Technology

05

Jun . 2024In the ever-evolving landscape of manufacturing, efficiency and innovation are paramount. As industries across the globe strive to enhance production capabilities, the focus on advanced technologies such as EPP particle line technology has become more pronounced. EPP, or Expanded Polypropylene, is a revolutionary foam plastic known for its high crystallization polymer/gas composite material. Its unique properties make it an ideal choice for various applications. In this article, we will explore how optimizing your production with advanced EPP particle line technology can significantly benefit your operations.

Expanded Polypropylene (EPP) is a versatile material recognized for its exceptional performance. It is a high crystallization polymer/gas composite material, which makes it a superior choice for environmental protection, compressive buffering, and heat insulation. The unique characteristics of EPP include its light weight, strong plasticity, and excellent shock absorption. These attributes make EPP highly suitable for use in automotive, aviation, and electronics industries.

At the heart of optimizing production with EPP is the utilization of specialized EPP particle equipment. This equipment is designed to process polypropylene into expanded particles that retain the material's advantageous properties. The EPP particle equipment ensures uniform particle size and consistent quality, which is crucial for maintaining high standards in manufacturing processes.

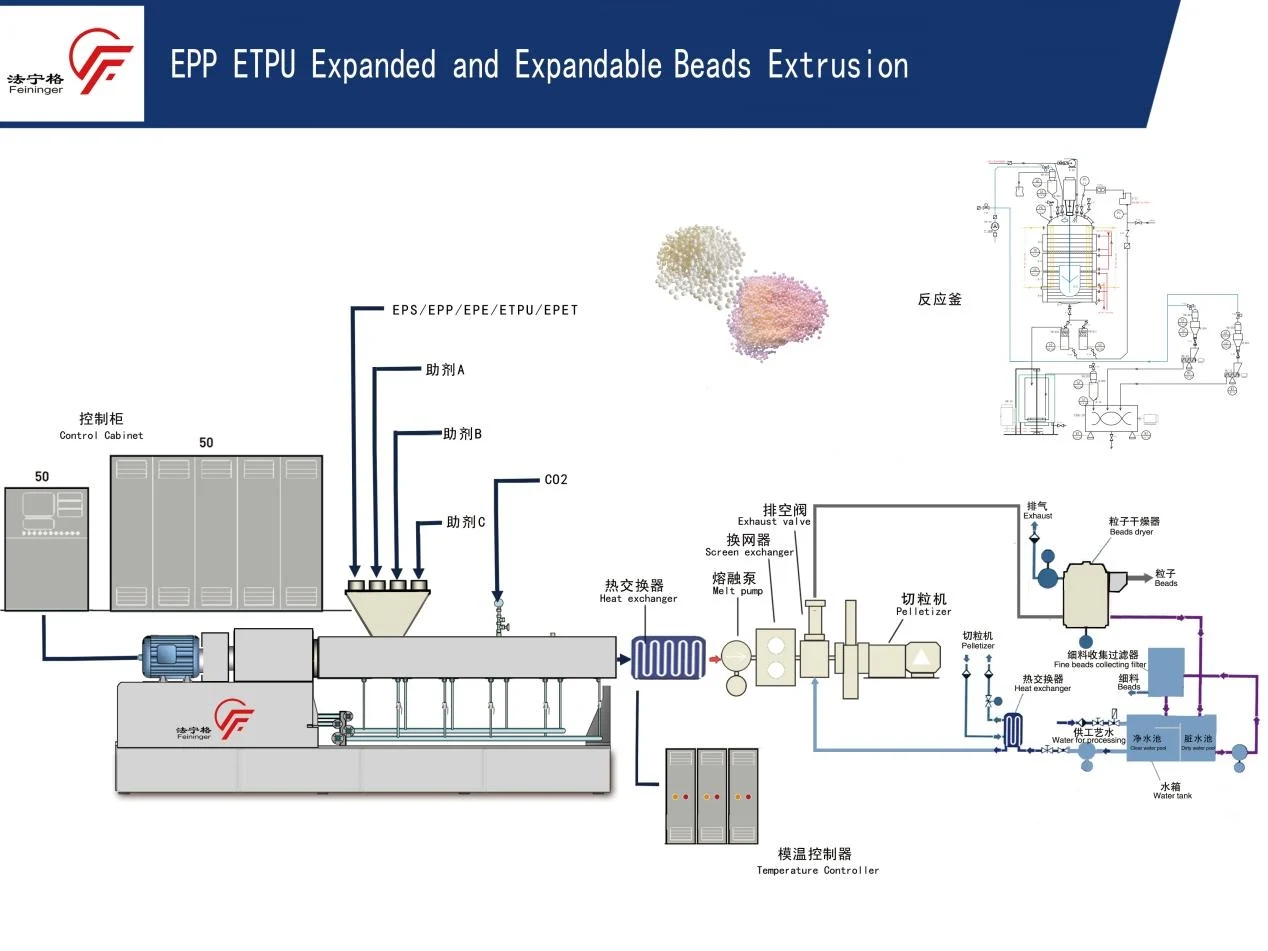

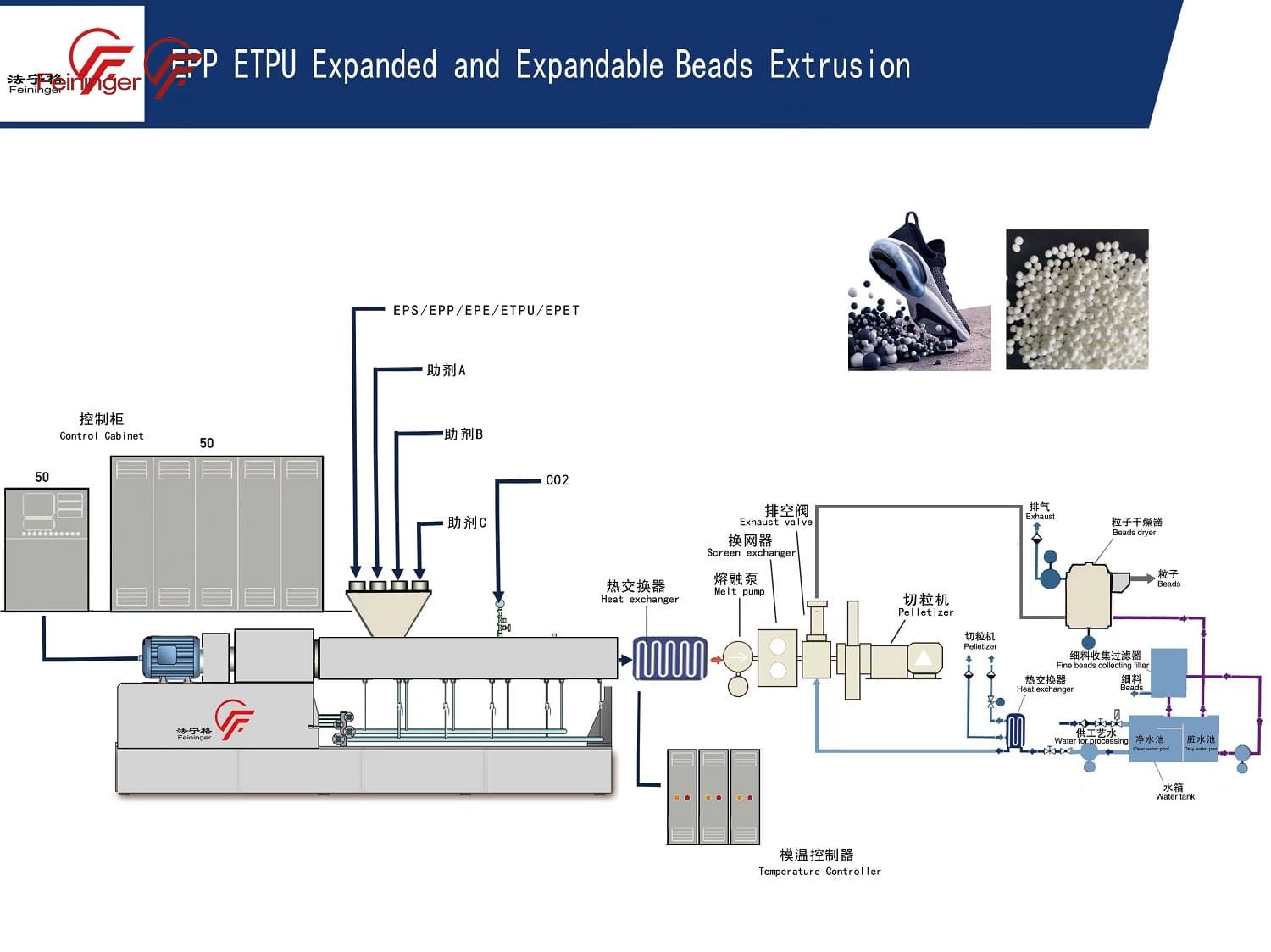

Implementing an advanced EPP particle line is a game-changer for any production facility. This technology streamlines the production process, ensuring efficient and continuous operation. The EPP particle line integrates various stages of production, from raw material feeding and pre-expansion to molding and final product processing. By automating these processes, manufacturers can achieve higher output rates and reduce manual labor costs.

