Technology

11

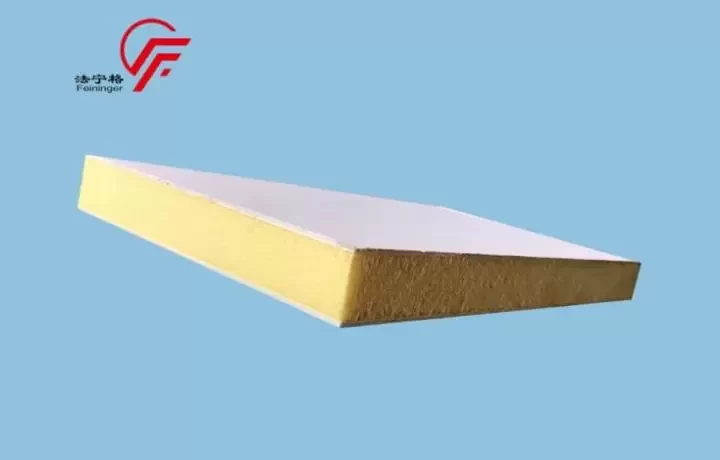

Oct . 2023Usually, XPS extruded board production line is tailored to the requirements of the enterprise. So before you invest, you need to know a little bit about how to configure the XPS extrusion board line to make the most of your investment. XPS stands for extruded polystyrene. The first thing to know is the output. What's the capacity What are you looking for? For example, 500kg/ h or 1.5 t/h when the capacity changes. In addition, the output has some connection to your product category. If the thickness of the product is 20mm or less, I do not recommend that your production line exceed 300kg/hr. Vice versa, if you will be producing XPS plates with thickness greater than 100mm, I would recommend more than 1000kg/hr, as greater thickness requires greater pressure gradients.

