Technology

26

Dec . 2024In recent years, PET foam cores have emerged as a highly popular material in industries ranging from aerospace to automotive, construction, and beyond. Known for their impressive strength-to-weight ratio, excellent durability, and eco-friendly properties, PET foam cores are manufactured using sophisticated technology in specialized production lines. In this blog post, we will explore the advanced technology behind PET Foam Core Production Lines and how it enables the production of these high-performance materials.

PET (Polyethylene Terephthalate) foam cores are lightweight materials made by expanding PET resin with blowing agents. They are highly valued for their strength, low density, and ability to withstand moisture, chemicals, and high temperatures. These properties make PET foam cores ideal for use in industries such as construction, automotive, aerospace, and wind energy, where lightweight and strong materials are crucial.

The technology behind PET Foam Core Production Lines is designed to meet the growing demand for high-quality, cost-effective, and sustainable materials. The production process typically involves several key stages: extrusion, foaming, cooling, cutting, and quality control. Let's break down each step in the production line and explore the role of technology at each stage.

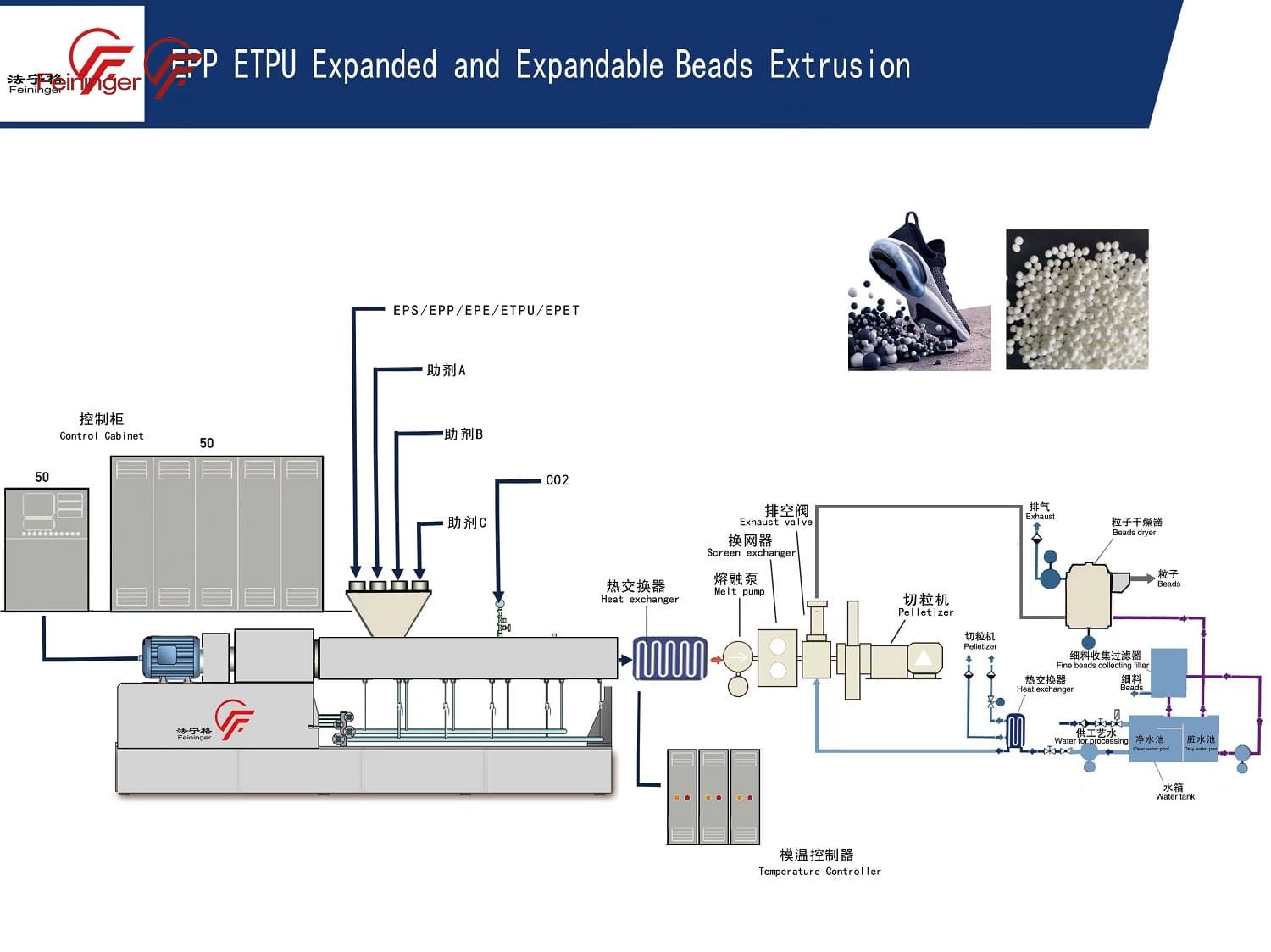

The first stage in the PET Foam Core Production Lines is extrusion, where the raw PET material is mixed with blowing agents and other additives. This mixture is then melted and forced through an extruder, which shapes it into a continuous foam sheet.

