Technology

23

Jul . 2024In the dynamic world of polymer processing, efficiency and quality are paramount. Thermoplastic polyurethane (TPU) underwater pelletizers have emerged as essential tools in this industry, offering numerous advantages that enhance both production and product performance. As a leading TPU underwater pelletizer manufacturer based in China, Feininger specializes in advanced polymer processing equipment designed to optimize efficiency and product quality. This article explores the benefits of TPU underwater pelletizers in polymer processing and how Feininger's cutting-edge technology meets the diverse needs of polymer manufacturers worldwide.

TPU underwater pelletizers are specialized machines used to convert molten TPU into uniform pellets by cutting the polymer strands while submerged in water. This process not only cools the pellets instantly but also ensures consistent size and quality. Feininger’s TPU underwater pelletizer systems are engineered with state-of-the-art technology to provide reliable, efficient, and high-quality pellet production.

One of the primary advantages of TPU underwater pelletizers is their ability to cool the pellets instantly. The submersion in water rapidly dissipates heat, solidifying the pellets quickly and uniformly.

Feininger’s TPU underwater pelletizers are designed to produce pellets of uniform size and shape. The precise cutting mechanism and stable operating conditions contribute to consistent pellet quality.

The efficient cooling and cutting mechanisms of TPU underwater pelletizers minimize process interruptions and reduce downtime.

Underwater pelletizing significantly reduces the generation of dust compared to other pelletizing methods. This leads to a cleaner production environment and reduces the need for additional dust control measures.

Feininger’s TPU underwater pelletizers are designed to be energy-efficient. The advanced thermal management systems and optimized process controls reduce energy consumption during pellet production.

TPU pellets are widely used in the automotive industry for manufacturing various components such as seals, gaskets, and interior trims. The material’s flexibility, durability, and resistance to wear make it ideal for these applications.

In the footwear industry, TPU pellets are used to produce soles and other components. The material’s excellent abrasion resistance and comfort properties are highly valued in this sector.

TPU is also used in the medical field for making flexible tubing, catheters, and other medical devices. The biocompatibility and flexibility of TPU make it suitable for medical applications.

In consumer electronics, TPU is used for protective cases, cable jackets, and other components that require flexibility and durability.

Feininger integrates advanced technology into its TPU underwater pelletizer systems to ensure optimal performance and reliability. The innovative design and precision engineering of Feininger's equipment cater to the evolving needs of the polymer processing industry.

As a leading manufacturer based in China, Feininger serves polymer manufacturers worldwide, providing comprehensive support and customized solutions to meet diverse production requirements. Our commitment to quality and customer satisfaction drives us to continuously innovate and improve our products.

TPU underwater pelletizers play a crucial role in enhancing the efficiency and quality of polymer processing. Feininger’s advanced pelletizer systems offer significant benefits, including enhanced cooling efficiency, uniform pellet quality, improved process efficiency, dust-free operation, and energy efficiency. These advantages make Feininger’s TPU underwater pelletizers an excellent choice for polymer manufacturers seeking to optimize their production processes.

For more information on how Feininger’s TPU underwater pelletizer systems can benefit your polymer processing operations, please contact us or visit our website. Experience the cutting-edge technology and superior performance that Feininger brings to the world of polymer processing.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

27 Nov 2024

27 Nov 2024 Why XPS Extruded Board is the Ideal Cold Storage Insulation Solution

In cold storage construction, the choice of insulation material is crucial. The performance and longevity of the storage facility depend on the insulation's ability to maintain excellent thermal resistance and withstand high humidity environments over the long term.

