Technology

22

Aug . 2024In today's fast-paced world of material science and product innovation, foam sheet laboratory machines are integral tools that enable researchers, engineers, and product developers to explore new materials and optimize production processes. These versatile machines play a critical role in testing, prototyping, and the development of advanced foam materials for a wide range of applications. In this blog, we’ll dive into some of the top applications of foam sheet laboratory machines in material testing and development, while highlighting the high-performance solutions offered by Feininger.

One of the primary applications of foam sheet laboratory machines is in material research and prototyping. These machines allow researchers to test various thermoplastic materials such as PBAT, PA, and PET in small batches. The ability to precisely control processing parameters like temperature, pressure, and material composition enables researchers to experiment with different formulations and rapidly develop prototypes. Feininger’s foam sheet laboratory machines, with a feeding capacity of 20-30 kg/h, are perfect for such research applications, providing the flexibility needed to fine-tune formulations and achieve optimal results.

The packaging industry is a major consumer of foam materials, with applications ranging from protective packaging to thermal insulation. Foam sheet laboratory machines are crucial in developing lightweight, durable, and customizable foam sheets that meet the specific requirements of packaging applications. Feininger’s equipment, featuring a complete system that includes a loss-in-weight feeding system, foam agent injection system, and cutting system, is designed to produce high-quality foam sheets with consistent properties. This ensures that the final products are fit for use in demanding packaging environments.

In industries like automotive and aerospace, foam materials are used for insulation, cushioning, and lightweight structural components. Testing foam sheets for these applications requires precision and control, as even minor variations in material properties can have significant effects on performance and safety. Feininger’s laboratory machines provide the capability to produce custom foam sheets for testing and validation in these high-stakes industries. The inclusion of advanced systems like a melt pump, static mixer, and slot die ensures uniform material distribution and quality, which is essential for producing reliable test samples.

Foam sheets are commonly used in construction for applications such as insulation, soundproofing, and impact absorption. The ability to customize the properties of foam sheets—such as density, thermal resistance, and moisture resistance—is crucial for meeting the diverse needs of the building and construction industry. Feininger’s foam sheet laboratory machines are equipped with a screw extruder (available in single extruder and 2-stages extruder options) that allows developers to tailor material characteristics for specific construction applications. This capability accelerates the development of new, more efficient building materials.

The consumer electronics and appliance industries rely heavily on foam materials for insulation and shock absorption. Foam sheet laboratory machines enable manufacturers to develop materials that provide the right balance between protection, insulation, and weight. Feininger’s machines are designed to deliver high-quality, consistent foam sheets suitable for testing in electronic housings, refrigerators, and other appliances. By controlling the material formulation and processing conditions, developers can optimize the performance of insulation materials for specific product requirements.

With growing demand for eco-friendly and sustainable products, foam sheet laboratory machines play a key role in developing biodegradable and recyclable foam materials. Whether it's creating foam sheets from bio-based materials like PBAT or optimizing the recycling process for thermoplastics, these machines provide the tools needed for innovative environmental solutions. Feininger’s systems are adaptable to a wide range of materials, making it easier for researchers to explore sustainable alternatives and bring them to market.

Foam sheet laboratory machines are invaluable in academic settings, where they support a wide range of research projects. Universities and research institutions use these machines to conduct experiments on new materials, study foam properties, and develop advanced manufacturing techniques. Feininger’s equipment, known for its reliability and customization options, is particularly suited for these environments, providing students and researchers with the ability to conduct high-quality experiments and gather valuable data.

Feininger offers advanced foam sheet laboratory machines designed for versatility, precision, and scalability. Each system is carefully engineered to meet the diverse needs of both research institutions and commercial enterprises.

Feeding Capacity: The test equipment has a feeding capacity of 20-30 kg/h (customizable based on material characteristics).

Complete Equipment Composition: The system includes a loss-in-weight feeding system, foam agent injection system, screw extruder (single or 2-stages), melt pump, static mixer, slot die, and cutting system.

Customization and Flexibility: Feininger’s equipment can be tailored to produce foam sheets with specific properties, supporting a wide range of applications from packaging to high-tech components.