Choosing the appropriate EPP particle machine is critical for maximizing the benefits of this technology. A high-quality EPP particle machine not only enhances production efficiency but also ensures product consistency and quality. When selecting an EPP particle machine, it's essential to consider factors such as machine capacity, energy efficiency, and ease of maintenance. Collaborating with a reputable EPP particle machine supplier, like China Feininger, can provide access to state-of-the-art machinery that meets industry standards.

Partnering with a reliable EPP particle machine supplier, such as China Feininger, offers numerous advantages. A trusted supplier provides not only top-tier equipment but also comprehensive support, including installation, training, and maintenance services. This partnership ensures that your production line operates smoothly and efficiently, minimizing downtime and maximizing productivity.

The advancements in EPP particle making machines have revolutionized the manufacturing process. Modern machines are equipped with cutting-edge technology that allows for precise control over particle expansion, density, and uniformity. These innovations result in products that meet the highest quality standards while optimizing material usage and reducing waste.

Optimizing your production with advanced EPP particle line technology offers significant benefits, including increased efficiency, improved product quality, and reduced operational costs. By leveraging state-of-the-art EPP particle equipment and partnering with a reputable supplier like China Feininger, manufacturers can stay ahead of the competition and meet the growing demands of various industries. Embracing this technology is a strategic move that can drive your business towards greater success and sustainability.

