Technology

28

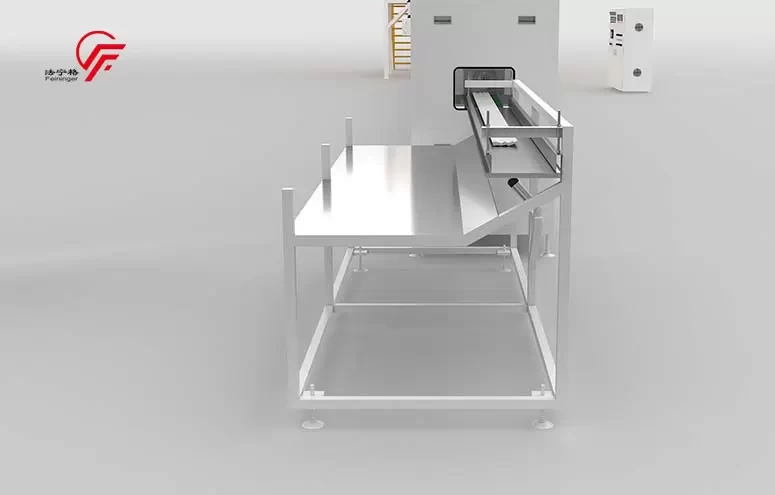

Feb . 2025In the ever-evolving world of construction and architectural design, XPS (extruded polystyrene) foam is rapidly gaining popularity as a versatile material for moldings and decorative elements. The XPS Cornice Production Line, such as the Feininger XPS Cornice Production Line, is a significant innovation that provides a high-quality solution for producing durable and lightweight cornices with outstanding performance. In this article, we’ll explore the key benefits and features of this advanced production line, highlighting why it is becoming a preferred choice for manufacturers.

One of the key advantages of the Feininger XPS Cornice Production Line is the production of low-density XPS foam. This type of foam is highly efficient for manufacturing decorative cornices, as it provides a perfect balance between lightness and strength. The low density of the foam makes it easier to handle and install, reducing transportation costs and making the cornices more accessible for various types of construction projects.

However, despite the lower density, the compressive strength of the foam remains high. This ensures that the final product is not only lightweight but also durable, able to withstand the pressures and demands of both residential and commercial applications. This feature makes it ideal for long-lasting installations where quality cannot be compromised.

Feininger’s XPS Cornice Production Line boasts a scientifically designed feed system that ensures an optimal flow of raw materials, facilitating consistent and precise output. The careful configuration of the system contributes to the efficient production process, ensuring that each batch of cornices meets the desired specifications without any inconsistencies.

Moreover, the temperature control of the foaming agent injection systems and heat exchangers is crucial for maintaining optimal conditions during production. These components work together to ensure that the foam achieves the perfect density and structure, resulting in a product that is both strong and lightweight.

An important feature of the Feininger XPS Cornice Production Line is its use of 100% CO2 foam. This sustainable foaming agent replaces harmful chemicals traditionally used in foam production, making the process more environmentally friendly. By utilizing CO2 as the foaming agent, the Feininger system helps reduce the carbon footprint of the production process, aligning with global efforts to adopt greener and more eco-conscious manufacturing practices.

This commitment to sustainability not only helps manufacturers meet increasingly stringent environmental regulations but also appeals to eco-conscious consumers and businesses looking for greener alternatives.

Energy consumption is a significant concern for many manufacturers, particularly in industries with high production volumes. The Feininger XPS Cornice Production Line is designed with a low power motor and gear system, optimizing the overall energy usage. The low energy consumption ensures that production costs are minimized while maintaining high output efficiency.

Additionally, the gearbox design ensures smooth and reliable operation with minimal wear and tear, extending the lifespan of the equipment and reducing maintenance costs over time.

Feininger offers not only advanced production equipment but also exceptional training and technical support. With their NingGe-extruded profile production experience, Feininger provides clients with free training and guidance on the proper setup and operation of the XPS Cornice Production Line. This support helps businesses avoid common pitfalls and operational mistakes, leading to a more seamless integration of the production line into existing manufacturing facilities.

Whether you are a new client or an experienced manufacturer, Feininger’s technical expertise ensures that you get the most out of the equipment, enabling you to maximize productivity and minimize downtime.

The Feininger XPS Cornice Production Line stands out in the market for its high compressive strength, reliable quality, low energy consumption, and sustainability. By choosing this advanced production line, manufacturers can ensure that they are providing top-notch, eco-friendly, and durable XPS foam cornices to meet the needs of their customers.

In addition to the technical benefits, Feininger’s commitment to customer satisfaction, support, and innovation makes them a trusted partner in the construction and foam manufacturing industries. With Feininger, you can be confident in the efficiency, sustainability, and quality of your production process.

The Feininger XPS Cornice Production Line offers a comprehensive solution for manufacturers looking to produce high-quality, durable, and environmentally friendly foam cornices. With its advanced features such as low-density XPS foam, sustainable CO2 foaming, scientific configuration, and low energy consumption, this production line is set to revolutionize the way cornices are made. By choosing Feininger as your supplier, you benefit from a state-of-the-art production process, expert guidance, and a commitment to sustainable manufacturing practices. Whether you’re looking to upgrade your production capacity or improve your environmental footprint, the Feininger XPS Cornice Production Line provides everything you need for success in today’s competitive market.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

07 Apr 2024

07 Apr 2024 Efficiency and Precision: Benefits of the Micro Supercritical CO₂&N₂ Injection Machine

In the realm of polymer processing and extrusion, the Micro Supercritical CO₂&N₂ Injection Machine from China Feininger has emerged as a game-changer, offering unparalleled efficiency, precision, and numerous benefits.

02 Jul 2024

02 Jul 2024 Revolutionizing Manufacturing: An Inside Look at the PET Foam Sheet Production Line

In the ever-evolving world of manufacturing, PET foam sheets have emerged as a versatile and essential material. From automotive to construction, these lightweight yet strong sheets are revolutionizing various industries.

14 Mar 2025

14 Mar 2025 Common Challenges in PS Skirting Production and How to Overcome Them

Polystyrene (PS) skirting boards have become a popular choice for interior and exterior decoration due to their lightweight nature, durability, and resistance to moisture. However, manufacturers often face several challenges in the production process, which can impact efficiency, quality, and sustainability.