Technology

02

Apr . 2025In the rapidly evolving world of foam manufacturing, efficiency, durability, and sustainability are key drivers of success. One material that has been making waves due to its superior properties is ETPU foam (Ethylene Tetra-Polyurethane), which has found applications in a variety of industries, from cushioning products to automotive parts. Central to the production of ETPU foam is the ETPU Beads Foam Production Line, a sophisticated system that integrates cutting-edge technology to ensure the highest levels of performance and quality. In this blog, we'll explore the key features and innovations that are transforming modern foam manufacturing, with a focus on the advanced technology provided by Feininger, a leader in extrusion systems for ETPU production.

ETPU foam is a high-performance material known for its excellent elasticity, durability, and resistance to environmental factors. It is widely used in the production of cushioning materials, sports shoes, and protective packaging. The foam is created by using ETPU beads that are expanded and fused together to form a stable, resilient foam structure.

However, the production process of ETPU foam presents certain challenges, especially regarding the material's tendency to hydrolyze (break down due to moisture) and yellowing over time. These issues have historically posed problems in the application stage, particularly in industries where product aesthetics and longevity are crucial.

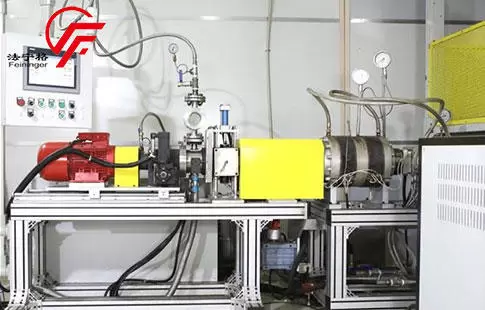

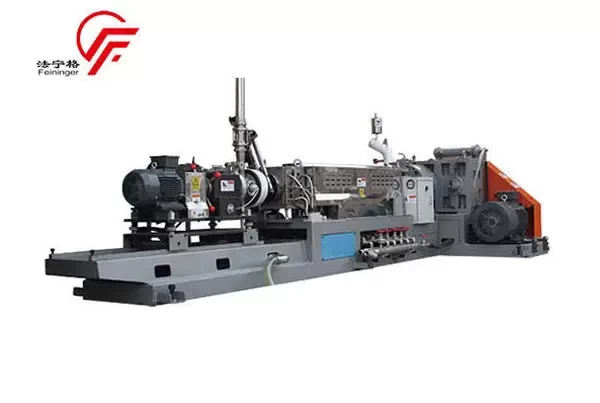

Feininger is at the forefront of ETPU foam production with its state-of-the-art ETPU Beads Foam Production Line. Known for its mature processes and high equipment stability, Feininger has developed a system that overcomes the common challenges faced by manufacturers in producing high-quality ETPU foam. The company’s innovative approach combines traditional extrusion technology with advanced scientific solutions.

One of the standout innovations in Feininger's ETPU production line is the use of supercritical CO2 fluid kettle pressure foaming. In this process, carbon dioxide (CO2) is used as a blowing agent, replacing traditional chemical foaming agents. This technique has several advantages:

Environmentally Friendly: Using CO2 as a foaming agent reduces the reliance on hazardous chemicals, making the production process more sustainable and eco-friendly.

Improved Foam Quality: Supercritical CO2 foaming leads to more uniform and controlled bead expansion, producing high-quality, consistent foam with better physical properties.

Energy Efficiency: This technology operates at lower temperatures compared to traditional methods, resulting in energy savings and faster production cycles.

Feininger's production line also incorporates pressure compensation technology, which addresses a critical issue in ETPU foam manufacturing: the hydrolysis and yellowing of polyester-based ETPU during the application phase.

Hydrolysis Prevention: Polyester-based ETPU is prone to absorbing moisture from the environment, which can lead to premature degradation of the foam. The pressure compensation technology regulates the internal pressure of the foam during production, preventing moisture absorption and significantly extending the foam’s longevity.

Enhanced Aesthetic Appeal: By preventing yellowing, the foam maintains its original color and aesthetic quality, which is essential for products like footwear and high-end packaging.

Stable Foam Properties: Pressure compensation ensures the foam retains its excellent mechanical properties over time, such as resilience, elasticity, and cushioning performance.

These technological innovations not only improve the quality of the foam but also enhance the overall production process, making it more efficient, sustainable, and cost-effective.

Let's break down some of the key features that make Feininger’s ETPU Beads Foam Production Line a game-changer in the foam manufacturing industry:

Feininger's ETPU production line is designed with high equipment stability in mind. The precision engineering of the equipment ensures consistent and reliable output, minimizing downtime and reducing maintenance costs. This stability is crucial for manufacturers who rely on high-volume production to meet market demands.

With years of expertise in extrusion technology, Feininger has developed a mature process that optimizes every step of ETPU foam production. From bead expansion to the final extrusion, the process is fine-tuned to ensure the best possible results. This allows manufacturers to produce foam that meets industry standards for performance and appearance.

