Technology

29

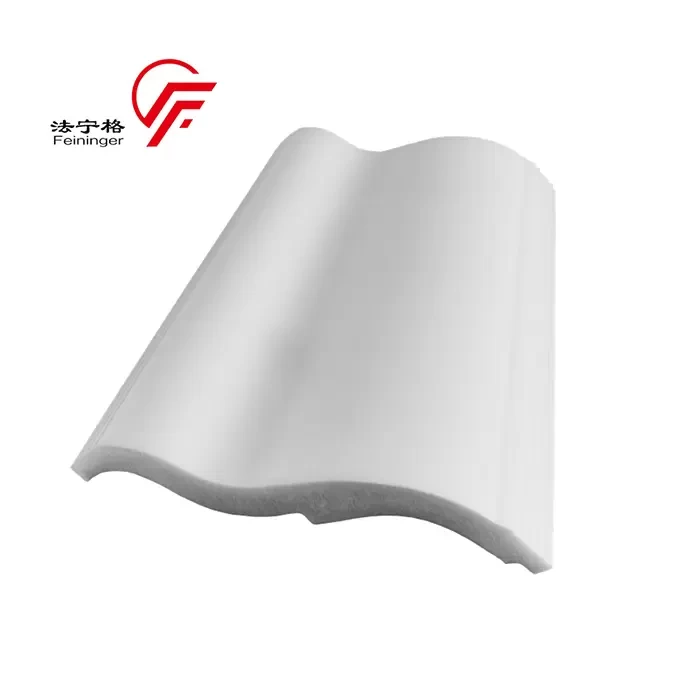

Aug . 2024When it comes to producing high-quality cornices for interior design, choosing the right material is crucial for both durability and flexibility in design. Extruded Polystyrene (XPS) has become a top choice for manufacturers looking to deliver both superior strength and versatility. XPS cornices offer an ideal combination of lightness, insulation, and compressive strength, making them perfect for a variety of architectural applications.

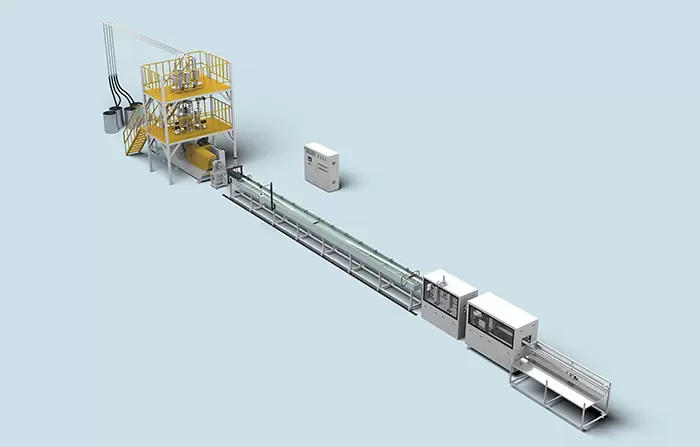

At China Feininger, we specialize in providing cutting-edge XPS cornice production lines that deliver high-performance results. Our production lines utilize 100% CO2 foaming technology, ensuring eco-friendly and efficient manufacturing processes.

One of the most significant benefits of using XPS for cornice production is its outstanding durability. XPS material is known for its high compressive strength, making it resilient enough to withstand impact and wear over time. This durability ensures that cornices made from XPS maintain their shape and quality, even in high-traffic areas or harsh environmental conditions.

China Feininger's XPS cornice production line is designed with durability in mind. The extrusion molding process we use provides XPS cornices with reliable structural integrity. Our systems are equipped with scientifically configured feed systems and temperature-controlled foaming agent injection systems, allowing for optimal heat exchange and high-quality production results.

Another major advantage of XPS is its flexibility in design. XPS cornices can be easily molded into various shapes and sizes, making it an ideal material for creating intricate architectural details. Whether you're producing classic or modern cornices, XPS can be tailored to meet a wide range of aesthetic preferences.

At Feininger, our XPS cornice production lines are designed to maximize flexibility. We offer free training and technical guidance to our clients, ensuring that you can efficiently produce custom profiles without any production setbacks. The extrusion process allows for smooth, consistent shaping, enabling manufacturers to achieve the highest level of precision in every cornice produced.

In today's environmentally conscious world, sustainable manufacturing practices are more important than ever. XPS production is known for its lower environmental impact compared to other materials, especially when using advanced technologies.

Feininger's XPS cornice production line utilizes 100% CO2 foaming technology, which is not only eco-friendly but also ensures the quality of the foamed product. Our system includes a heat exchanger for efficient temperature control, reducing the overall energy consumption of the production process. The result is a durable, high-quality cornice produced in an environmentally responsible way.

At Feininger, we understand the importance of balancing quality with efficiency. That’s why our XPS cornice production lines are equipped with a scientifically designed gearbox and low-power motor. This system reduces energy consumption while maintaining high output levels, making our production line both cost-effective and eco-friendly.

Our experience in extruded profile production allows us to offer clients free training and technical guidance to optimize their production processes, ensuring you avoid unnecessary detours and inefficiencies.

Choosing XPS for cornice production offers unparalleled benefits in terms of durability and design flexibility. XPS cornices are lightweight yet strong, with a production process that allows for precise, intricate designs. By utilizing Feininger’s XPS cornice production line, manufacturers gain access to an eco-friendly, energy-efficient, and cost-effective production solution.

At China Feininger, we pride ourselves on providing the best technology and support to help our clients succeed. Whether you're producing cornices for residential or commercial projects, our XPS cornice production line offers the durability, flexibility, and efficiency you need to stay competitive in the market.

Let Feininger help you take your cornice production to the next level.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

16 Aug 2023

16 Aug 2023 Difference Between Physical Foaming and Chemical Foaming

Foam, with its unique structure and versatile properties, can be crafted using various methodologies, primarily bifurcated into two dominant techniques: physical and chemical foaming. Though both aim to introduce air bubbles or pockets into materials, the mechanisms and intricacies behind each process are markedly different.

07 Mar 2024

07 Mar 2024 XPS Decorative Moulding: Enhance Interiors with Style

Are you seeking to elevate your space with a touch of elegance and sophistication? Look no further than XPS decorative moulding. Transforming ordinary rooms into extraordinary spaces, XPS decorative moulding offers a seamless way to add charm and character to your home or office.

26 Feb 2024

26 Feb 2024 Feininger to Showcase Cutting-Edge XPS Technology at UzBuild - Uzbekistan International Exhibition 2024

Feininger, the pioneering manufacturer of XPS Extrusion Line and XPS Foam Board based in China, is poised to make a significant impact at the highly anticipated UzBuild - Uzbekistan International Exhibition 2024.