Technology

01

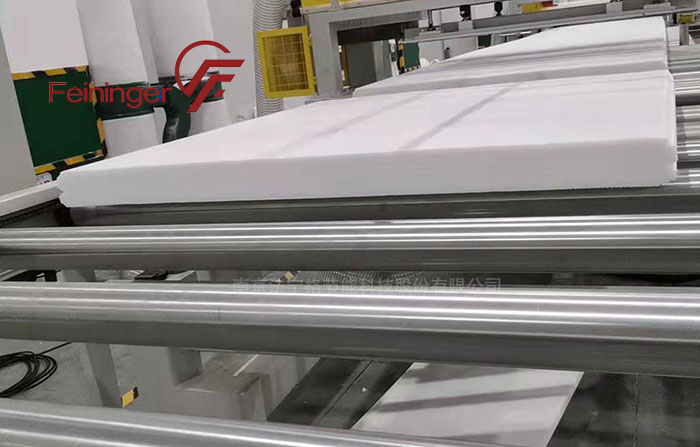

Sep . 2023Welcome to the world of wooden layer sandwich boards! These innovative and versatile building materials have been gaining popularity for their durability, strength, and aesthetic appeal. Whether you're a homeowner looking to enhance your living space or a construction professional seeking reliable solutions, wooden layer sandwich boards are an excellent choice.

In this blog post, we will take you through everything you need to know about these incredible boards – from how they are made to the benefits they offer. We will also highlight the five best types of wood commonly used in sandwich board manufacturing. So buckle up and get ready to explore the fascinating world of wooden layer sandwich boards!

But wait, before we dive into all that exciting information, let's first understand what exactly a wooden layer sandwich board is and why it has become such a sought-after material in various industries. Stay with us as we unravel its secrets!

Wooden layer sandwich boards are a versatile and durable option for various construction and insulation projects. If you're interested in making your own wooden layer sandwich board, here's a step-by-step guide to help you get started.

First, gather all the necessary materials. You'll need XPS foam sheets, wood veneer or plywood panels, adhesive glue, clamps, and cutting tools such as a saw or utility knife. Next, measure and cut the XPS foam sheets to the desired dimensions for your sandwich board. Make sure to account for any additional thickness from the wood layers. Once you have your foam sheets ready, apply adhesive glue evenly on one side of each sheet. Then carefully place the wood veneer or plywood panel onto the glued surface of one foam sheet. Press down firmly to ensure proper adhesion.

Repeat this process with another foam sheet on top of the first wood layer. Continue alternating between foam sheets and wood layers until you've reached the desired number of layers for your sandwich board. Clamp all the layers together tightly using C-clamps or other suitable clamping devices. Leave it undisturbed for several hours or overnight to allow the glue to fully cure and bond all the components together.

Once dry, remove any excess adhesive that may have squeezed out during clamping. Trim off any rough edges using a saw or utility knife if needed.

Voila! You now have your own homemade wooden layer sandwich board ready for use in various applications such as wall insulation or furniture construction.

Remember that safety precautions should always be observed when working with cutting tools and adhesives. It's also important to choose high-quality materials that can withstand environmental conditions over time.

So why not give it a try? Making your own wooden layer sandwich board is not only cost-effective but also allows customization according to your specific needs!

Wooden Layer Sandwich Boards offer a multitude of benefits that make them a popular choice for various applications. One of the key advantages is their durability. Made with layers of wood and XPS (extruded polystyrene) foam, these boards are able to withstand heavy loads and resist warping or cracking over time.

Another benefit is their versatility. Wooden layer sandwich boards can be used in both interior and exterior settings, making them suitable for a wide range of projects. Whether you need to create furniture, build partitions, or construct walls, these boards provide the strength and stability required.

In addition to their durability and versatility, wooden layer sandwich boards also offer excellent thermal insulation properties. The XPS foam core helps regulate temperature by reducing heat transfer through the board, resulting in energy savings and improved comfort levels.

Furthermore, these boards are lightweight compared to traditional solid wood panels or other construction materials like concrete or steel. This makes transportation and installation easier while still maintaining structural integrity.

Wooden layer sandwich boards provide an eco-friendly option as they utilize sustainable natural resources such as wood fibers combined with low carbon emission XPS foam core material.

With all these benefits combined - durability, versatility, thermal insulation properties, lightweight design and sustainability - wooden layer sandwich boards are an ideal choice for any project requiring reliable performance and long-lasting results.