Once the material is extruded, the next crucial step is the foaming process, where the PET material begins to expand and form its cellular structure. This is achieved by the chemical reaction between the PET resin and the blowing agents.

After the foam is extruded and foamed, it needs to be cooled to solidify the structure. Cooling is a critical step to ensure the foam retains its properties and doesn't deform after production.

Once the foam has cooled and solidified, it is ready for cutting and shaping. At this stage, the continuous foam sheet is cut into specific sizes or shapes based on customer requirements. This could range from large sheets to small blocks or specific geometric shapes used in applications such as sandwich panels or composite materials.

After the foam has been cut and shaped, it goes through a post-processing phase, which may include surface treatment, additional drying, or coating to enhance the foam's properties. For example, some PET foam cores may undergo UV treatment to improve their resistance to environmental conditions.

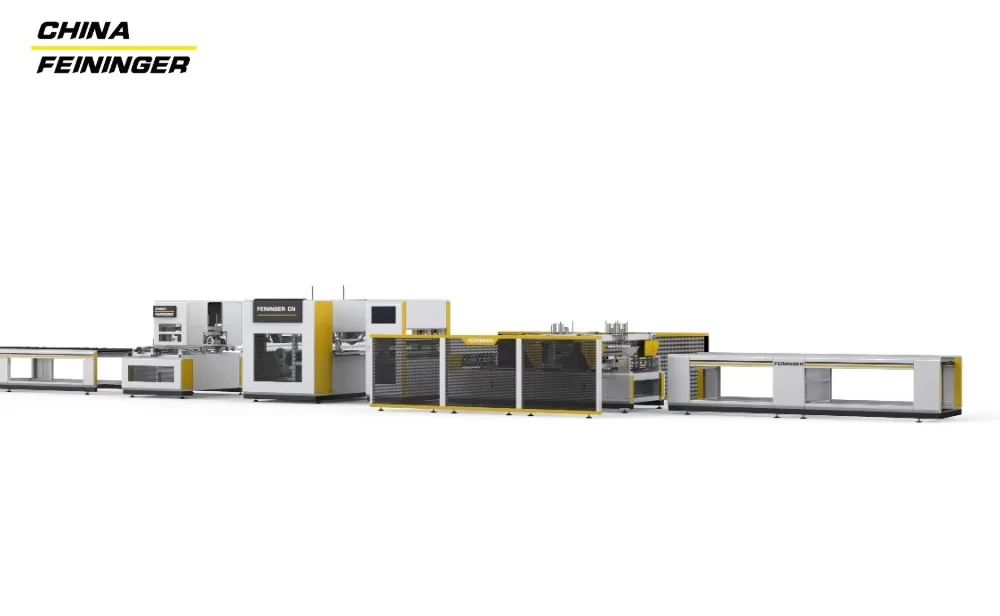

The technology behind PET Foam Core Production Lines plays a pivotal role in producing high-quality, sustainable, and versatile foam materials. By using advanced extrusion, foaming, cooling, and cutting technologies, manufacturers like China Feininger are able to produce foam cores that meet the stringent requirements of industries like aerospace, automotive, and construction.

As the demand for lightweight, strong, and eco-friendly materials continues to rise, the PET Foam Core Production Line technology will undoubtedly continue to evolve, helping industries meet sustainability goals while maintaining high standards of performance and efficiency.

If you're looking for a reliable manufacturer of PET foam core materials or need a custom PET Foam Core Production Line, China Feininger is a trusted name in the industry. They offer state-of-the-art technology and high-quality products to meet the needs of modern manufacturing.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

13 Jun 2025

13 Jun 2025 Key Tips for Exporters Buying XPS Foam Lines from China

As global demand for energy-efficient and eco-friendly building materials rises, XPS foam insulation boards have become essential in both residential and commercial construction.

26 Sep 2023

26 Sep 2023 Feininger and Western University jointly developed a one-step method to produce ETPU "popcorn", which is a boon to the industry

ETPU, or foamed TPU, commonly known as "popcorn", is currently the most elastic foam particle on the market. After pressure, heating and foaming treatment, the TPU particle volume will increase by 10 times, forming a honeycomb of non-crosslinked foam particles containing tiny closed bubbles, called ETPU.

15 Jul 2025

15 Jul 2025 How to Choose an XPS Extrusion Line: A Comprehensive Guide

Selecting the right XPS (Extruded Polystyrene) extrusion line is critical for producing high-quality insulation boards that meet market demands and regulatory requirements.