Technology

30

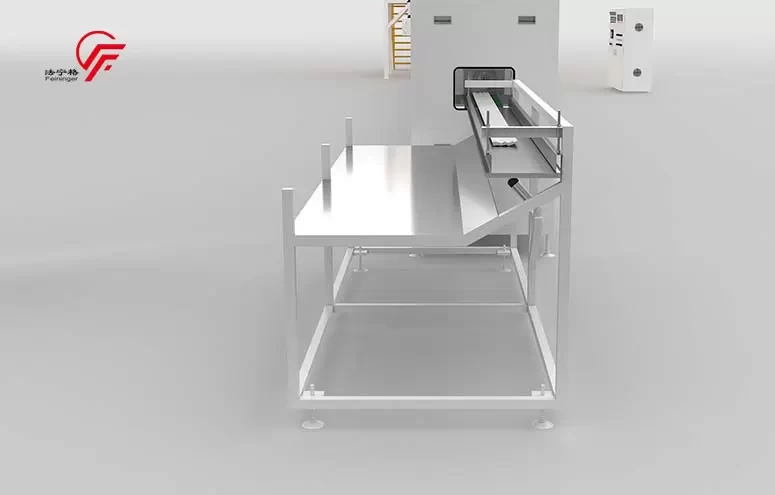

Jul . 2024Proper maintenance of your beads foam experiment machine is essential to ensure its longevity and optimal performance. Whether used in universities, research institutions, or industrial production lines, keeping your equipment in top shape can save you time, money, and headaches. China Feininger, a leading provider of PBAT/PA/PET and other thermoplastic physical foaming test equipment, offers expert advice on how to maintain your beads foam experiment machine effectively.

Regular cleaning is crucial to prevent buildup of residues that can affect the performance of your beads foam experiment machine. Residues can cause blockages and affect the accuracy of your experiments.

Regular inspections help identify wear and tear early, allowing for timely repairs and replacements. This can prevent unexpected breakdowns and extend the lifespan of your machine.

Proper lubrication of moving parts reduces friction, preventing wear and ensuring smooth operation. It also helps maintain the accuracy and precision of the machine.

Regular calibration ensures that your beads foam experiment machine provides accurate and reliable results. This is particularly important in research and industrial applications where precision is critical.

Keeping the machine's software up to date ensures you have the latest features, improvements, and security patches. This can enhance the machine’s performance and prevent software-related issues.

Professional servicing ensures that your beads foam experiment machine is maintained to the highest standards. Technicians can perform detailed inspections and repairs that may be beyond routine maintenance.

Maintaining your beads foam experiment machine is essential for its longevity and performance. By following these maintenance tips from China Feininger, you can ensure that your PBAT/PA/PET and other thermoplastic physical foaming test equipment remains in optimal condition, providing accurate and reliable results for your research or production needs. Regular cleaning, inspections, lubrication, calibration, software updates, and professional servicing are all critical components of an effective maintenance routine.

For more information on maintaining your beads foam experiment machine or to learn about China Feininger's range of thermoplastic physical foaming test equipment, visit our website or contact our support team today.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

16 Aug 2023

16 Aug 2023 Difference Between Physical Foaming and Chemical Foaming

Foam, with its unique structure and versatile properties, can be crafted using various methodologies, primarily bifurcated into two dominant techniques: physical and chemical foaming. Though both aim to introduce air bubbles or pockets into materials, the mechanisms and intricacies behind each process are markedly different.

14 Nov 2024

14 Nov 2024 Troubleshooting Common Issues with PET Foam Extruder Machines

PET foam extruder machines are essential in the production of lightweight, durable, and versatile materials used across various industries, including packaging, automotive, and construction.

14 Mar 2025

14 Mar 2025 Common Challenges in PS Skirting Production and How to Overcome Them

Polystyrene (PS) skirting boards have become a popular choice for interior and exterior decoration due to their lightweight nature, durability, and resistance to moisture. However, manufacturers often face several challenges in the production process, which can impact efficiency, quality, and sustainability.