Technology

13

Jun . 2024Are you looking for a game-changing solution to revolutionize your construction projects? Look no further than XPS with PVC sandwich panels. These innovative panels are making waves in the industry, offering a host of benefits that can enhance both the efficiency and sustainability of your building endeavors. In this blog post, we'll dive deep into what makes XPS with PVC sandwich panels so special and explore how they can elevate your construction projects to new heights. So buckle up and get ready to discover a world of possibilities!

XPS with PVC sandwich panels are a cutting-edge construction material that combines the strength and durability of extruded polystyrene (XPS) foam with the versatility and aesthetic appeal of polyvinyl chloride (PVC) facing. These panels consist of a rigid foam core, typically made from XPS, sandwiched between two layers of PVC.

One key feature that sets XPS with PVC sandwich panels apart is their exceptional insulation properties. The closed-cell structure of the XPS foam provides excellent thermal resistance, minimizing heat transfer and reducing energy consumption for heating or cooling purposes. This makes them an ideal choice for creating energy-efficient buildings that can help reduce environmental impact and lower utility costs.

In addition to their insulation capabilities, XPS with PVC sandwich panels offer remarkable structural integrity. The combination of the rigid foam core and durable PVC facing creates a robust panel that can withstand various external forces while maintaining its shape and stability. This makes them suitable for both load-bearing applications as well as decorative purposes.

Moreover, these panels are highly versatile in terms of design possibilities. With a wide range of colors, textures, and finishes available in the PVC facing layer, architects and designers have ample creative freedom to achieve their desired aesthetics. Whether you're aiming for a sleek modern look or a more rustic feel, XPS with PVC sandwich panels can provide the perfect solution to bring your vision to life.

Furthermore, installation is relatively straightforward when it comes to these panels. They can be easily cut into desired dimensions on-site using standard tools without any specialized equipment required. This ensures quick turnaround times during construction projects.

XPS with PVC sandwich panels offer an innovative approach to construction materials by combining superior insulation performance, structural strength, and design versatility into one product. By incorporating these revolutionary panels into your building projects, you'll not only benefit from increased energy efficiency but also create visually stunning spaces that stand the test of time.

When it comes to construction, it's crucial to choose materials that are not only durable but also lightweight and easy to install. This is where XPS with PVC sandwich panels come in. These panels are made by combining a rigid foam material called extruded polystyrene (XPS) with layers of PVC on both sides.

One advantage of using XPS with PVC sandwich panels is their excellent insulation properties. The combination of XPS foam and PVC creates a structure that effectively blocks heat transfer, keeping the building cool in summer and warm in winter. This can lead to significant energy savings and reduced reliance on heating or cooling systems.

Another benefit is the durability of these panels. The XPS core provides strength and stability while the outer layers of PVC offer protection against weathering, impact, and moisture. This makes them ideal for exterior applications where resistance to harsh elements is necessary.

In addition, XPS with PVC sandwich panels are lightweight yet sturdy, making installation quick and efficient. They can be easily cut into various sizes and shapes as needed without compromising their structural integrity.

Furthermore, these panels have excellent fire-resistant properties due to the non-combustible nature of XPS foam. This enhances safety measures within buildings by minimizing the risk of fire spread.

The advantages offered by XPS with PVC sandwich panels make them an attractive choice for construction projects ranging from residential homes to commercial buildings. Their insulation properties, durability, ease of installation, and fire resistance contribute towards creating sustainable structures that meet modern standards for efficiency and safety.

Installing XPS with PVC sandwich panels may seem like a daunting task, but with the right approach and guidance, it can be accomplished smoothly. Here's a step-by-step guide on how to install these panels effectively.

Ensure that the surface where you will be installing the panels is clean and free from any debris. This will provide a smooth base for adherence. Next, measure and mark the desired dimensions of each panel on the surface using a measuring tape and pencil.

Before applying adhesive, make sure to wear protective gloves as some adhesives contain chemicals that can irritate the skin. Apply an even layer of adhesive onto both the backside of the panel and onto your marked area on the surface.

Once adhesive has been applied, carefully position each panel onto its designated spot while ensuring proper alignment. Press firmly against each panel to create strong contact between the adhesive and substrate.

To further enhance stability, use screws or nails along with adhesive for additional support. Be cautious not to over-tighten screws or nails as this may cause damage to both panels and underlying surface.

Allow sufficient time for curing before proceeding with any further construction activities. This will ensure that panels are securely in place before moving forward.

By following these simple steps, you'll achieve a successful installation of XPS with PVC sandwich panels in your construction project!

XPS with PVC sandwich panels can be used in various applications within the construction industry. Their versatility and durability make them an ideal choice for a wide range of projects.

One common use for these panels is in walls and partitions. Due to their excellent thermal insulation properties, XPS with PVC sandwich panels are often used to create energy-efficient walls that help maintain a comfortable indoor temperature while reducing heating and cooling costs.

