Technology

26

Sep . 2023ETPU, or foamed TPU, commonly known as "popcorn", is currently the most elastic foam particle on the market.

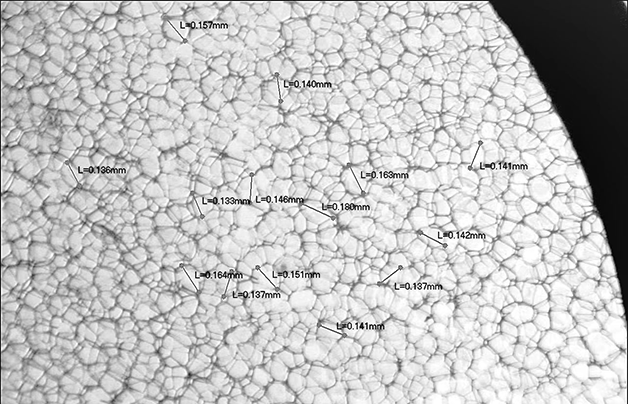

After pressure, heating and foaming treatment, the TPU particle volume will increase by 10 times, forming a honeycomb of non-crosslinked foam particles containing tiny closed bubbles, called ETPU.

Due to its excellent recovery performance, the product is widely used in high-end sports equipment, automobiles, health care and other fields, and greatly improves the comfort of human movement and riding through bionics, and has broad market prospects.

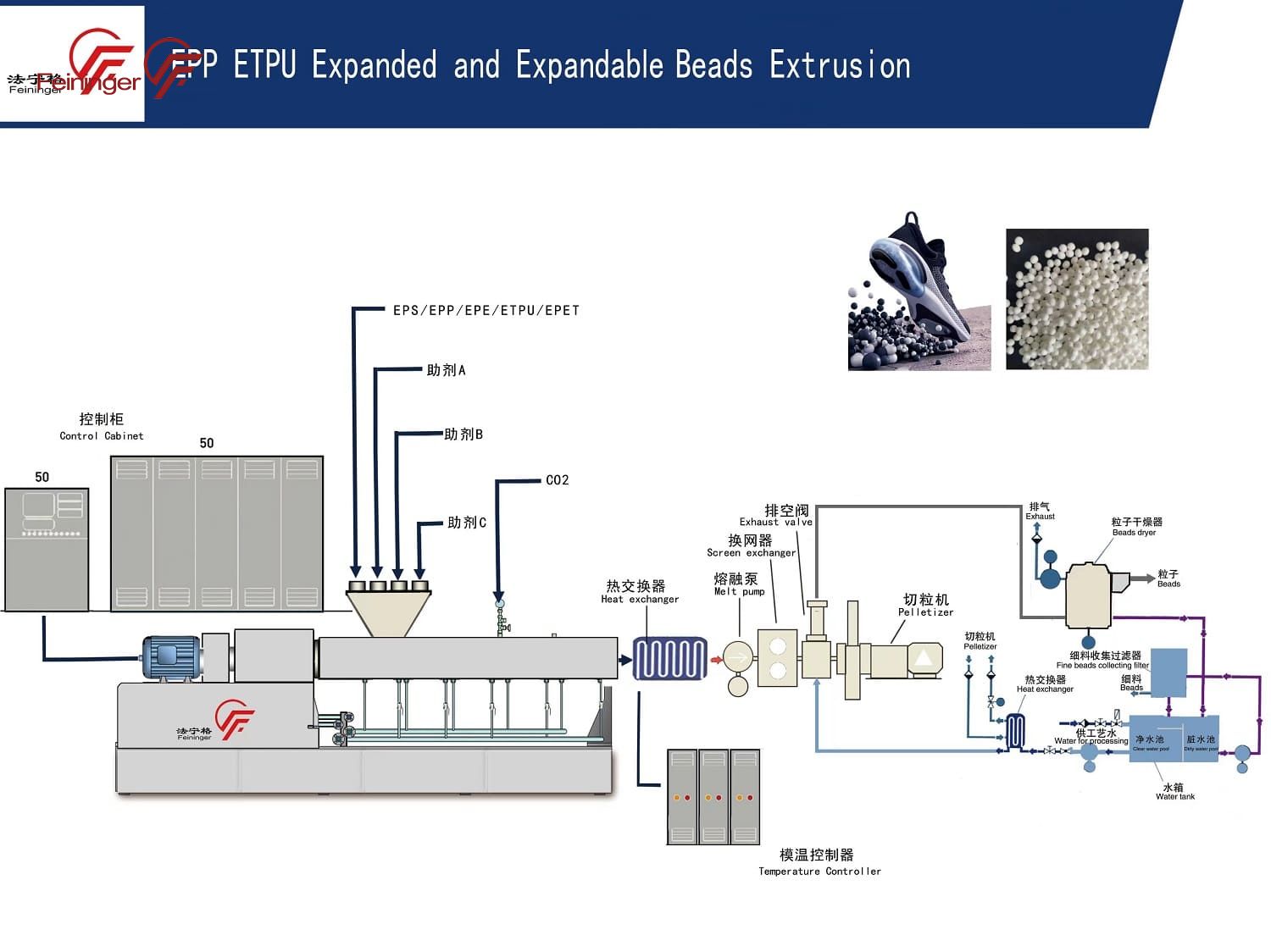

Feininger and Western University in Canada have jointly developed and successfully developed a one-step process to produce ETPU. One-step production of ETPU has high efficiency, fewer production steps, less personnel, high degree of automation, and this method is safe and environmentally friendly. And this technology has low cost, less investment, and is sought after by the majority of production enterprises, but because of the technical difficulty, it has been a pain point in the industry.

With the help of the international scientific research cooperation platform with Western University, Faninger successfully broke the "foreign monopoly" of ETPU production by BASF, a global industrial giant, and became the pioneer of domestic enterprises in the production of ETPU.

Compared with the ETPU produced by the traditional domestic pressure method, the ETPU produced by the one-step method has the advantages of light weight, excellent elasticity and shock absorption.

The sole made of ETPU not only has excellent elasticity, but also provides springback effect and buffering performance, which can effectively absorb the impact on the foot during running, provide good shock absorption effect for the foot, and effectively improve the safety of sports.

At the same time, the high rebound effect of ETPU material can feedback a lot of energy, which brings a good experience for runners."

ETPU new materials, has been widely used in puma, Jordan, Nike and other domestic and foreign high-end sports brands, can create great wealth for our country and enterprises every year. For the development of national industry, Feininger one-step extrusion production ETPU foaming technology is bound to bring major changes to the industry, we will wait and see.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

12 Jul 2023

12 Jul 2023 Advantages of feininger ETPU foamed particles

Feininger has been committed to the research of supercritical CO2 foaming equipment, using CO2 in supercritical state as a physical foaming agent applied to foam extrusion process, can produce microporous plastics with small and dense pores and improved mechanical properties, while achieving energy saving and consumption reduction. Feininger supercritical CO2 extrusion foam ETPU has the advantages of high rate and high resilience.

14 Mar 2025

14 Mar 2025 Common Challenges in PS Skirting Production and How to Overcome Them

Polystyrene (PS) skirting boards have become a popular choice for interior and exterior decoration due to their lightweight nature, durability, and resistance to moisture. However, manufacturers often face several challenges in the production process, which can impact efficiency, quality, and sustainability.

12 Dec 2024

12 Dec 2024 PS Skirting Boards vs. Traditional Wood: Which is Right for Your Project?

When it comes to finishing touches in interior design, skirting boards (also known as baseboards) play a critical role. They are not only decorative but also protect walls from scuffs, dirt, and impact, while creating a clean and polished look.