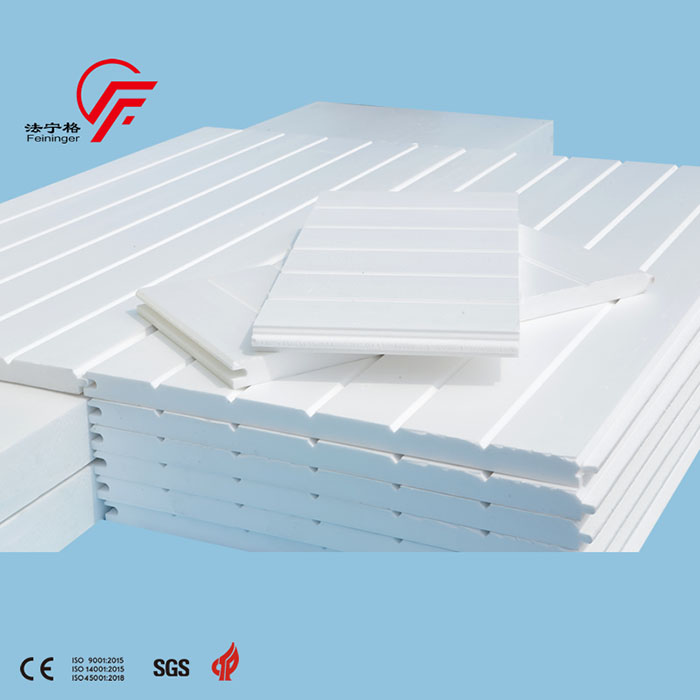

(1) Green and Eco-friendly

Feininger XPS foam board adopts the most advanced CO2 foaming technology, 100% Freon (CFC and HCFC) free production process, which will not destroy the ozone layer.

Therefore, our XPS foam board has higher density and is more eco-friendly. Also, there are no radioactive or volatile substances, free of formaldehyde, safe and environmentally friendly for indoor use.

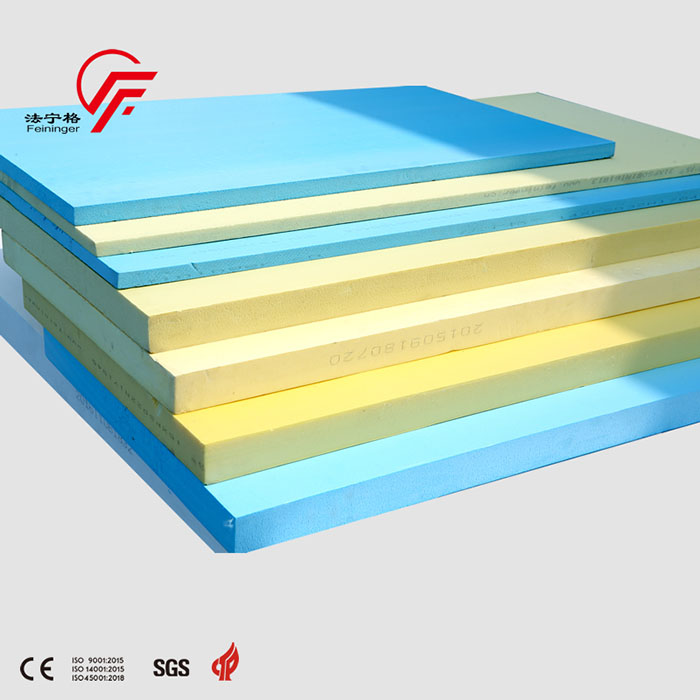

(2) Multiple capacity options

Feininger offers customized service. We can produce different specifications of XPS insulation board to meet the market and customer needs.

(3) Excellent after-sales team

We have domestic and foreign XPS extruded board experts who are providing 24-hour online service.

(4) Own many international certifications and technology patents, such as ISO9001:2008, ISO14001:2004 and CE

(5) Demonstration unit of world environmental protection organization and president unit of China Polystyrene Association.

(6) Developed and manufactured the first extruded polystyrene foam production line in China.

