Technology

22

Mar . 2024Are you ready to revolutionize your production line with the latest in PS skirting board technology? Dive into the future of manufacturing efficiency and precision with our cutting-edge production line. Say goodbye to inefficiencies and hello to seamless operations that elevate your output quality. Stay ahead of the curve and meet market demands head-on. Are you prepared to transform your production process for optimal results?

PS skirting board production plays a pivotal role in the construction industry, offering durable and aesthetically pleasing solutions for finishing touches. These skirting boards provide a clean transition between walls and floors, enhancing the overall look of any space. Their ease of installation makes them a popular choice among builders and homeowners alike.

The versatility of PS skirting boards is unmatched, as they can be used in various settings such as residential homes, commercial buildings, and even industrial spaces. Their ability to come in different designs, sizes, and colors allows for customization to suit any interior style. Whether it's a modern office or a cozy living room, PS skirting boards can effortlessly blend in.

The market demand for PS skirting boards is on the rise due to their affordability, low maintenance requirements, and long-lasting durability. As more people recognize the benefits of using PS skirting boards, manufacturers are experiencing an increase in orders and inquiries. This surge in demand reflects the trust consumers have in the quality and functionality of these products.

To extrude PS skirting board profiles, the process involves melting polystyrene resin pellets in an extruder. The molten material is then forced through a die to form the desired skirting board shape. Cooling tanks help solidify the profile before cutting it to the required length.

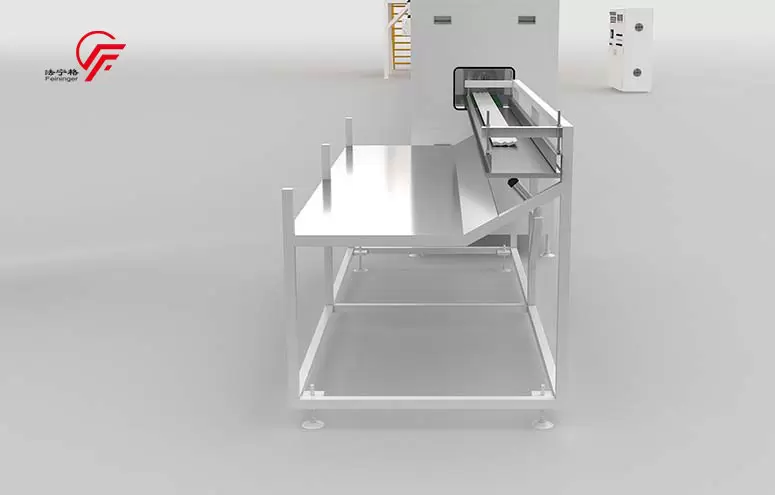

The Feininger XPS foaming profile extrusion line plays a crucial role in creating high-quality skirting boards. This advanced machinery enables precise control over the foaming process, resulting in consistent density and excellent surface finish for the profiles.

Using GPPS foam resin is essential in the extrusion process as it provides key properties to the skirting boards. This type of resin offers excellent impact resistance, thermal stability, and dimensional accuracy, ensuring that the final product meets quality standards.

The PS skirting frame making machine is equipped with advanced technology for precise and efficient production. It integrates a die that enables customization according to customer requirements, ensuring versatility in design options.

Each model comes with specific features tailored to diverse production needs. The machines are designed to deliver consistent quality output while maximizing operational efficiency. They are user-friendly, allowing operators to easily control and adjust parameters for seamless production processes.

The PS foamed skirting line machine comprises a feeder, which introduces the raw material into the system. The engineers have integrated a supercritical CO2 agent to facilitate the physical foaming process.

The machine's core functionality involves utilizing this innovative technology to achieve physical foaming instead of the traditional chemical foaming method. This shift results in superior quality products with optimized product density.

Once the raw material is fed into the machine through the feeder, the supercritical CO2 agent comes into play. It interacts with the material, inducing physical foaming that enhances the final product's characteristics.

The production of PS skirting boards begins with the careful selection and mixing of raw materials. These materials, including polystyrene resin and other additives, are blended to achieve the desired characteristics.

Once the raw materials are mixed, they undergo injection molding. During this process, the foaming agent is injected into the mixture. This step is crucial as it introduces tiny gas bubbles that expand within the material, creating a lightweight yet sturdy final product.

After injection molding and foaming, the next critical stage involves cooling the material rapidly. This rapid cooling process helps in setting the shape of the skirting board efficiently. The precision and speed at which this cooling occurs significantly impact the quality of the final product.

Before packaging, each skirting board undergoes rigorous quality control checks to ensure it meets industry standards. Any imperfections or defects are identified and rectified promptly to maintain high-quality standards. Finally, the finished skirting boards are carefully packaged for distribution.