26 Sep 2023

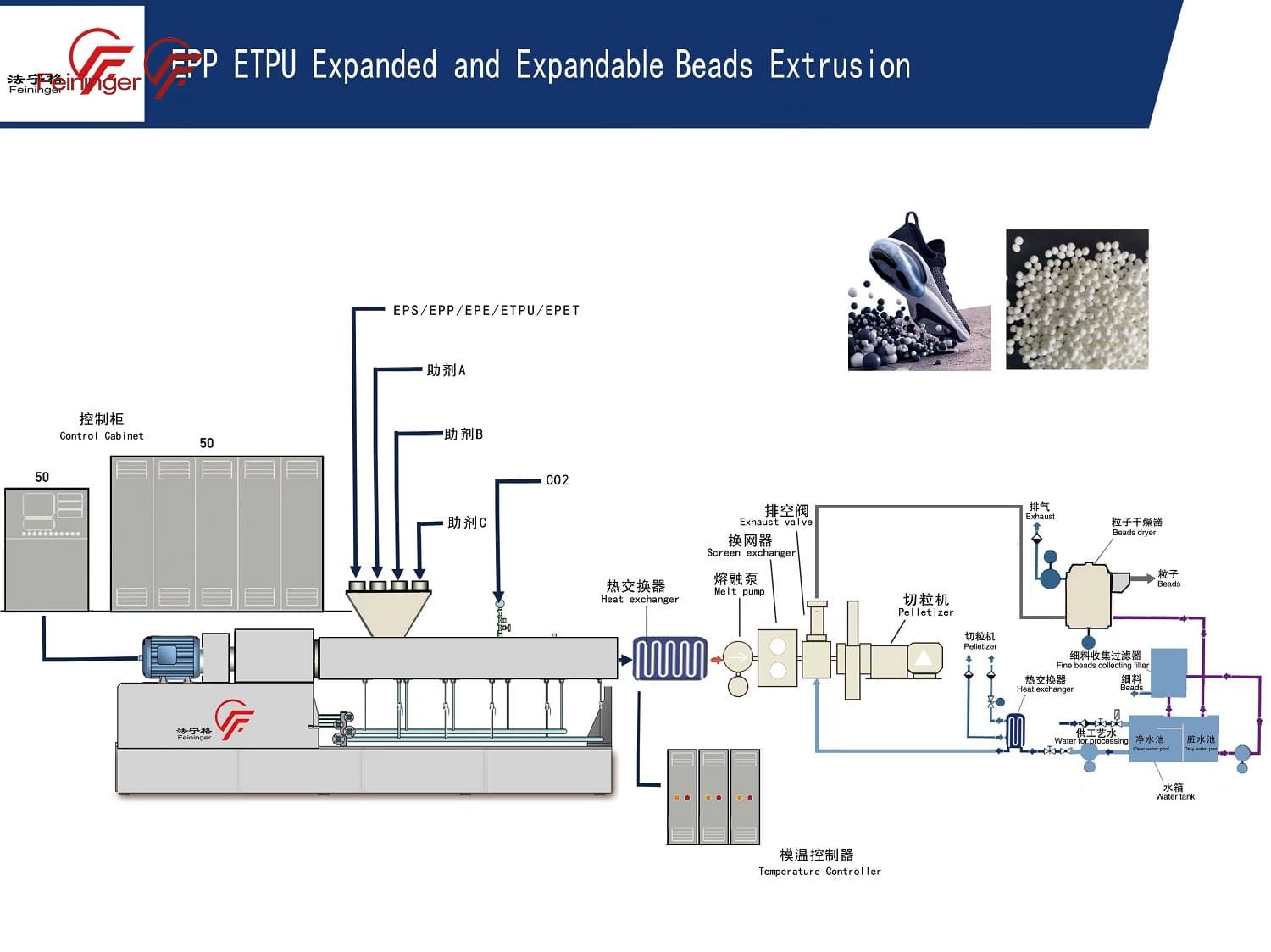

26 Sep 2023 Feininger and Western University jointly developed a one-step method to produce ETPU "popcorn", which is a boon to the industry

ETPU, or foamed TPU, commonly known as "popcorn", is currently the most elastic foam particle on the market. After pressure, heating and foaming treatment, the TPU particle volume will increase by 10 times, forming a honeycomb of non-crosslinked foam particles containing tiny closed bubbles, called ETPU.

09 Apr 2024

09 Apr 2024 China Feininger to Showcase Innovative XPS Foam Solutions at the 135th China Import and Export Fair

China Feininger, the pioneering manufacturer of XPS Extrusion Line and XPS Foam Board in China, is gearing up to participate in the prestigious 135th China Import and Export Fair.