Technology

27

Jun . 2024In the realm of polymer processing, selecting the appropriate equipment can significantly impact efficiency, product quality, and overall operational costs. When it comes to TPU (Thermoplastic Polyurethane) underwater pelletizers, making an informed decision is crucial to meeting production goals effectively.

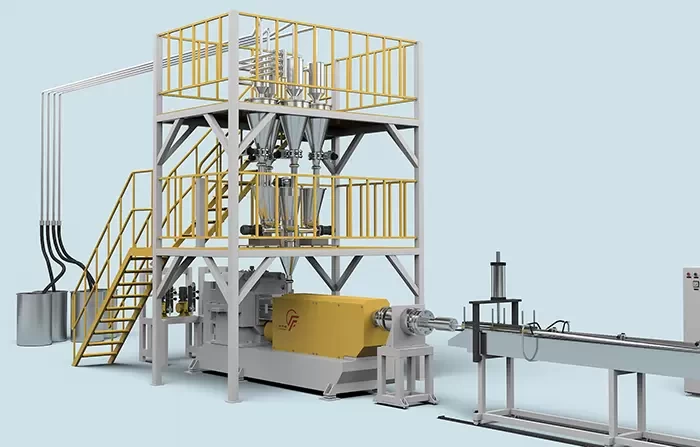

The TPU underwater pelletizer system manufactured by China Feininger is designed with advanced technology to optimize the granulation process. At its core, the system's main machine is the extruder system, comprising the extrusion system, transmission system, and heating and cooling system.

Extrusion System: This includes essential components such as the screw, barrel, hopper, head, and die. The extrusion system plays a pivotal role in heating and molding the plastic material into a consistent melt. The material is then continuously extruded through the die under controlled pressure, ensuring uniform pellet formation.

Thermal Relative Edge Formwork Technology: Unique to China Feininger's design, this technology maintains a constant temperature in the material carrier, preventing melt condensation in the die holes. This feature enhances process reliability and efficiency, minimizing downtime and ensuring consistent product quality.

Efficient Water Treatment and Drying Systems: The system is equipped with advanced water treatment and drying technologies that operate efficiently, ensuring continuous filtration of process water and reducing maintenance costs.

Production Flexibility: Designed for versatility, the system can easily adapt to different production requirements and polymer types. This flexibility enhances operational efficiency and allows for seamless transitions between different production runs.

Automatic Operation and Ease of Use: The TPU underwater pelletizer enables automatic granulation, simplifying operation and minimizing labor requirements. It offers precise control over the granulation process, resulting in high-quality pellets suitable for various applications.

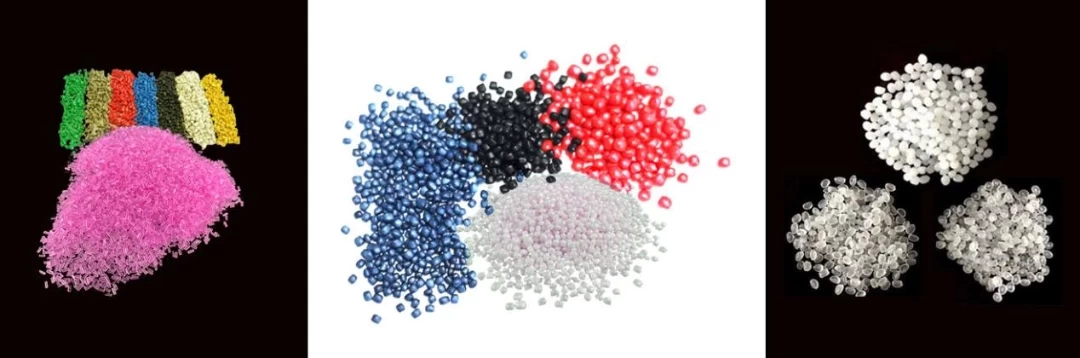

Energy Efficiency and Cost Savings: Compared to traditional strip granulation methods, the underwater pelletization process consumes less energy and reduces production costs. This advantage is particularly significant for low viscosity or adhesive polymers like TPU, PP, PE, PS, TPE, as well as for masterbatch filling and chemical raw materials.

Enhanced Product Quality: The system ensures good particle quality with consistent size and shape, meeting stringent manufacturing standards and customer specifications.

Choosing the right TPU underwater pelletizer involves evaluating factors such as production requirements, polymer characteristics, operational efficiency, and cost-effectiveness. China Feininger's advanced technologies and design innovations make their TPU underwater pelletizers a compelling choice for manufacturers seeking reliable performance, superior product quality, and operational flexibility.

By selecting a TPU underwater pelletizer from China Feininger, manufacturers can enhance their production capabilities, reduce operational costs, and achieve consistent, high-quality pellet outputs tailored to diverse industry needs.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

07 Apr 2024

07 Apr 2024 Efficiency and Precision: Benefits of the Micro Supercritical CO₂&N₂ Injection Machine

In the realm of polymer processing and extrusion, the Micro Supercritical CO₂&N₂ Injection Machine from China Feininger has emerged as a game-changer, offering unparalleled efficiency, precision, and numerous benefits.

28 Feb 2025

28 Feb 2025 Exploring the XPS Cornice Production Line: Key Benefits and Features

In the ever-evolving world of construction and architectural design, XPS (extruded polystyrene) foam is rapidly gaining popularity as a versatile material for moldings and decorative elements.

29 Dec 2023

29 Dec 2023 The difference between EPP and ordinary foam

In the realm of foam plastics, two contenders stand out with distinct compositions, uses, and environmental impacts. Expanded Polypropylene (EPP) foam and ordinary Expanded Polystyrene (EPS) foam cater to diverse applications