Technology

02

Jul . 2024In the ever-evolving world of manufacturing, PET foam sheets have emerged as a versatile and essential material. From automotive to construction, these lightweight yet strong sheets are revolutionizing various industries. Leading this transformation is the Feininger PET sheet extrusion line, which embodies the pinnacle of innovation and efficiency. This article delves into the intricacies of PET foam sheet production, highlighting the processes, technological advancements, applications, challenges, regulatory considerations, and future outlook.

PET (Polyethylene Terephthalate) foam sheets are lightweight, durable materials known for their high strength-to-weight ratio, thermal insulation properties, and chemical resistance. They are widely used in industries such as automotive, construction, packaging, and more. Their versatility and robustness make them ideal for applications ranging from lightweight structural components to insulation panels.

The production of PET foam sheets involves several critical steps:

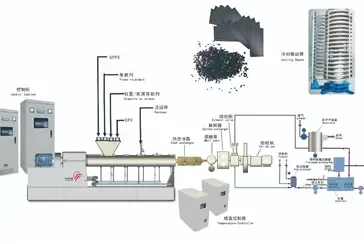

The Feininger PET sheet extrusion line is equipped with state-of-the-art machinery designed for precision and efficiency. Key components include:

Quality control is integral to the production process. The Feininger PET sheet extrusion line employs rigorous testing protocols, including:

Recent technological advancements have significantly enhanced the production of PET foam sheets. Innovations include improved foaming agents, advanced extrusion techniques, and better material formulations that enhance the mechanical properties of the foam sheets.

Modern production lines, like those from Feininger, incorporate AI and IoT technologies. These advancements enable real-time monitoring and control, optimizing production efficiency and reducing waste.

Traditional methods relied heavily on manual processes, leading to inconsistencies and lower efficiency. In contrast, modern production lines utilize automation and precision engineering, resulting in higher quality, consistency, and throughput.

PET foam sheets are integral to several industries:

The market for PET foam sheets is growing, driven by increasing demand for lightweight, durable materials. Future trends indicate a surge in applications within the green building sector and electric vehicles, emphasizing sustainability and efficiency.

Production lines like Feininger’s are continually evolving, integrating new technologies and materials to meet changing market demands. This includes developing eco-friendly products and enhancing production capabilities.

Challenges in PET foam sheet production include ensuring uniform foam density, maintaining dimensional stability, and minimizing production waste.

Feininger addresses these challenges through continuous R&D, implementing advanced foaming technologies, and employing precision engineering to achieve consistent quality.

Future challenges include adapting to stricter environmental regulations and increasing raw material costs. The industry is preparing by investing in sustainable practices and developing recyclable and biodegradable foam sheets.

PET foam sheet production must comply with various international standards and regulations regarding safety, environmental impact, and quality.

Ensuring worker safety and product quality involves stringent protocols, including regular equipment maintenance, safety training, and adherence to best practices in manufacturing.

Feininger’s production lines are designed to meet and exceed regulatory requirements, focusing on reducing emissions, recycling waste, and ensuring safe working conditions.

The future of PET foam sheet production looks promising, with advancements in materials science and manufacturing technologies driving growth.

Anticipated advancements include the development of more sustainable materials, enhanced automation, and the integration of AI for predictive maintenance and process optimization.

PET foam sheets will play a crucial role in the future of manufacturing, particularly in sectors focusing on lightweight, high-strength, and sustainable materials.

The Feininger PET sheet extrusion line is revolutionizing the manufacturing of PET foam sheets, providing a blend of innovation, efficiency, and quality. As industries continue to evolve, the role of advanced production lines in meeting future demands and overcoming challenges will be critical. With a commitment to excellence and continuous improvement, Feininger is at the forefront of this transformation, shaping the future of PET foam sheet production.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

11 Apr 2025

11 Apr 2025 Advanced Technology in EPS Beads Foam Production: A Look at Feininger’s Cutting-Edge Solutions

In the world of foam production, particularly EPS (Expanded Polystyrene), technology plays a crucial role in determining product quality, operational efficiency, and overall cost-effectiveness.

23 Oct 2024

23 Oct 2024 Choosing the Right Foam Sheet Laboratory Machine: A Guide for Manufacturers

Selecting the right foam sheet laboratory machine is crucial for manufacturers aiming to produce high-quality, consistent, and innovative foam products. The right machine empowers businesses to experiment with new materials, achieve desired foam densities, and maintain stringent quality standards.

10 Apr 2024

10 Apr 2024 China Feininger to Showcase Cutting-Edge XPS Foam Solutions at Chinaplas 2024

China Feininger, the pioneer in XPS Foam technology and equipment manufacturing, is set to participate in the prestigious Chinaplas 2024, the 36th China International Plastics and Rubber Industry Exhibition.