In summary, EPP particle line technology represents a pivotal advancement in manufacturing, providing a robust solution for producing high-quality, environmentally friendly products. With its unique properties and wide range of applications, EPP is set to continue playing a crucial role in the future of industrial production.

Mobile Phonel: +86-13776668008

Email: market@feininger.cn

Website: http://www.xpsmachine.com/

Address: No.2 Zhonglin Road,TangshanIndustry Area,Nanjing City, JiangsuProvince,China

Latest News

26 Feb 2024

26 Feb 2024 Feininger to Showcase Cutting-Edge XPS Technology at UzBuild - Uzbekistan International Exhibition 2024

Feininger, the pioneering manufacturer of XPS Extrusion Line and XPS Foam Board based in China, is poised to make a significant impact at the highly anticipated UzBuild - Uzbekistan International Exhibition 2024.

09 Nov 2023

09 Nov 2023 Feininger high-strength Cold Storage Extruded Plastic Panels

In addition to important factors such as thermal efficiency and moisture resistance, the insulation of extruded panels in refrigerated cold storage needs to have sufficient compressive strength characteristics.

26 Sep 2023

26 Sep 2023 Feininger and Western University jointly developed a one-step method to produce ETPU "popcorn", which is a boon to the industry

ETPU, or foamed TPU, commonly known as "popcorn", is currently the most elastic foam particle on the market. After pressure, heating and foaming treatment, the TPU particle volume will increase by 10 times, forming a honeycomb of non-crosslinked foam particles containing tiny closed bubbles, called ETPU.