Technology

18

Feb . 2025The demand for high-quality, energy-efficient insulation materials has grown significantly in recent years, and one of the most popular choices for insulation is XPS foam board. Known for its durability, excellent thermal insulation properties, and low moisture absorption, XPS foam is widely used in construction, packaging, and other industries. If you're considering setting up your own XPS foam board production line, this step-by-step guide will help you navigate the process and ensure you invest in the right equipment for your business needs.

XPS foam board production involves several key steps, including raw material preparation, extrusion, and cooling. The raw materials—typically polystyrene resin, foaming agents, and additives—are combined in an extruder to form a solid, dense foam material. The extruded foam then undergoes cooling to solidify and achieve the desired thickness and density.

Key Characteristics of an Efficient XPS Foam Board Production Line:

A reliable XPS Foam Board Production Line supplier, such as Feininger, will provide the latest technology to ensure your production process is both efficient and cost-effective.

When setting up an XPS foam board production line, selecting the right supplier is critical. Look for companies with advanced technology, solid experience, and an excellent track record. Feininger is a well-established XPS foam board production line supplier, known for their high-output, low-energy, and efficient production lines. Their equipment is designed with:

Feininger's XPS foam board production line offers cutting-edge technology that makes the entire process more efficient, helping you increase your output while lowering costs.

Before installing your production line, you need to plan the factory layout carefully. Consider the following factors:

Feininger’s XPS foam board production line is designed with a scientific layout that minimizes space usage while ensuring a smooth workflow.

Once your equipment is chosen, the next step is installation. Feininger offers free technical guidance to help you with the setup process. Their team will assist with everything from assembly to calibration, ensuring that the production line runs smoothly from day one.

Why Technical Guidance Matters:

After the installation is complete, it's time to train your team. Effective training is crucial for ensuring smooth operations and maximizing production efficiency. Feininger’s technical team will also offer on-site training to your staff, covering all aspects of the production process, including raw material handling, machine operation, and maintenance.

Following installation, it's also important to conduct operational testing to ensure everything runs according to specifications. This involves running sample batches and adjusting settings to optimize product quality.

Once the production line is running, you’ll need to monitor its performance regularly. Regular checks and maintenance are essential for keeping the system running smoothly and reducing downtime.

Feininger’s XPS foam board production line features low maintenance requirements, thanks to its high-quality materials and design. However, it’s still important to establish a routine for cleaning, checking for wear and tear, and ensuring that all parts are functioning as expected.

Key Maintenance Tips:

Setting up an XPS foam board production line is an investment that requires careful planning and the right equipment. By choosing a reliable supplier like Feininger, you gain access to high-quality, energy-efficient, and technologically advanced equipment that can help your business thrive in the competitive insulation materials market. From technical guidance to operational support, Feininger ensures that your production line will run smoothly and efficiently, helping you meet the growing demand for quality XPS foam board products.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

08 Dec 2023

08 Dec 2023 How to choose extruded board manufacturers?

There are a variety of thermal insulation products in the building thermal insulation material market, and extruded plastic boards are favored by consumers because of their health and environmental protection and excellent physical and chemical properties.

10 Sep 2024

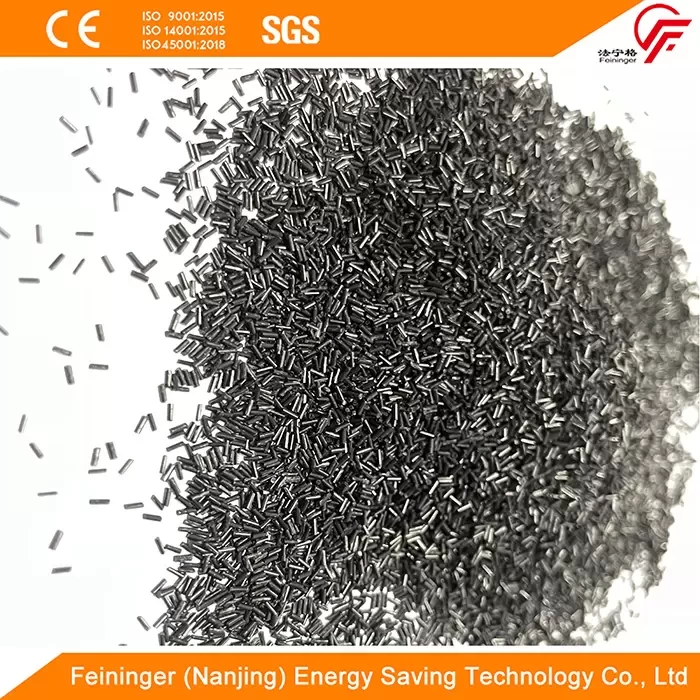

10 Sep 2024 Exploring the Benefits of EPS Graphite Particles for Enhanced Insulation

Expanded Polystyrene (EPS) has long been recognized as an effective insulation material. However, EPS Graphite Particles take the insulation game to the next level.

28 Mar 2024

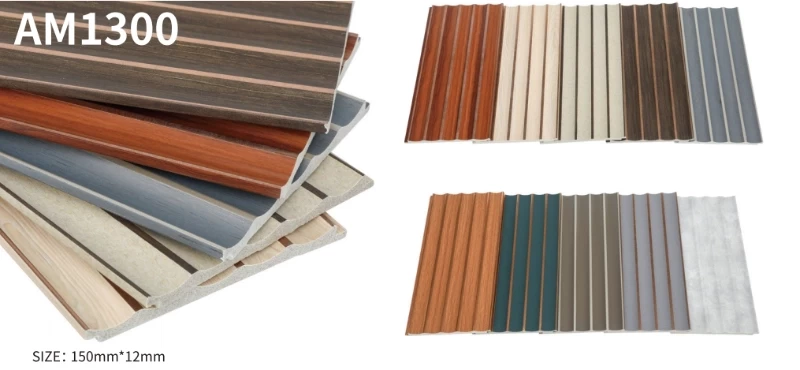

28 Mar 2024 Transforming Spaces: The Versatility of Partition Wall Panels

In the ever-evolving world of interior design and architecture, the need for flexible and innovative solutions to divide and optimize spaces has never been more paramount. Partition wall panels have emerged as a versatile and efficient tool to meet this demand.