Feininger is committed to sustainability, and the supercritical CO2 foaming technology is a testament to this. By reducing the environmental impact of the production process, Feininger ensures that the production of ETPU foam is as eco-friendly as possible without compromising on quality or performance.

Feininger offers customizable production lines that can be tailored to meet the specific needs of different industries. Whether it's for high-end footwear, automotive applications, or packaging, Feininger's ETPU Beads Foam Production Line can be adjusted to produce foam with varying densities, sizes, and properties.

Superior Foam Quality: The use of advanced technologies ensures that the produced foam has excellent resilience, elasticity, and long-lasting performance.

Cost Efficiency: With its energy-efficient and sustainable production methods, Feininger helps manufacturers lower operational costs while producing high-quality foam.

Customization: The ability to adjust production parameters means that the foam can be tailored to meet the specific requirements of different applications, offering greater flexibility in the marketplace.

Improved Product Longevity: The innovative pressure compensation technology addresses issues like hydrolysis and yellowing, ensuring that the foam maintains its quality over time.

Feininger's ETPU Beads Foam Production Line represents the cutting edge of modern foam manufacturing. By combining supercritical CO2 fluid kettle pressure foaming with pressure compensation technology, Feininger has solved long-standing challenges related to the degradation of polyester-based ETPU, while also improving foam quality, energy efficiency, and sustainability.

For manufacturers looking to stay ahead of the curve in the highly competitive foam production industry, Feininger offers a solution that not only delivers superior foam but also ensures a more eco-friendly, cost-effective, and high-performance production process. Whether for footwear, packaging, or automotive applications, Feininger’s ETPU production line is the perfect choice for businesses seeking reliability, innovation, and quality.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

27 Jun 2024

27 Jun 2024 Choosing the Right TPU Underwater Pelletizer for Your Manufacturing Needs

In the realm of polymer processing, selecting the appropriate equipment can significantly impact efficiency, product quality, and overall operational costs. When it comes to TPU (Thermoplastic Polyurethane) underwater pelletizers, making an informed decision is crucial to meeting production goals effectively.

30 Oct 2023

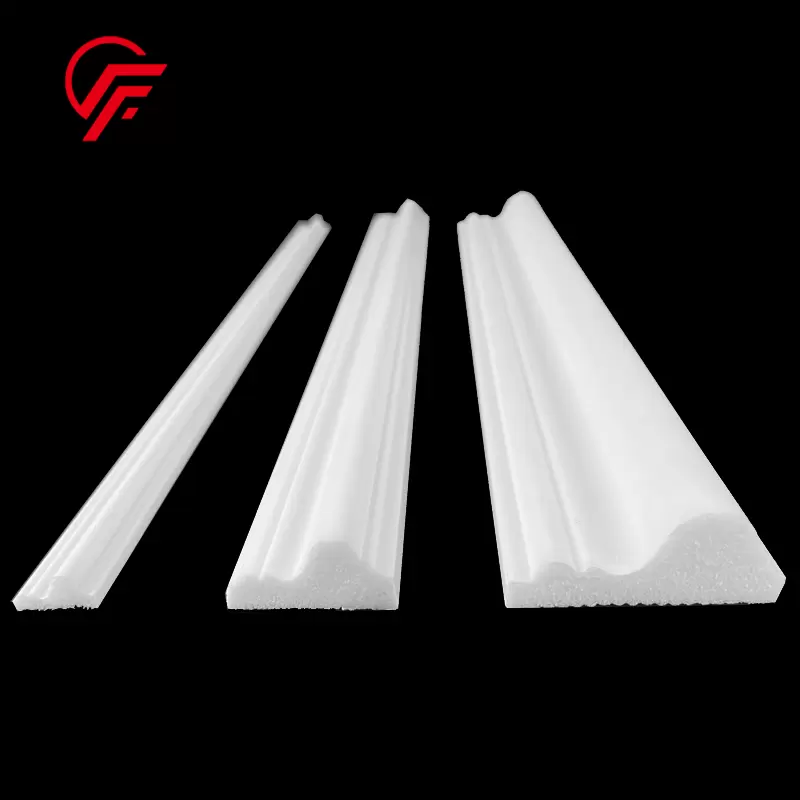

30 Oct 2023 How to Choose PS Decorative Lines?

Welcome to our blog post on how to choose the perfect PS Decorative Lines for your home or office! If you're looking to enhance the aesthetics of your space and add a touch of elegance, then PS Decorative Lines are the ideal solution. These decorative lines not only serve as beautiful accents but also provide functionality and durability.

19 Jul 2024

19 Jul 2024 Maximizing Efficiency with High-Performance Recycling Pelletizers

In today's fast-paced and environmentally conscious world, the need for efficient recycling solutions is more critical than ever. High-performance recycling pelletizers play a pivotal role in transforming plastic waste into reusable materials, contributing to both economic and environmental sustainability.