Technology

05

Jan . 2024Welcome to our blog post on the benefits of using EPP Beads Foam in your production line! If you're looking for a cost-effective and durable solution for your business, then you've come to the right place. In this article, we will explore how EPP Beads Foam can revolutionize your manufacturing process and help you achieve greater efficiency and sustainability. So, let's dive in and discover why businesses around the world are turning to EPP Beads Foam as their go-to material for production.

EPP (Expanded Polypropylene) beads foam is gaining popularity in various industries due to its numerous advantages. In the production line, using EPP beads foam offers several benefits that can enhance efficiency and productivity.

One of the major advantages of EPP beads foam is its lightweight nature. This makes it easy to handle and transport within the production line, reducing labor costs and minimizing the risk of injuries for workers. Additionally, being lightweight also means that less energy is required during transportation, making it an environmentally friendly option.

Another advantage is the exceptional shock-absorption properties of EPP beads foam. It provides excellent cushioning and impact resistance, protecting delicate or fragile products during handling or transportation. This reduces product damage and ultimately saves businesses money by eliminating costly repairs or replacements.

Furthermore, EPP beads foam has excellent thermal insulation capabilities. It helps maintain a stable temperature inside packaging materials or containers during storage or transit. This feature is particularly beneficial for industries dealing with temperature-sensitive goods such as pharmaceuticals or food items.

Moreover, EPP beads foam is highly durable and long-lasting compared to other packaging materials like traditional foams or cardboard boxes. Its ability to withstand repeated use ensures cost savings over time since businesses won't need to frequently replace damaged packaging materials.

EPP beads foam can be easily customized according to specific requirements. It can be molded into different shapes and sizes to fit various products perfectly while providing optimum protection.

Incorporating EPP beads foam into your production line offers multiple advantages including lightweight design for easy handling, exceptional shock absorption properties for product protection, thermal insulation capabilities for temperature-sensitive goods' preservation, durability leading to cost savings over time,and customization options based on specific needs

One of the key advantages of using EPP Beads Foam in your production line is that it provides a cost-effective solution for businesses. With rising costs and increasing competition, finding ways to reduce expenses without compromising on quality has become crucial for companies across various industries.

EPP Beads Foam offers significant cost savings compared to other materials commonly used in manufacturing processes. Its lightweight nature means reduced transportation costs as less fuel is required to move the products from one place to another. Additionally, EPP Beads Foam is highly durable and long-lasting, minimizing maintenance and replacement costs over time.

Another cost-saving aspect of EPP Beads Foam is its ability to be molded into intricate shapes with minimal material wastage. This ensures that businesses can optimize their production efficiency while reducing raw material consumption and waste disposal expenses.

Furthermore, EPP Beads Foam's excellent insulating properties help businesses save on energy costs by maintaining stable temperatures during storage or transportation. It also acts as a shock absorber, protecting goods from damage and reducing the risk of costly product returns or replacements.

By incorporating EPP Beads Foam into their production line, businesses can effectively cut down on overall operational expenses while still delivering high-quality products to their customers. This makes it an attractive choice for manufacturers looking for a cost-effective solution that does not compromise on performance or sustainability.

Durability and sustainability are two key factors to consider when choosing materials for your production line. With EPP Beads Foam, you can rest assured knowing that you have a solution that excels in both areas.

Let's talk about durability. EPP Beads Foam is known for its exceptional strength and resilience. It has the ability to withstand repeated impacts without losing its shape or structural integrity. This makes it an ideal choice for packaging materials, automotive components, and even furniture.

Moreover, EPP Beads Foam is highly resistant to chemicals, UV radiation, and extreme temperatures. This means that it won't degrade or deteriorate over time like other materials might. Its long lifespan ensures that you get the most out of your investment.

When it comes to sustainability, EPP Beads Foam truly shines. It is 100% recyclable and can be reused numerous times without any loss in quality or performance. Additionally, the manufacturing process of EPP Beads Foam requires less energy compared to other foam materials.

By incorporating EPP Beads Foam into your production line, you are not only choosing a durable material but also making a positive impact on the environment by reducing waste and energy consumption.

In conclusion, opting for EPP Beads Foam in your production line offers undeniable benefits in terms of durability and sustainability[X]. Its robust nature ensures longevity while its eco-friendly characteristics contribute towards a greener future. Consider integrating this versatile material into your manufacturing processes today!

EPP beads foam, often referred to as Expanded Polypropylene, is a versatile and highly durable material that has found its place in numerous industries. Let's explore some of the key applications where EPP beads foam shines.

In automotive manufacturing, EPP beads foam is widely used for impact absorption and energy management. It can be found in car bumpers, headrests, door panels, and even undercarriage components. Its lightweight nature combined with excellent shock resistance makes it an ideal choice for enhancing vehicle safety.

The electronics industry also benefits from the unique properties of EPP beads foam. It provides cushioning and protection during transportation of delicate electronic devices such as smartphones, tablets, and laptops. Additionally, it is used for insulation purposes due to its low thermal conductivity.

Another industry where EPP beads foam plays a vital role is logistics and packaging. Its ability to absorb impacts helps protect fragile goods like glassware or ceramics during transit. Moreover, its lightweight nature reduces shipping costs while ensuring product integrity.

In the sports equipment sector, EPP beads foam finds application in helmets for various activities including cycling and skiing. The material offers exceptional shock absorption capabilities while maintaining a comfortable fit for users.

Furthermore, the construction industry utilizes EPP beads foam primarily as insulation material due to its high thermal efficiency and moisture resistance properties. It helps improve energy efficiency by reducing heat transfer through walls or roofs.