Precision and Consistency: With advanced control systems and high-quality components, Feininger’s machines ensure consistent output, which is critical for reliable testing and development.

Foam sheet laboratory machines are essential tools for material testing, product development, and innovation across a broad spectrum of industries. Whether you’re developing packaging solutions, testing automotive components, or exploring sustainable materials, having the right equipment is crucial. Feininger’s comprehensive solutions provide the flexibility, precision, and reliability needed to achieve exceptional results in your research and development efforts.

For more information about Feininger’s foam sheet laboratory machines and how they can support your material testing and development projects, visit our website or contact our team of experts.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

19 Jun 2024

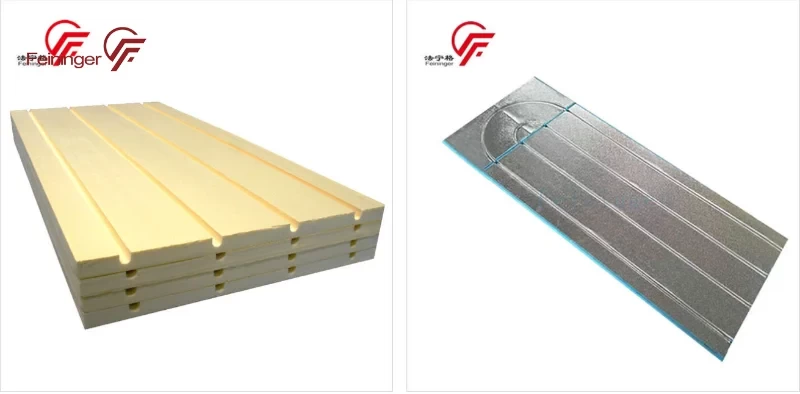

19 Jun 2024 Comparing Insulation Materials: Where Does XPS Foam Board with Aluminum Foil Stand?

In the world of insulation materials, the choices can seem endless. Among these, XPS (Extruded Polystyrene) foam board with aluminum foil has become a significant player, particularly in scenarios requiring robust thermal resistance and moisture protection.

10 Oct 2023

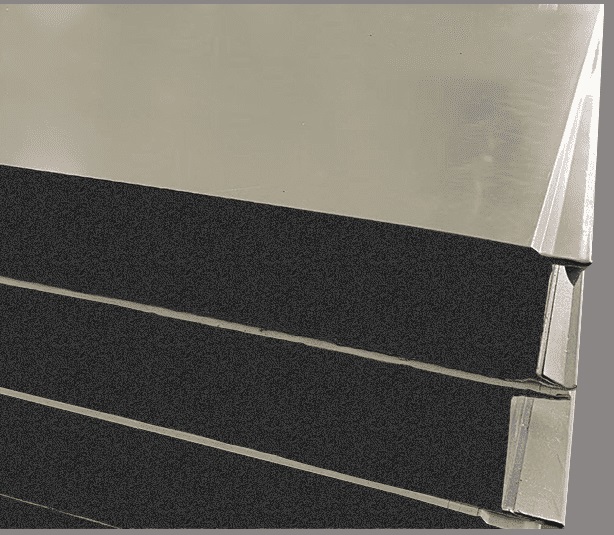

10 Oct 2023 Graphene polystyrene insulation sandwich panel (GPI)

Graphene polystyrene insulation sandwich panel (GPI) refers to a rigid foam with closed-cell structure formed by extrusion and foaming, with polystyrene resin or its copolymer as the main component, adding graphene and other additives.

01 Dec 2023

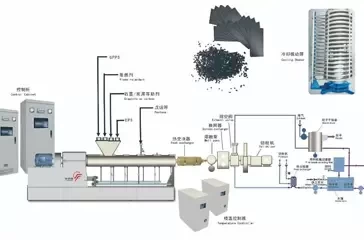

01 Dec 2023 Maximizing Efficiency: The Advantages of EPS Beads Foam Extrusion Line

Are you in the manufacturing industry and looking for ways to boost efficiency while saving on costs? Look no further than the revolutionary EPS Beads Foam Extrusion Line.