When it comes to choosing the right wood for your sandwich board, durability and versatility are key factors to consider. Here are five of the best types of wood that are commonly used for sandwich boards:

1. Plywood: Plywood is a popular choice due to its strength and affordability. It is made by layering thin sheets of wood together with adhesive, resulting in a sturdy and stable material.

2. Medium-density fiberboard (MDF): MDF is known for its smooth surface and uniform consistency, making it ideal for painting or veneering. It offers great dimensional stability, which means it won't warp easily.

3. Particle board: Made from compressed wood particles and resin, particle board is a cost-effective option that provides good structural support. However, it may not be as durable as other types of wood.

4. Cedar: Known for its natural resistance to decay and insect damage, cedar is an excellent choice for outdoor sandwich boards. It also has a beautiful grain pattern that adds aesthetic appeal.

5. Oak: Oak is renowned for its strength and durability, making it suitable for heavy-duty applications such as construction site signage or traffic control boards.

Remember to choose the type of wood based on your specific needs – whether you prioritize longevity, appearance or cost-effectiveness!

Caring for your wooden layer sandwich board is essential to ensure its longevity and maintain its beautiful appearance. Here are some tips on how to properly care for your board:

1. Clean it regularly: After each use, wipe down the surface of the board with a damp cloth or sponge to remove any food debris. Avoid using harsh chemicals or soaking the board in water as this can damage the wood.

2. Oil it occasionally: To keep your wooden layer sandwich board well-hydrated and prevent it from drying out, apply a thin coat of food-grade mineral oil or beeswax periodically. This will help protect the wood from moisture absorption and reduce the risk of cracking or warping.

3. Avoid high temperatures: Direct exposure to extreme heat can cause the wood to warp or crack. Always place hot pots, pans, or dishes on trivets or heat-resistant pads before placing them on your wooden layer sandwich board.

4. Don't soak it: Wooden boards should never be soaked in water as this can cause swelling and distortion of the wood fibers.

5. Store it properly: When not in use, store your wooden layer sandwich board in a cool and dry place away from direct sunlight and humidity.

By following these simple care instructions, you can extend the life of your wooden layer sandwich board and continue enjoying its durability and versatility for years to come!

Wooden layer sandwich boards are an excellent choice for various applications due to their durability and versatility. These boards offer a unique combination of strength and beauty that makes them suitable for both indoor and outdoor use.

By following the steps outlined above, you can make your own wooden layer sandwich board and enjoy its many benefits. Remember to choose the right type of wood based on your specific needs, as each wood has its own strengths and characteristics.

Feininger is a leading manufacturer of high-quality wooden layer sandwich boards, including XPS sandwich panels with wood layers. Their expertise in producing durable and reliable products ensures that you will get a board that meets your expectations.

To prolong the lifespan of your wooden layer sandwich board, it's important to take proper care of it. Regular cleaning and maintenance will help prevent any damage or wear over time.

Whether you're using a wooden layer sandwich board for construction projects, signage, or furniture making, you can rely on its strength and longevity. The natural beauty of wood adds an aesthetic appeal that enhances any project or space.

Investing in a wooden layer sandwich board is not only practical but also provides long-term value. Its resistance to moisture, insects, and decay ensures that it will stand the test of time even in challenging environments.

So why wait? Explore the world of wooden layer sandwich boards today and discover how this versatile material can elevate your next project!

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

10 Jul 2024

10 Jul 2024 Common Challenges in PET Foam Sheet Production and How to Overcome Them

Producing high-quality PET foam sheets is an intricate process that involves multiple stages, from raw material preparation to extrusion and foaming. Despite the advanced technology and machinery used, manufacturers often face several challenges.

18 Mar 2025

18 Mar 2025 PS Skirting Production Line: A Revolutionary Advancement in Decorative Trim Manufacturing

Polystyrene (PS) skirting boards and moldings have long been essential components in interior and exterior decoration, offering durability, aesthetic appeal, and versatility.

17 Apr 2024

17 Apr 2024 Enhancing Product Quality: Applications of the Micro Supercritical CO₂&N₂ Injection Machine

In the realm of polymer processing and manufacturing, the Micro Supercritical CO₂&N₂ Injection Machine from China Feininger has revolutionized the industry with its ability to enhance product quality across various applications.