Technology

02 Apr 2025

02 Apr 2025 ETPU Beads Foam Production Line: Key Features and Innovations for Modern Foam Manufacturing

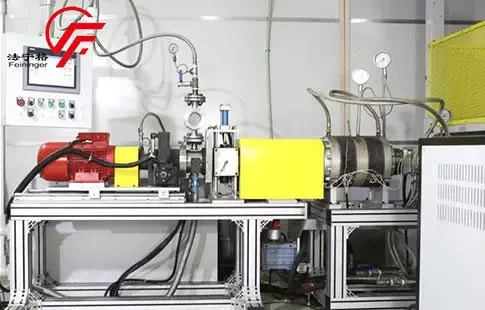

Central to the production of ETPU foam is the ETPU Beads Foam Production Line, a sophisticated system that integrates cutting-edge technology to ensure the highest levels of performance and quality.

28 Mar 2025

28 Mar 2025 Role of ETPU Beads Foam Production Lines in Enhancing Shock Absorption Technologies

In today's world, shock absorption is a key factor in various industries, from automotive manufacturing to sports equipment design and even packaging materials. One of the most effective materials for shock absorption is ETPU foam, a high-performance material known for its lightweight, resilient, and durable characteristics.

18 Mar 2025

18 Mar 2025 PS Skirting Production Line: A Revolutionary Advancement in Decorative Trim Manufacturing

Polystyrene (PS) skirting boards and moldings have long been essential components in interior and exterior decoration, offering durability, aesthetic appeal, and versatility.

14 Mar 2025

14 Mar 2025 Common Challenges in PS Skirting Production and How to Overcome Them

Polystyrene (PS) skirting boards have become a popular choice for interior and exterior decoration due to their lightweight nature, durability, and resistance to moisture. However, manufacturers often face several challenges in the production process, which can impact efficiency, quality, and sustainability.

05 Mar 2025

05 Mar 2025 How PET Foam Sheet Production Lines Improve Efficiency and Reduce Waste

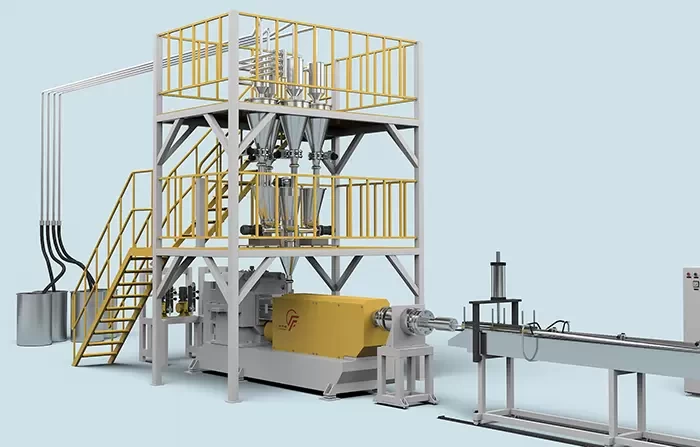

China Feininger, a leading manufacturer in XPS and PET foam extrusion technology, has developed high-performance PET foam sheet production lines that not only enhance manufacturing efficiency but also significantly reduce environmental impact.

28 Feb 2025

28 Feb 2025 Exploring the XPS Cornice Production Line: Key Benefits and Features

In the ever-evolving world of construction and architectural design, XPS (extruded polystyrene) foam is rapidly gaining popularity as a versatile material for moldings and decorative elements.