Another application is in roofing systems. The lightweight nature of the panels makes them easy to install, while their high strength ensures long-lasting protection against weather elements such as rain, snow, and UV radiation. Additionally, the PVC outer layer provides excellent resistance to corrosion and chemicals, making it suitable for areas exposed to harsh environmental conditions.

These panels are also commonly employed in flooring applications. Thanks to their rigid structure and impact resistance, they can withstand heavy loads without deforming or cracking. This makes them suitable for both residential and commercial spaces where durability is essential.

In addition to walls, roofs, and floors, XPS with PVC sandwich panels can also be used in ceilings, doors, furniture manufacturing, cold storage facilities, modular buildings—the possibilities are endless! Their versatility allows architects and builders to get creative while still benefiting from the advantages offered by these panels.

By using XPS with PVC sandwich panels across different applications within a construction project—be it residential or commercial—a consistent level of quality can be achieved throughout the entire space. This not only enhances aesthetics but also improves overall functionality and longevity.

In conclusion, XPS with PVC sandwich panels find extensive use in construction due to their numerous benefits ranging from insulation properties to durability. Architects have ample opportunities when incorporating these versatile materials into various aspects of building design—walls, roofs, floors, ceilings, doors, furniture manufacturing, cold storage facilities and modular buildings.

XPS with PVC sandwich panels have emerged as a game-changer in the construction industry, providing numerous advantages that make them an ideal choice for various applications. From enhanced insulation properties to durability and easy installation, these panels offer a range of benefits that cannot be overlooked.

Their ability to provide superior thermal insulation helps improve energy efficiency in buildings, reducing heating and cooling costs significantly. The lightweight nature of XPS with PVC sandwich panels makes them easier to handle and install, saving time and effort during construction projects. Additionally, their resistance to moisture ensures long-lasting performance even in challenging environments.

The versatility of these panels allows for their application in various areas such as walls, roofs, floors, and partitions. Whether it's residential or commercial projects or even portable structures like modular homes or temporary shelters, XPS with PVC sandwich panels can deliver exceptional results.

XPS with PVC sandwich panels are revolutionizing the way we construct buildings by offering unmatched advantages over traditional building materials. With their remarkable insulation capabilities and ease of installation, these panels not only contribute to energy-saving but also ensure durability and longevity. As the demand for sustainable construction practices continues to grow, incorporating XPS with PVC sandwich panels into building projects is undoubtedly a wise choice for both builders and property owners alike.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

08 Dec 2023

08 Dec 2023 How to choose extruded board manufacturers?

There are a variety of thermal insulation products in the building thermal insulation material market, and extruded plastic boards are favored by consumers because of their health and environmental protection and excellent physical and chemical properties.

07 Mar 2024

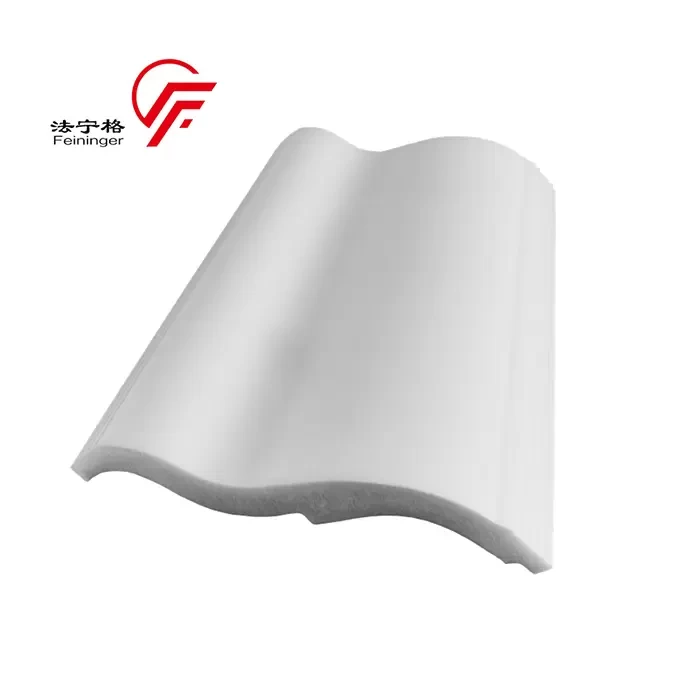

07 Mar 2024 XPS Decorative Moulding: Enhance Interiors with Style

Are you seeking to elevate your space with a touch of elegance and sophistication? Look no further than XPS decorative moulding. Transforming ordinary rooms into extraordinary spaces, XPS decorative moulding offers a seamless way to add charm and character to your home or office.

11 Oct 2023

11 Oct 2023 How to choose XPS extrusion board production line?

Choosing an XPS extruded board production line is a significant investment for any manufacturing operation. Feininger being the first professional manufacturer of XPS extrusion board production lines in China may be a viable option.