Technology

24

May . 2024Underfloor heating systems are becoming increasingly popular due to their efficiency, comfort, and space-saving benefits. At the heart of an effective underfloor heating system is the insulation board. This guide will delve into the benefits and applications of underfloor heating grooved insulation boards, focusing on the high-quality products offered by China Feininger.

An underfloor heating grooved insulation board is a specialized component designed to enhance the efficiency and effectiveness of underfloor heating systems. The board is composed of high-strength XPS (extruded polystyrene) with an aluminum film heat-spreading layer attached to its surface. Feininger’s underfloor heating panels are grooved XPS foam boards with aluminum foil panels, prefabricated in the factory and assembled on-site. The surface features grooves at fixed intervals for laying heating pipes, ensuring optimal heat distribution and ease of installation.

One of the primary benefits of using underfloor heating grooved insulation boards is the significant improvement in energy efficiency. The high-strength XPS material provides excellent thermal insulation, reducing heat loss and ensuring that more heat is directed into the living space. The aluminum film layer further enhances heat distribution, making the system more efficient and cost-effective.

The grooves in the insulation boards are designed to hold the heating pipes securely in place, ensuring even spacing and uniform heat distribution across the floor. This results in a more comfortable and consistent temperature throughout the room, eliminating cold spots and ensuring a cozy living environment.

Feininger’s underfloor heating panels are prefabricated in the factory, simplifying the on-site assembly process. The grooves at fixed intervals make it easy to lay the heating pipes accurately and efficiently, reducing installation time and labor costs. This user-friendly design makes the installation process straightforward, even for those with limited experience.

Underfloor heating systems, in general, are a space-saving solution compared to traditional radiators. By integrating the heating system into the floor, you free up wall and floor space, allowing for more flexible interior design and furniture placement. This is particularly beneficial in smaller homes and apartments where space is at a premium.

The high-strength XPS material used in Feininger’s grooved insulation boards is not only an excellent insulator but also highly durable. It can withstand the pressures of daily use and the installation process, ensuring a long lifespan for the underfloor heating system. The aluminum film layer also protects the XPS board and enhances its longevity.

Underfloor heating grooved insulation boards are ideal for residential applications, including houses, apartments, and condominiums. They provide a comfortable and efficient heating solution that enhances the living environment while reducing energy costs.

In commercial settings, such as offices, retail stores, and restaurants, underfloor heating systems offer a discreet and efficient heating solution. The use of grooved insulation boards ensures quick and easy installation, minimizing disruption to business operations.

Healthcare facilities, including hospitals and clinics, benefit from the consistent and comfortable warmth provided by underfloor heating systems. The even heat distribution and energy efficiency of grooved insulation boards make them a preferred choice for such environments.

Schools, colleges, and universities can also benefit from underfloor heating systems. The efficient and uniform heating provided by grooved insulation boards creates a comfortable learning environment while keeping energy costs low.

Public buildings, including libraries, museums, and community centers, can use underfloor heating systems to maintain a comfortable indoor climate. The durability and longevity of Feininger’s grooved insulation boards make them a reliable choice for such applications.

Underfloor heating grooved insulation boards, such as those offered by China Feininger, are an essential component of efficient and effective underfloor heating systems. With their high-strength XPS composition, aluminum film heat-spreading layer, and prefabricated grooves for heating pipes, these boards offer numerous benefits, including enhanced energy efficiency, uniform heat distribution, ease of installation, space-saving solutions, and durability. Suitable for a wide range of applications, from residential buildings to public facilities, Feininger’s underfloor heating panels are a smart investment for any project aiming to achieve optimal heating performance and comfort.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

13 Oct 2023

13 Oct 2023 See You At The 134rd China Import and Export Fair

The China Import and Export Fair (Canton Fair), founded on April 25, 1957, is held in Guangzhou every spring and autumn, jointly sponsored by the Ministry of Commerce and the People's Government of Guangdong Province, and undertaken by China Foreign Trade Center.

03 Jan 2025

03 Jan 2025 Understanding the Technology Behind EPS Floor Heating Sheets for Better Heat Distribution

Floor heating systems have evolved significantly over the years, and one of the most innovative advancements is the development of EPS floor heating sheets.

23 Sep 2024

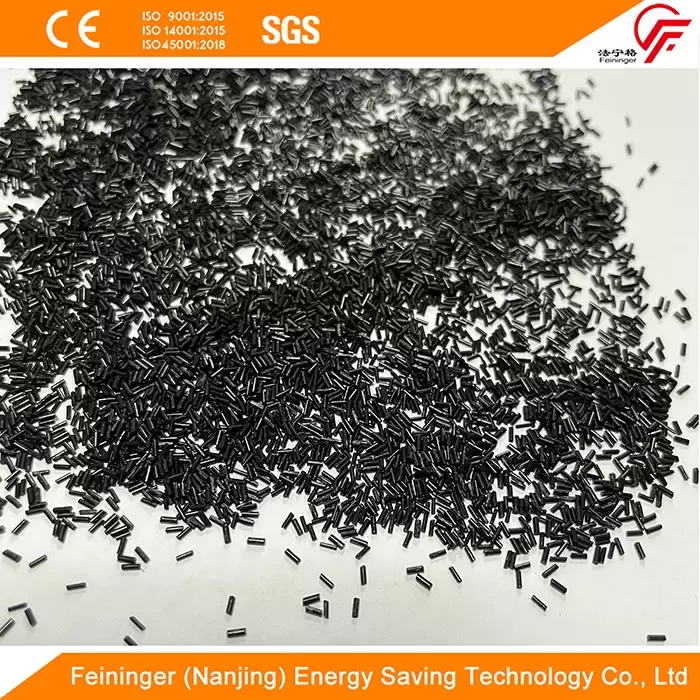

23 Sep 2024 EPS Graphite Particles vs. Traditional EPS: What’s the Difference?

In the world of materials engineering, the demand for lightweight, durable, and efficient insulation solutions has led to significant innovations. One such development is the introduction of EPS (Expanded Polystyrene) Graphite Particles, which offer distinct advantages over traditional EPS.