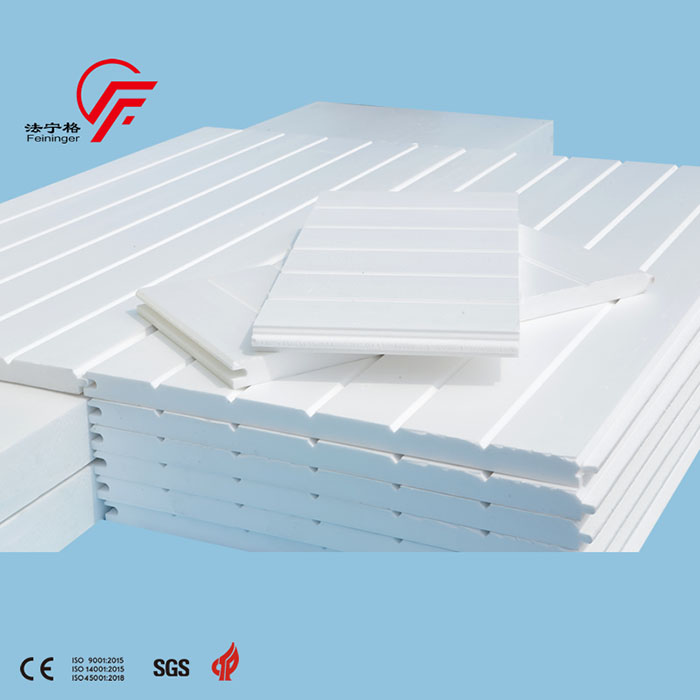

XPS extruded insulation board has superior insulation performance, excellent vapor barrier property, and extremely low water absorption under high humidity environments

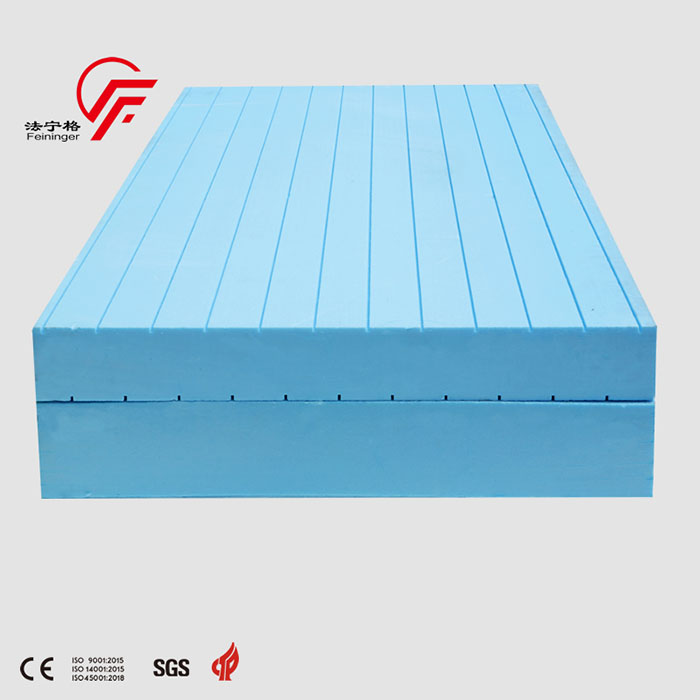

(1) Civil Engineering

XPS extruded foam board can settle the problem of water channels frost cracking in canal engineering in cold regions. In the South to North Water Diversion Project XPS boards were used as the anti-frost material of the channel. The bonding strength is high between Feininger XPS foam boards and concrete layers. The engineering practise applications show that the XPS board can meet the requirements of mechanized concrete construction.

(2) Cold Storage Purification Engineering

XPS foam boards can prevent moisture condensation effectively. Therefore, this material is widely used in cold storage rooms with superior resistance to water vapor penetration and high compression performance.

(3) Building Insulation and Decoration Field

Usually, about 15%-20% of the heat loss is through the floor/roof in buildings, so it's very important to offer dwellers a comfortable environment by effective insulation treatment to avoid condensation on the floor/roof. XPS foam board as building insulation has incomparable advantages. It can be used in the following fields.

* Roof insulation system

* Wall insulation system

* Floor insulation system

* Basement insulation system

* All kinds of composite sandwich panels

* Decorative molding

* Decorate condole top

Recommended Products

Inquiry

For the purchase, use, repair and maintenance of the product, you can contact us here

Solve parts, after-sales and service related problemsgo and have a look~

Send email to Feininger customer service centermarket@feininger.cn

08:30-17:00 from Monday to Saturday