Technology

11

Apr . 2025In the world of foam production, particularly EPS (Expanded Polystyrene), technology plays a crucial role in determining product quality, operational efficiency, and overall cost-effectiveness. As industries continue to demand higher standards in terms of performance and output, companies like Feininger have risen to the challenge by integrating cutting-edge technologies and innovative solutions into their graphite EPS production line. In this article, we will explore how Feininger's advancements in extruder design, uniform temperature heat exchangers, and precise extrusion methods are transforming EPS beads foam production.

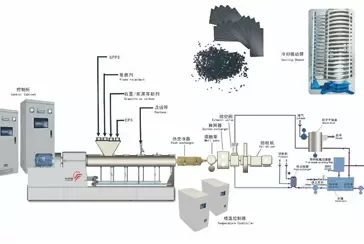

Feininger's new graphite EPS raw material production line is designed with scientific principles in mind, allowing for exceptional precision and efficiency. One of the standout features of this production line is its extruder design. Feininger employs a parallel twin-screw system, which is recognized for its ability to create uniform pressure and temperature distribution during extrusion. This technology helps avoid common production issues, such as blockage of the discharge holes, which is critical for maintaining consistent product quality.

Through this advanced design, Feininger ensures that the finished products—graphite EPS beads—meet high standards of quality. The uniformity of the temperature within the heat exchanger prevents the material from overheating or cooling unevenly, which could compromise the integrity of the foam. The result? EPS beads with excellent, consistent properties and a superior finished look that can meet the demands of various industries, from construction to packaging.

In the production of thermoplastic foam particles, extrusion under water is a key step that requires high water pressure. Feininger’s approach to managing this process stands out thanks to its scientifically designed water temperature and water pressure system. This precision ensures that the foam beads are shaped and expanded correctly, reducing the likelihood of defects and maximizing production efficiency.

One of the significant challenges in foam production is ensuring that the discharge hole remains unobstructed during extrusion. Feininger’s innovative design addresses this by maintaining an optimal balance between temperature, pressure, and material flow. This reduces the risk of material blockages and allows for smoother operation with fewer interruptions, ultimately improving the overall output of the production line.

Once the EPS beads have been extruded, the next step is to ensure that they are properly dried and cooled. Feininger’s advanced production line utilizes centrifugal drying, which helps remove excess moisture from the foam beads. After drying, the beads undergo a vibration cooling process, which is crucial for ensuring they reach the desired consistency and texture.

Feininger's bottom-up vibration design is particularly effective in ensuring that cooling is more uniform, leading to better results. This design ensures that the cooling process is optimized for the beads' size and structure, preventing potential defects caused by uneven cooling. The result is a higher-quality product that meets the strictest standards in the industry.

What truly sets Feininger apart is its rich production experience in the field of graphite EPS. Feininger's team of experts has years of experience working with cutting-edge foam production technology, which means they are well-versed in both the technical and operational challenges that may arise during production. To further enhance customer satisfaction, Feininger offers free technical training to customers, ensuring that they understand the full capabilities of their equipment and how to operate it for maximum efficiency.

The company's approach doesn't stop at equipment sales. Feininger is dedicated to providing effective and stable operation for its customers. Their equipment is designed to minimize the need for time-consuming adjustments and costly maintenance, helping customers get the most out of their investment without the hassle of frequent troubleshooting.

Feininger's graphite EPS production line delivers many advantages to customers, including:

High-quality EPS beads with uniform characteristics, thanks to advanced extruder and heat exchanger designs.

Efficient production processes, with scientifically controlled water pressure and temperature that prevent common issues such as blockages.

Optimized drying and cooling processes, ensuring the consistency and quality of the foam beads.

Comprehensive customer support, including free technical training and guidance to help customers get the most out of their equipment.

With Feininger's innovative technology, customers can expect greater benefits from their graphite EPS production lines, including improved operational efficiency and a higher return on investment. Feininger's equipment enables smoother production, consistent output, and reliable performance, all while reducing the need for constant adjustments or maintenance.

Feininger's advanced graphite EPS production line stands as a testament to the power of scientific design and innovative technology in the field of foam production. By integrating parallel twin-screw extruders, precise water temperature and pressure control, and optimized cooling techniques, Feininger offers a comprehensive solution that significantly improves the production process, product quality, and operational efficiency.

Whether you're looking to upgrade your existing production line or start a new venture in EPS production, Feininger's technology and expertise can provide the tools you need to succeed. Contact Feininger today to learn more about how their cutting-edge solutions can revolutionize your foam production operations.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

17 Apr 2024

17 Apr 2024 Enhancing Product Quality: Applications of the Micro Supercritical CO₂&N₂ Injection Machine

In the realm of polymer processing and manufacturing, the Micro Supercritical CO₂&N₂ Injection Machine from China Feininger has revolutionized the industry with its ability to enhance product quality across various applications.

14 Mar 2025

14 Mar 2025 Common Challenges in PS Skirting Production and How to Overcome Them

Polystyrene (PS) skirting boards have become a popular choice for interior and exterior decoration due to their lightweight nature, durability, and resistance to moisture. However, manufacturers often face several challenges in the production process, which can impact efficiency, quality, and sustainability.

21 Jun 2024

21 Jun 2024 The Future of Building Insulation: Trends and Innovations in XPS Foam Board with Aluminum Foil

As we move further into the 21st century, the demand for more efficient, sustainable building materials is on the rise. One of the standout products in this evolution is the XPS (Extruded Polystyrene) Foam Board with Aluminum Foil.