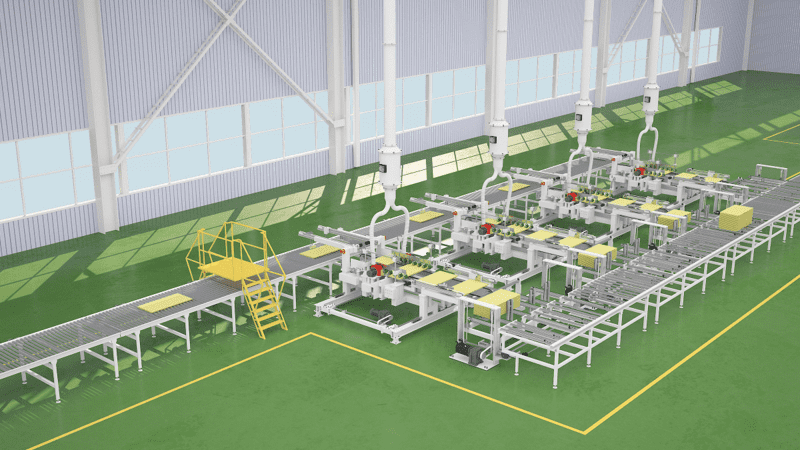

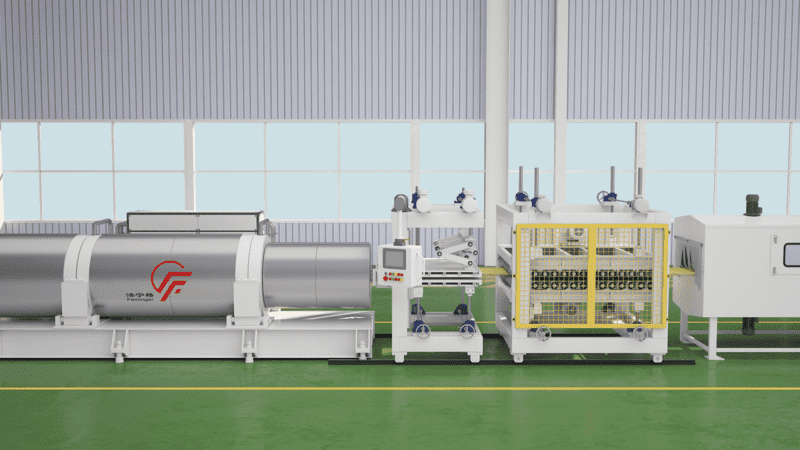

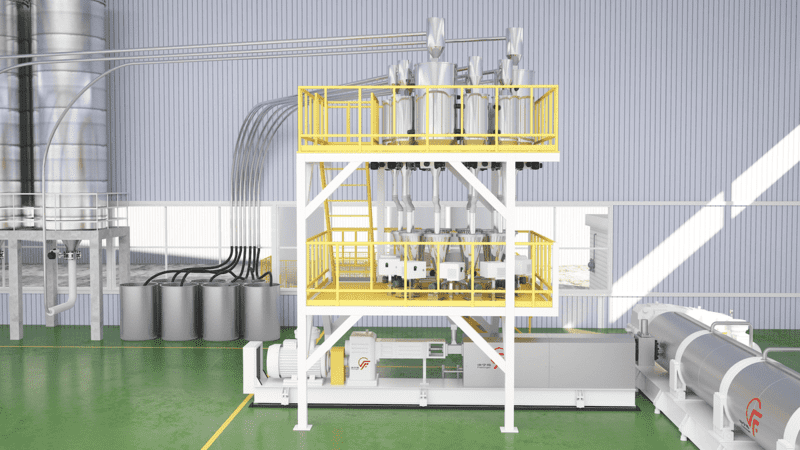

Today's XPS extruded plate production line features a tandem extrusion system with two stages for the primary extruder and secondary extruder. Single screw and single screw extruder or twin screw extruder screw and single screw extruder. Single-stage twin-screw extrusion system obsolete about 10 years ago Generally, the XPS extrusion board production line consists of the feed system, the extrusion system, the die, and the downstream first, the feeding system. There are three main feed systems, weight loss, gravimetric analysis, and screw feed. They also have a big price difference.

Part loss vacuum loading system in weight feeding system. In a weight-loss feeding system, each material will be batched and delivered continuously. Each unit has its own weight sensor. Any pellet or powder can reduce the weight of the feeding system very well. Each feed range material can be quite large.

Gravity feed system. In gravity feeding systems, each material will be batched in batches and then mixed before feeding. It has only one weight sensor.

Both weight loss and gravimetric analysis can be used. However, twin-screw extruders are single-screw extruders that are only suitable for gravimetric analysis, because the distribution efficiency of hybrid single-screw extruders is insufficient compared to twin-screw extruders. This gravity feed system has the following tendencies:When your raw material contains powder, such as talc or paint; This stratification will slightly affect the mixing and distribution of materials, so if you are using a gravity feed system, you are better off using all granular materials. Weight feed systems are relatively cheaper than weight loss.

Choosing an XPS extruded board production line is a significant investment for any manufacturing operation. Feininger being the first professional manufacturer of XPS extrusion board production lines in China may be a viable option.

Lying in Nanjing Tangshan Industrial Area, Feininger (Nanjing) Energy Saving Technology Co., Ltd (shortened as Feininger) is established in the year 2001 and covers an area of 70 acres. Feininger is the first professional manufacturer of XPS Extrusion Line and XPS Foam Board here in China. At the same time we are the unique enterprise specializing in XPS Foam as well as developing, manufacturing and selling of XPS equipment.

As demonstration enterprise appointed by World Environment-protection Organization, National High-tech Enterprise, Jiangsu Provincial Enterprise in Building Efficiency, Feininger bears Innovation through her developing. The professional R& D center of Feininger has close co-operations with some academies and research institutions. In the year of 2002, Feininger firstly design and manufacture high quality XPS Foam Board Production Line in China. Since then we have contributed to research of XPS technology, continuously improved the product, which enables us to be leader in XPS foaming industry home and abroad.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

18 Feb 2025

18 Feb 2025 Step-by-Step Guide to Setting Up an XPS Foam Board Production Line

The demand for high-quality, energy-efficient insulation materials has grown significantly in recent years, and one of the most popular choices for insulation is XPS foam board.

29 Sep 2024

29 Sep 2024 Applications of ETPU Foam Particles in Automotive and Industrial Products

In recent years, ETPU (Expanded Thermoplastic Polyurethane) foam particles have garnered significant attention across various industries, particularly in automotive and industrial applications. Known in the industry as "magic particles," ETPU is celebrated for its impressive properties, including high resilience, lightweight composition, and versatility.

05 Nov 2024

05 Nov 2024 From Lab to Industry: Applications of the Beads Foam Experiment Machine

In the world of material science and manufacturing, innovation is driven by advanced research and testing technologies. One such technological marvel is the Beads Foam Experiment Machine, particularly designed for testing thermoplastic materials like PBAT, PA, and PET.