PS skirting boards are known for their exceptional impact resistance, making them ideal for areas prone to knocks and bumps. This feature ensures that the boards maintain their quality and appearance over time.

The surface of PS skirting boards boasts water impermeability, preventing any damage from moisture or water exposure. This characteristic enhances the longevity of the boards, especially in humid environments.

With an independent bubble structure, PS skirting boards offer a unique design that contributes to their lightweight nature without compromising on strength. This structure also aids in easy installation and maintenance.

One significant advantage of PS skirting boards is their recyclability, aligning with sustainable practices and environmental consciousness. This feature makes them a preferred choice for eco-friendly projects.

PS skirting boards exhibit remarkable durability and temperature resistance, ensuring they can withstand varying climate conditions without warping or deteriorating. This durability factor adds to the overall reliability of these boards.

PS skirting boards offer the advantage of reduced density, making them lightweight and easy to handle during installation. This feature simplifies the mounting process, especially for DIY enthusiasts.

Emphasizing environmental friendliness, PS skirting boards are made from recyclable materials, reducing waste and promoting sustainability. This eco-friendly aspect appeals to environmentally conscious consumers.

The cost-effectiveness of utilizing PS skirting boards lies in their durable nature, requiring minimal maintenance over time. This results in long-term cost savings for homeowners and businesses alike.

With a high-performance ratio, PS skirting boards exhibit excellent durability and resistance to wear and tear. This quality ensures that the boards maintain their aesthetic appeal even in high-traffic areas.

One of the key advantages of PS skirting boards is their effectiveness in preventing dampness and mold issues. By acting as a protective barrier between walls and floors, these boards help maintain a dry and healthy indoor environment.

The Feininger XPS foaming profile extrusion line plays a crucial role in the production of PS skirting boards. This advanced machinery ensures precise shaping and consistent quality throughout the manufacturing process.

PS skirting boards are highly versatile, finding applications in various sectors. They are commonly used in creating elegant photo frames, adding a touch of sophistication to interior decor. These boards are ideal for door frame boards, providing durability and aesthetic appeal simultaneously. Moreover, they serve as excellent alternatives to traditional wood moldings, offering a cost-effective solution for achieving wood-like moldings.

The quality of PS skirting boards is unmatched, boasting exceptional durability and resistance to wear and tear. Their versatility shines through in construction projects, where they excel in both residential and commercial settings. Whether it's concealing wiring or enhancing the visual appeal of a room, PS skirting boards deliver on both functionality and aesthetics.

In exploring PS skirting board production, you've gained valuable insights into the intricate process of creating these versatile home improvement elements. Understanding the production line, extrusion techniques, and key features equips you with the knowledge to make informed decisions when selecting skirting boards for your projects. The advantages of PS skirting boards go beyond aesthetics, offering durability, ease of installation, and a cost-effective solution for enhancing your living spaces.

As you delve deeper into the world of PS skirting board production, consider how these insights can elevate your next renovation or construction endeavor. By harnessing this knowledge, you can confidently choose the best-suited skirting boards for your needs, ensuring a seamless and stylish finish to any room. Take the next step in transforming your space with the right PS skirting boards tailored to your preferences and requirements.

Yes, PS skirting boards can be customized to specific sizes based on your requirements. This customization allows for a perfect fit in various spaces and ensures a tailored solution for your needs.

PS skirting boards offer benefits such as durability, moisture resistance, easy installation, and versatility in design. They are also cost-effective and require minimal maintenance, making them a practical choice for interior finishing solutions.

The production process involves extruding PS material into the desired profile, forming frames using specialized machinery, and implementing a foamed skirting line machine for enhanced features. The detailed process ensures high-quality and consistent output of PS skirting boards.

PS skirting boards are known for their lightweight nature, impact resistance, smooth finish, and ability to mimic wood textures. They offer flexibility in design choices and can easily adapt to different interior styles, providing a modern touch to spaces.

When selecting PS skirting boards, focus on descriptions that emphasize their quality construction, precise dimensions, color options, surface finishes, and compatibility with various decor styles. These aspects ensure you choose skirting boards that meet both aesthetic and functional requirements.

<Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

05 Sep 2024

05 Sep 2024 Streamlining Operations with the Latest XPS Cornice Production Line Innovations

In today's competitive manufacturing landscape, businesses are always seeking ways to streamline operations, reduce costs, and enhance productivity.

14 Nov 2024

14 Nov 2024 Troubleshooting Common Issues with PET Foam Extruder Machines

PET foam extruder machines are essential in the production of lightweight, durable, and versatile materials used across various industries, including packaging, automotive, and construction.

19 Feb 2024

19 Feb 2024 Partition Wall Panel: Overview and Versatile Solutions

Looking to enhance your space with versatility and style? Consider the practical solution of a partition wall panel. These panels offer a flexible way to divide areas, create privacy, and add a modern touch to any room.