Technology

14

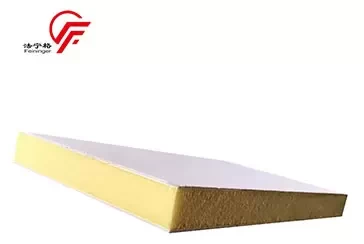

Mar . 2025Polystyrene (PS) skirting boards have become a popular choice for interior and exterior decoration due to their lightweight nature, durability, and resistance to moisture. However, manufacturers often face several challenges in the production process, which can impact efficiency, quality, and sustainability.

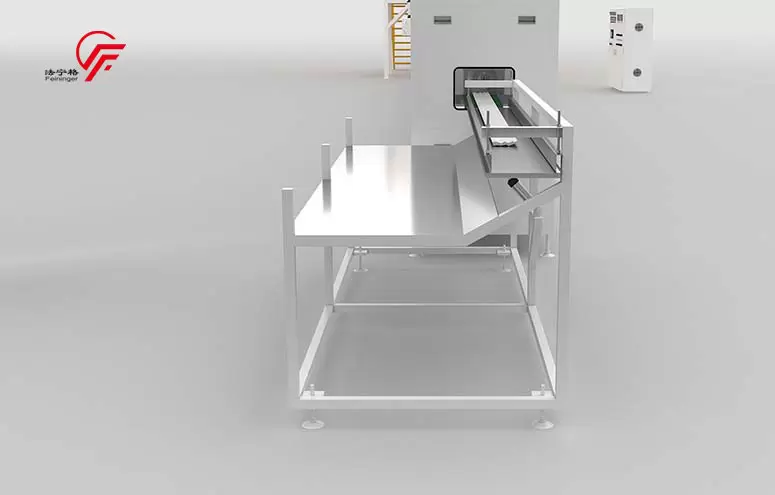

Feininger, a leading innovator in extrusion technology, has introduced a PS skirting production machine that leverages supercritical CO₂ physical foaming, setting it apart from traditional chemical foaming methods. This advancement not only improves product quality but also enhances environmental sustainability.

In this article, we will explore the common challenges in PS skirting production and how Feininger's advanced technology helps overcome them.

Traditional PS skirting production often relies on chemical foaming agents, which can lead to high material consumption and increased costs. Additionally, these chemical foaming processes may result in inconsistencies in product density, leading to material wastage.

Feininger’s supercritical CO₂ physical foaming technology significantly reduces product density while maintaining strength and durability. This not only lowers raw material consumption but also decreases production costs, making the process more efficient and cost-effective.

Traditional chemical foaming methods release volatile organic compounds (VOCs) and other harmful emissions, raising environmental concerns and potential regulatory restrictions. As sustainability becomes a top priority, manufacturers must find eco-friendly alternatives.

Feininger’s innovative PS skirting production machines use supercritical CO₂ as a physical foaming agent, eliminating the need for harmful chemical foaming agents. This results in a more environmentally friendly production process, helping manufacturers meet sustainability goals while reducing regulatory compliance risks.

In traditional PS skirting production, achieving a uniform structure and high-quality surface finish can be difficult. Issues such as uneven foaming, poor adhesion, and surface imperfections can affect the final product’s appeal and durability.

Feininger’s advanced extrusion technology ensures a more uniform cell structure in PS skirting boards. The use of supercritical CO₂ foaming provides a smooth, defect-free surface, improving the aesthetic appeal and performance of the skirting boards.

Manufacturers often need to produce a variety of decorative moldings, including picture frames, mirror frames, floor boards, ceiling corners, and wall panels. Traditional production methods may limit the ability to switch between different designs and applications efficiently.

Feininger’s PS skirting production line is designed to be highly adaptable, allowing for the production of multiple types of PS decorative materials. With customizable molds and automated controls, manufacturers can seamlessly adjust production to meet diverse market demands.

Traditional PS extrusion processes can be energy-intensive, increasing operational costs. Inefficient processing can also lead to excessive waste, further reducing profitability.

Feininger’s PS skirting machines incorporate energy-efficient extrusion technology with precise temperature control and optimized material flow. The use of supercritical CO₂ foaming reduces energy consumption and enhances overall production efficiency, leading to lower operational costs and higher output quality.

PS skirting boards need to maintain their structural integrity, especially when used in humid or high-traffic areas. Some traditionally produced skirting boards may suffer from warping, brittleness, or reduced lifespan.

Feininger’s PS skirting production process enhances material stability by ensuring a consistent foam structure with improved impact resistance. The supercritical CO₂ foaming method results in a lightweight yet durable product, capable of withstanding long-term use without deformation.

Feininger’s supercritical CO₂ foaming technology is a game-changer in the PS skirting industry, providing manufacturers with:

✅ Lower production costs – Reduced material usage and energy-efficient operation.

✅ Eco-friendly production – No harmful chemical foaming agents, reducing emissions.

✅ Superior product quality – Smooth surface finish, consistent structure, and improved durability.

✅ Versatile applications – Suitable for skirting boards, moldings, frames, and more.

✅ Increased efficiency – Advanced extrusion technology for optimized production.

By adopting Feininger’s advanced PS skirting production machines, manufacturers can enhance productivity, reduce costs, and meet the growing demand for eco-friendly building materials.

If you are looking for a high-performance and sustainable PS skirting production solution, Feininger is your trusted partner. Contact us today to learn more about how our supercritical CO₂ foaming technology can help transform your production process.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

13 Mar 2024

13 Mar 2024 The Advantages of Advanced EPP Beads Machines

In the world of protective packaging and lightweight construction materials, Expanded Polypropylene (EPP) beads stand out for their exceptional properties.

15 Dec 2023

15 Dec 2023 Congratulate! Chairman Guo Xinqi was hired as an expert in the "Expert Working Group of XPS Special Committee of China Plastics Association"

Warm congratulations to Guo Xinqi, Chairman of Nanjing Feininger Energy Saving Technology Co., Ltd., for being hired as an expert in the "Expert Working Group of the XPS Special Committee of China Plastics Association".

20 Nov 2023

20 Nov 2023 The manufacturing process of extruded panels

Although the production process of XPS type foam board is not complicated, we must pay close attention to all links in the process to ensure that the extruded board produced meets national and industry standards