Technology

05

Sep . 2024In today's competitive manufacturing landscape, businesses are always seeking ways to streamline operations, reduce costs, and enhance productivity. One of the key innovations in the industry is the use of XPS (Extruded Polystyrene) cornice production lines, which offer a highly efficient and sustainable solution for producing durable and aesthetically pleasing cornices.

At China Feininger, we are proud to lead the industry with our advanced XPS cornice production lines, specifically designed to improve operational efficiency while maintaining high product quality. Our production line innovations, including low-density extrusion molding and energy-saving technology, are helping manufacturers around the globe achieve better results.

One of the standout features of Feininger's XPS cornice production line is its low-density extrusion molding technology. This allows for the production of cornices that are both lightweight and durable, making them easier to transport, handle, and install. The high compressive strength of the XPS cornices ensures they maintain their structural integrity, even in demanding environments.

With Feininger’s extrusion molding process, manufacturers can produce large quantities of high-quality cornices without sacrificing durability or aesthetic appeal. This process helps streamline the production cycle, reducing downtime and improving overall operational efficiency.

Energy efficiency is a major concern in any manufacturing process, and Feininger has addressed this with the innovative gearbox and motor design in our XPS cornice production line. Our scientifically designed low-power motor minimizes energy consumption, allowing manufacturers to lower operational costs while maintaining high output.

This energy-efficient design does not compromise the quality of the product, ensuring that the cornices produced are of the highest standard. By reducing energy consumption, Feininger enables companies to achieve their production goals while contributing to a more sustainable and eco-friendly operation.

At Feininger, we understand that investing in new production line technologies can come with challenges, which is why we provide comprehensive training and technical guidance to all our clients. With our extensive experience in extruded profile production, we help our clients avoid costly detours and streamline their operations.

Our dedicated team works closely with manufacturers to ensure smooth integration of our XPS cornice production line into their existing operations. Whether it’s technical support, process optimization, or on-site training, Feininger ensures that our clients are fully equipped to maximize their production efficiency.

The versatility of Feininger's XPS cornice production line is another reason why it stands out in the industry. XPS cornices produced using our technology are suitable for a wide range of applications, from woodworking nailing and spray painting to home decoration and other pneumatic operations. This flexibility allows manufacturers to cater to various markets, from residential to commercial construction projects.

With the ability to produce high-quality cornices suitable for different applications, Feininger enables manufacturers to expand their product offerings and tap into new revenue streams.

When it comes to streamlining operations and enhancing productivity, China Feininger's XPS cornice production line is a game-changer. By leveraging the latest innovations in extrusion molding, energy efficiency, and comprehensive client support, we provide manufacturers with a competitive edge in the market.

Here's why Feininger's XPS cornice production line is the ideal choice for manufacturers looking to boost efficiency:

As the manufacturing industry continues to evolve, the need for efficient, sustainable, and cost-effective solutions has never been greater. China Feininger’s XPS cornice production line is designed to meet these demands, offering a range of innovative features that help manufacturers streamline their operations and improve productivity.

With Feininger's commitment to providing comprehensive support and cutting-edge technology, manufacturers can enjoy the benefits of reduced operational costs, increased efficiency, and a higher-quality product. Whether you're looking to produce cornices for home decoration or industrial purposes, Feininger’s XPS cornice production line is the ultimate solution for your business.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

24 Nov 2023

24 Nov 2023 Supercritical CO2 Foaming Technology

Supercritical CO2 foaming technology is an environmentally friendly method that can reduce waste and harm to the environment to a great extent.

08 Sep 2023

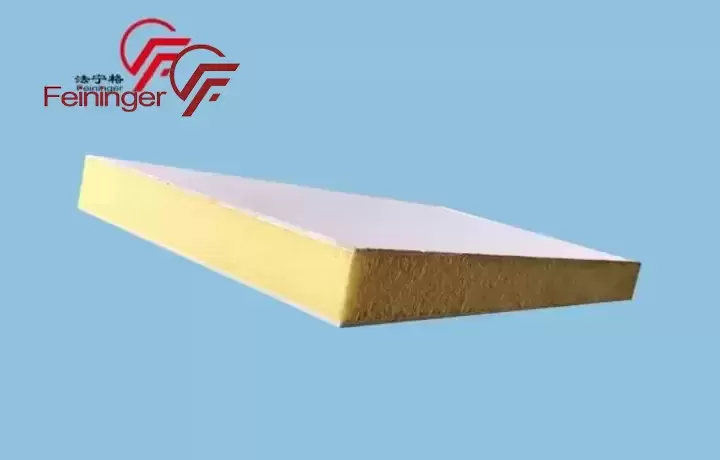

08 Sep 2023 Unveiling the Advantages of XPS with PVC Sandwich Panels in Construction

Are you looking for a game-changing solution to revolutionize your construction projects? Look no further than XPS with PVC sandwich panels.

13 Mar 2024

13 Mar 2024 The Advantages of Advanced EPP Beads Machines

In the world of protective packaging and lightweight construction materials, Expanded Polypropylene (EPP) beads stand out for their exceptional properties.