Technology

18

Mar . 2025Polystyrene (PS) skirting boards and moldings have long been essential components in interior and exterior decoration, offering durability, aesthetic appeal, and versatility. However, traditional production methods often face challenges such as high material density, environmental concerns, and inefficient manufacturing processes.

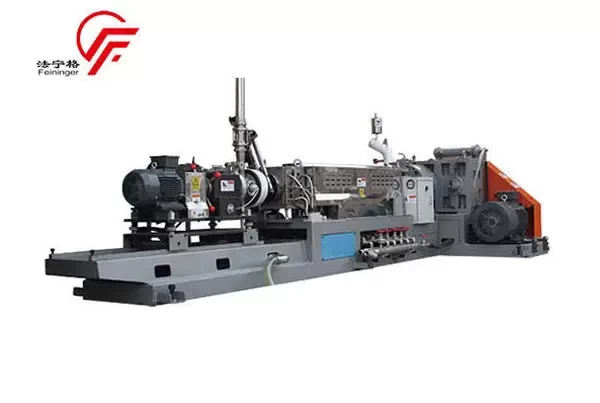

Feininger, a leader in extrusion technology, has introduced a revolutionary PS skirting production line that employs supercritical CO₂ physical foaming technology. This cutting-edge approach significantly reduces product density, enhances sustainability, and optimizes production efficiency—setting a new benchmark in decorative trim manufacturing.

Traditional PS skirting production relies on chemical foaming agents, which can lead to higher material usage, environmental concerns, and inconsistent product quality. Feininger's supercritical CO₂ physical foaming method eliminates these issues, offering manufacturers a superior solution with multiple advantages:

Lower Product Density – Reduces material consumption and cost

Eco-Friendly Process – Eliminates chemical foaming agents, reducing emissions

Consistent Quality – Produces a uniform structure with smooth surface finishes

Versatile Applications – Supports skirting boards, moldings, frames, and panels

Optimized Production Efficiency – Advanced extrusion process minimizes waste and energy consumption

With Feininger's PS skirting production machines, manufacturers can achieve superior product quality while ensuring cost-effectiveness and sustainability.

Feininger's PS skirting frame making machine follows a highly automated and precise manufacturing process, ensuring consistency and efficiency. Let's break down the key steps:

The production begins by adding raw materials in a specific ratio and pouring them into a mixer for uniform blending.

Unlike traditional chemical foaming methods that release harmful emissions, Feininger's supercritical CO₂ foaming technology is 100% eco-friendly. It eliminates chemical waste and VOC emissions, making it a greener choice for manufacturers.

By reducing product density, Feininger's technology lowers raw material consumption without compromising strength and durability. This translates into lower production costs and higher profitability for manufacturers.

Feininger’s PS skirting boards are ideal for high-end interior and exterior decoration, ensuring long-lasting performance.

The fully automated production line minimizes manual labor, reduces downtime, and optimizes extrusion speed—resulting in higher output and faster turnaround times.

Feininger's PS skirting manufacturing system is designed to produce a variety of decorative trim products, including:

These products are widely used in residential, commercial, and industrial applications, providing an elegant and functional finish to modern spaces.

As the industry shifts toward eco-friendly and cost-efficient solutions, Feininger's supercritical CO₂ foaming technology is paving the way for the next generation of PS skirting board production.

By integrating advanced extrusion techniques, automated precision, and environmental consciousness, Feininger is revolutionizing decorative trim manufacturing—offering manufacturers a competitive edge in the market.

Looking for a high-performance and sustainable PS skirting production solution? Feininger has you covered!

Contact us today to learn more about our cutting-edge PS skirting production machines and how they can enhance your manufacturing process.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

26 Dec 2024

26 Dec 2024 Exploring the Technology Behind PET Foam Core Production Lines

In recent years, PET foam cores have emerged as a highly popular material in industries ranging from aerospace to automotive, construction, and beyond. Known for their impressive strength-to-weight ratio, excellent durability, and eco-friendly properties, PET foam cores are manufactured using sophisticated technology in specialized production lines.

09 May 2024

09 May 2024 A Deep Dive into the Efficiency of CO2 XPS Production Lines

In the ever-evolving landscape of industrial manufacturing, the push towards more sustainable and efficient production methods has led to significant advancements in various technologies. One such innovation is the CO2 XPS production line.

23 Jul 2024

23 Jul 2024 Exploring the Benefits of TPU Underwater Pelletizers in Polymer Processing

In the dynamic world of polymer processing, efficiency and quality are paramount. Thermoplastic polyurethane (TPU) underwater pelletizers have emerged as essential tools in this industry, offering numerous advantages that enhance both production and product performance.