These are just a few examples highlighting how diverse industries benefit from incorporating EPP beads foam into their production processes. With its cost-effectiveness, durability,and superior performance characteristics,EPP beads foam has become a key component in many manufacturing lines.

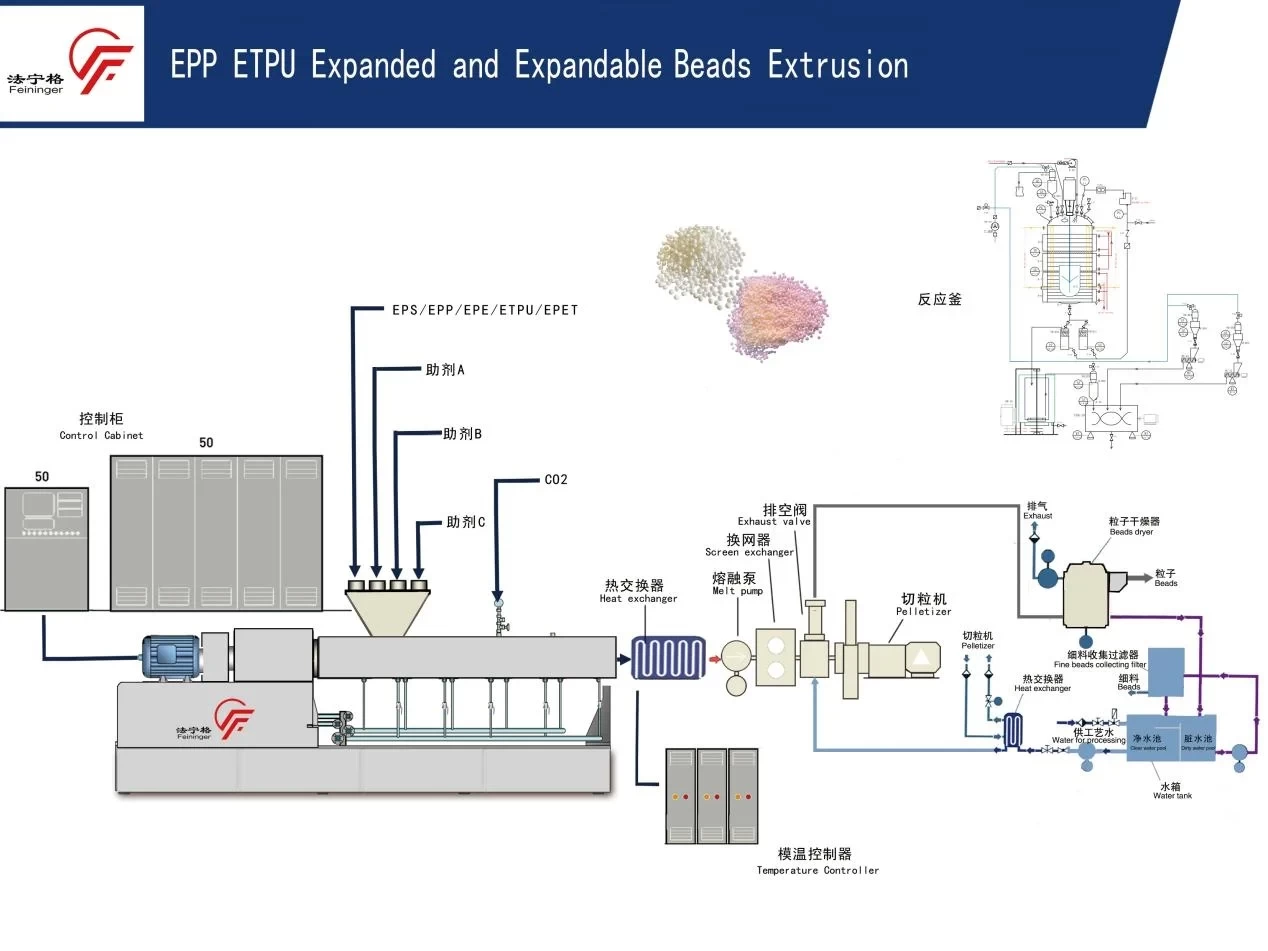

With ever-evolving applications and technologies such as China Feininger's advanced production line,it is innowonderthat the popularity of Epp beads foam continues to grow steadily across multiple industries.

In today's competitive business environment, it is crucial for companies to choose the right materials and technologies that can help streamline their production processes while reducing costs. EPP Beads Foam offers a cost-effective solution for businesses in various industries, delivering numerous advantages that set it apart from other foam materials.

By incorporating EPP Beads Foam into your production line, you can enjoy benefits such as its lightweight nature, high impact resistance, excellent thermal insulation properties, and recyclability. These features make it an ideal choice for applications in automotive manufacturing, packaging industry, sports equipment production, furniture manufacturing, and many more.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

07 Jun 2024

07 Jun 2024 Selecting the Right EPP Particle Machine: Key Features to Consider

When it comes to manufacturing with Expanded Polypropylene (EPP), the quality and efficiency of your production process heavily depend on the EPP particle machine you choose.

18 Sep 2023

18 Sep 2023 The difference between single screw and twin screw extruder

At present, domestic extruders can be roughly divided into two categories, one is a single screw extruder, one is a twin screw extruder.

05 Sep 2024

05 Sep 2024 Streamlining Operations with the Latest XPS Cornice Production Line Innovations

In today's competitive manufacturing landscape, businesses are always seeking ways to streamline operations, reduce costs, and enhance productivity.