Technology

24

Nov . 2023With the gradual improvement of environmental awareness, more and more companies are beginning to pay attention to the issue of sustainable development and explore more environmentally friendly production methods. Supercritical CO2 foaming technology is an environmentally friendly method that can reduce waste and harm to the environment to a great extent.

Supercritical CO2 foaming is a technology that uses supercritical fluids to foam plastics. Supercritical fluid is a high-viscosity, high-density substance with strong permeability and lubricity. Put the plastic sample into supercritical CO2, and then quickly cool down and the pressure will drop suddenly, causing the CO2 to be quickly released from the plastic, and the plastic sample will form small bubbles, thereby achieving the foaming effect. During this process, CO2 will evaporate quickly from the medium without causing any pollution to the environment in the process.

Supercritical CO2 foaming can be used not only to produce plastic products, but also to produce foam materials and various polymer materials. Supercritical CO2 foaming technology can reduce production waste and CO2 emissions, while also reducing production costs.

Traditional foaming technology usually uses Freon, a toxic substance. This substance will be released during the foaming process, which is very harmful to the environment and human health. Supercritical CO2 foaming technology is a new environmentally friendly technology that can reduce or even completely eliminate the use of toxic substances, thereby minimizing environmental pollution and the impact on people's health.

In the future, as people gain a deeper understanding of environmental protection issues, supercritical CO2 foaming technology will be more widely used. Through this technology, we can produce more environmentally friendly and sustainable products and reduce environmental harm during the production process, which is beneficial to human health and future sustainable development.

In short, supercritical CO2 foaming technology is an innovative environmentally friendly technology that makes our production more environmentally friendly and sustainable. Although there are still some problems that need to be solved, I believe that with the continuous development and improvement of technology, we will see more people begin to adopt this technology, so that environmental protection and industrial development are no longer two conflicting goals.

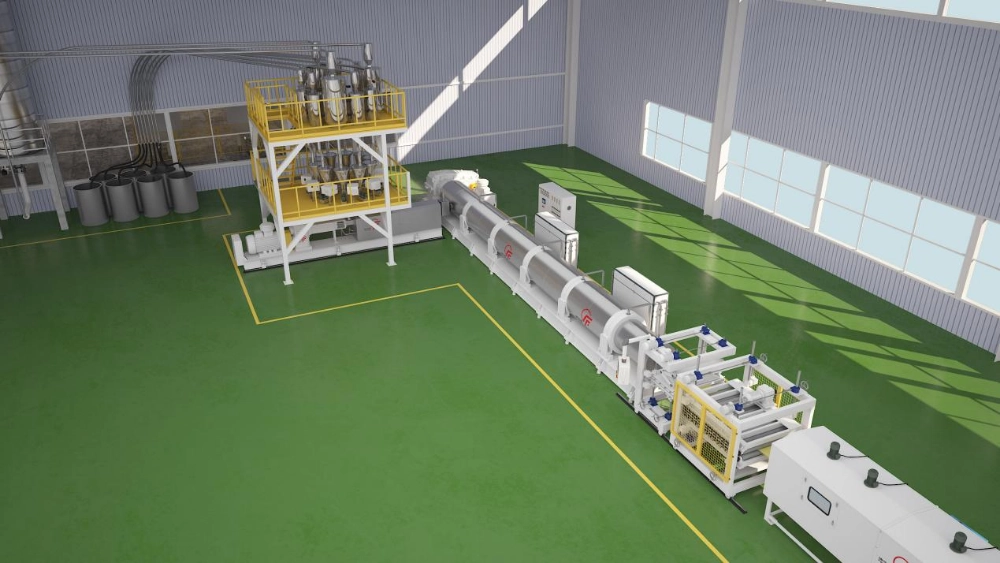

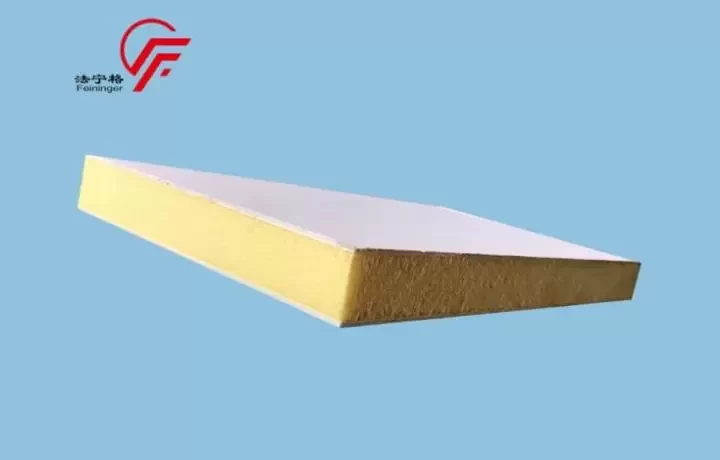

Feininger is the leading manufacturer in China specializing in the production of XPS extrusion lines and XPS foam boards. We proudly stand as the country's premier enterprise dedicated to the research, development, manufacturing, and sales of both XPS foam and XPS equipment. Leveraging cutting-edge technology, particularly the use of supercritical CO2 foaming, we employ a revolutionary technique that utilizes supercritical fluid to foam plastics. This advanced approach underscores our commitment to innovation and positions Feininger as the sole domestic entity engaged in the comprehensive production and advancement of XPS foam materials and equipment.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

05 Sep 2024

05 Sep 2024 Streamlining Operations with the Latest XPS Cornice Production Line Innovations

In today's competitive manufacturing landscape, businesses are always seeking ways to streamline operations, reduce costs, and enhance productivity.

18 Sep 2023

18 Sep 2023 The difference between single screw and twin screw extruder

At present, domestic extruders can be roughly divided into two categories, one is a single screw extruder, one is a twin screw extruder.

18 Feb 2025

18 Feb 2025 Step-by-Step Guide to Setting Up an XPS Foam Board Production Line

The demand for high-quality, energy-efficient insulation materials has grown significantly in recent years, and one of the most popular choices for insulation is XPS foam board.